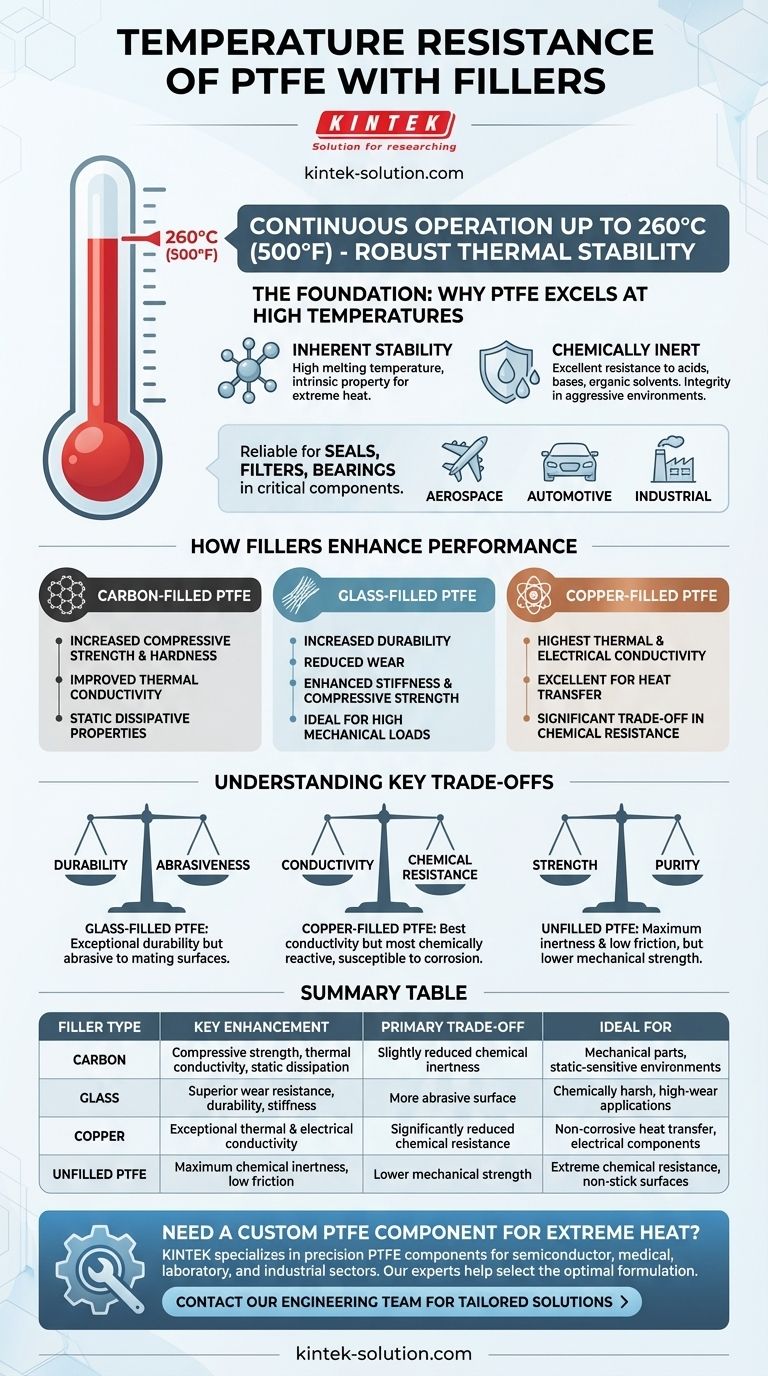

In short, filled PTFE can operate continuously at temperatures up to 260°C (500°F). This robust thermal stability is a hallmark of Polytetrafluoroethylene, but the addition of fillers is what transforms it from a simple non-stick material into a high-performance engineering component designed for specific, demanding applications.

The key takeaway is not just the temperature rating, but understanding how different fillers modify PTFE's properties. Choosing the right filled PTFE requires balancing its excellent heat resistance against the specific enhancements—and trade-offs—introduced by the filler material.

