In short, the low friction of PTFE washers directly benefits mechanical systems by drastically reducing wear on moving components, which lowers energy consumption and extends the overall lifespan of the equipment. This inherent "slipperiness" allows parts to slide against each other with minimal resistance, improving operational efficiency.

The core value of PTFE's low friction is its ability to create self-lubricating systems. This eliminates the need for external oils or greases, enhancing reliability and enabling high performance in environments where traditional lubricants are impractical or forbidden.

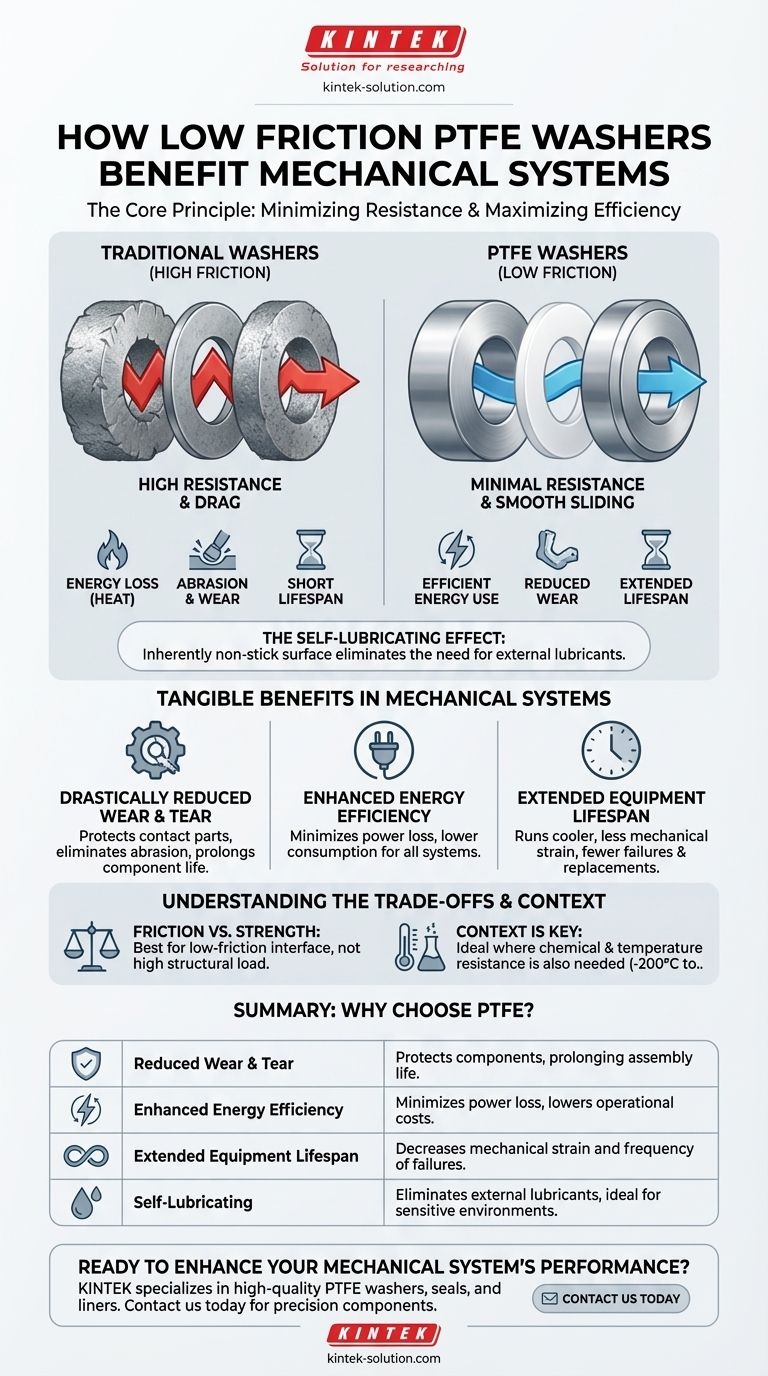

The Core Principle: Minimizing Resistance

The benefits of PTFE stem from one of its most famous material properties: an extremely low coefficient of friction. Understanding this is key to appreciating its role in mechanical design.

What is a Low Coefficient of Friction?

A low coefficient of friction means that very little force is required to move two surfaces against each other. PTFE's surface is inherently non-stick and smooth at a molecular level.

This allows components like gears or bearings to operate with minimal drag, converting more input energy into useful work instead of losing it to heat and abrasion.

The Self-Lubricating Effect

Unlike metal parts that require a film of oil or grease to operate smoothly, PTFE provides its own lubrication. This property is invaluable in many modern systems.

It is particularly critical in applications where maintenance access is difficult or where lubricants could contaminate the product, such as in food processing, pharmaceutical, or aerospace industries.

Tangible Benefits in Mechanical Systems

The theoretical advantage of low friction translates into significant, measurable improvements in real-world machinery.

Drastically Reduced Wear and Tear

The primary benefit is the protection of contact parts. When components slide smoothly, the grinding and abrasive action that wears them down over time is nearly eliminated.

This directly prolongs the life of not just the washer, but also the more expensive metal parts it interfaces with.

Enhanced Energy Efficiency

Friction is a major source of energy loss in any mechanical system. By minimizing this resistance, PTFE washers ensure that more of the system's power is used for its intended purpose.

This results in lower energy consumption, which is a critical factor for both battery-powered devices and large-scale industrial machinery.

Extended Equipment Lifespan

The combination of reduced wear and lower operational stress leads to a longer functional life for the entire assembly. Components run cooler and are subjected to less mechanical strain, decreasing the frequency of failures and costly replacements.

Understanding the Trade-offs

While its low-friction properties are exceptional, PTFE is not a universal solution. A clear-eyed assessment of its limitations is crucial for proper application.

Friction vs. Mechanical Strength

PTFE is a relatively soft material. While its low friction is a major asset, it does not possess the high compressive strength or load-bearing capacity of metals or harder polymers.

It is best used in applications where its primary role is to provide a low-friction interface, not to serve as a primary structural component under immense load.

The Importance of Context

The true power of PTFE often comes from its combination of properties. It is not just low-friction; it is also highly resistant to chemicals and extreme temperatures (from -200°C to +260°C).

The decision to use PTFE is strongest when a system demands low friction in addition to resilience against corrosive substances or wide temperature fluctuations.

Making the Right Choice for Your System

Selecting the right material is about matching its properties to your primary goal.

- If your primary focus is longevity and reduced maintenance: PTFE washers minimize wear on critical moving parts, directly extending service intervals and the life of your equipment.

- If your primary focus is energy efficiency: The low-friction surface reduces wasted energy, making it ideal for continuous-motion systems where every watt counts.

- If your primary focus is operational purity: PTFE's self-lubricating nature is essential for food, medical, or pharmaceutical applications where contamination is not an option.

Ultimately, leveraging the low friction of PTFE is a strategic choice for creating more efficient, reliable, and durable mechanical systems.

Summary Table:

| Benefit | Impact on Mechanical Systems |

|---|---|

| Reduced Wear & Tear | Protects components, prolonging the life of the entire assembly. |

| Enhanced Energy Efficiency | Minimizes power loss to friction, lowering operational costs. |

| Extended Equipment Lifespan | Decreases mechanical strain and frequency of failures. |

| Self-Lubricating | Eliminates need for external lubricants, ideal for contamination-sensitive environments. |

Ready to enhance your mechanical system's performance with precision PTFE components?

KINTEK specializes in manufacturing high-quality PTFE washers, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver superior low-friction performance, reduce maintenance, and boost efficiency.

Contact us today to discuss your project and discover how our PTFE solutions can benefit your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What materials are used in spring energized Teflon seals? A Guide to PTFE Jackets & Metal Springs

- What are the temperature resistance capabilities of PTFE with fillers? Select the Right High-Performance Material

- What pressure considerations apply to PTFE lined butterfly valves? Avoid Liner Failure and Ensure Safe Operation

- What are the limitations of PTFE O-rings' media resistance? Avoid Common Application Traps

- What are the basic shapes of molded PTFE materials available? A Guide to Stock Forms & Machining

- How is PTFE utilized in food processing lines? Enhance Safety, Efficiency & Equipment Lifespan

- What are the torque requirements for PTFE gaskets according to EN 1591-1? A Guide to Reliable Sealing

- What precautions should be taken for maximum seal life expectancy? Follow the 75% Rule for Longevity