The Foundation: Why PTFE Excels at High Temperatures

The Inherent Stability of PTFE

Polytetrafluoroethylene (PTFE) is a fluoropolymer with an exceptionally high melting temperature compared to most conventional plastics. This intrinsic property is the foundation of its performance in extreme heat.

It is also a chemically inert material, giving it excellent resistance to most acids, bases, and organic solvents. This allows it to maintain its integrity not just at high temperatures, but also in aggressive chemical environments.

The Role of Temperature in Applications

The ability to operate reliably up to 260°C (500°F) makes filled PTFE suitable for critical components like seals, filters, and bearings in aerospace, automotive, and industrial processing. Materials used in these contexts must not degrade or lose their structural integrity when exposed to constant heat.

How Fillers Enhance PTFE Performance

The Purpose of Adding Fillers

While pure PTFE has excellent temperature and chemical resistance, it can be mechanically soft. Fillers are added to enhance specific physical properties like compressive strength, durability, and thermal or electrical conductivity, tailoring the material for a specific task.

Carbon-Filled PTFE

Adding carbon as a filler significantly increases compressive strength and hardness. It also improves thermal conductivity, allowing heat to dissipate more effectively, and provides static dissipative properties.

Glass-Filled PTFE

Glass is a common filler used to increase durability and reduce wear. Glass-filled PTFE exhibits enhanced stiffness and compressive strength, making it ideal for components that experience high mechanical loads.

Copper-Filled PTFE

For applications requiring the highest thermal and electrical conductivity, copper (or bronze) is added. This makes the material excellent for heat transfer applications, but it comes with a significant trade-off in chemical resistance.

Understanding the Key Trade-offs

Durability vs. Abrasiveness

While glass-filled PTFE offers exceptional durability, its surface is more abrasive than other formulations. This can cause wear on softer, mating surfaces over time, a critical consideration in dynamic seal or bearing applications.

Conductivity vs. Chemical Resistance

This is the most critical trade-off. Copper-filled PTFE provides the best conductivity but is also the most chemically reactive of the common formulations. It is susceptible to corrosion and should not be used with aggressive chemicals, liquid alkali metals, or certain fluorine compounds where pure or glass-filled PTFE would excel.

Strength vs. Purity

Adding any filler alters the pure, inert nature of PTFE. If your primary needs are extreme chemical inertness and a low coefficient of friction ("non-stick"), and mechanical strength is less of a concern, then unfilled PTFE may still be the superior choice.

Making the Right Choice for Your Goal

Selecting the correct material requires a clear understanding of your primary operational demand.

- If your primary focus is mechanical strength and static dissipation: Carbon-filled PTFE provides an excellent balance of enhanced physical properties and good chemical resistance.

- If your primary focus is maximum durability in chemically harsh environments: Glass-filled PTFE offers superior wear resistance, but you must account for its abrasive nature.

- If your primary focus is exceptional thermal or electrical conductivity: Copper-filled PTFE is the leader, but it must be restricted to non-corrosive environments.

By understanding these trade-offs, you can select the precise PTFE formulation that delivers optimal performance under your specific operating conditions.

Summary Table:

| Filler Type | Key Enhancement | Primary Trade-off | Ideal For |

|---|---|---|---|

| Carbon | Increased compressive strength, thermal conductivity, static dissipation | Slightly reduced chemical inertness | Mechanical parts, static-sensitive environments |

| Glass | Superior wear resistance, durability, stiffness | More abrasive surface | Chemically harsh, high-wear applications |

| Copper | Exceptional thermal & electrical conductivity | Significantly reduced chemical resistance | Non-corrosive heat transfer, electrical components |

| Unfilled PTFE | Maximum chemical inertness, low friction | Lower mechanical strength | Extreme chemical resistance, non-stick surfaces |

Need a custom PTFE component that performs reliably under extreme heat and specific operational demands?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between temperature resistance, mechanical strength, and chemical compatibility.

Our experts will help you select the optimal filled or unfilled PTFE formulation and provide custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for performance and durability.

Contact our engineering team today to discuss your application requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability