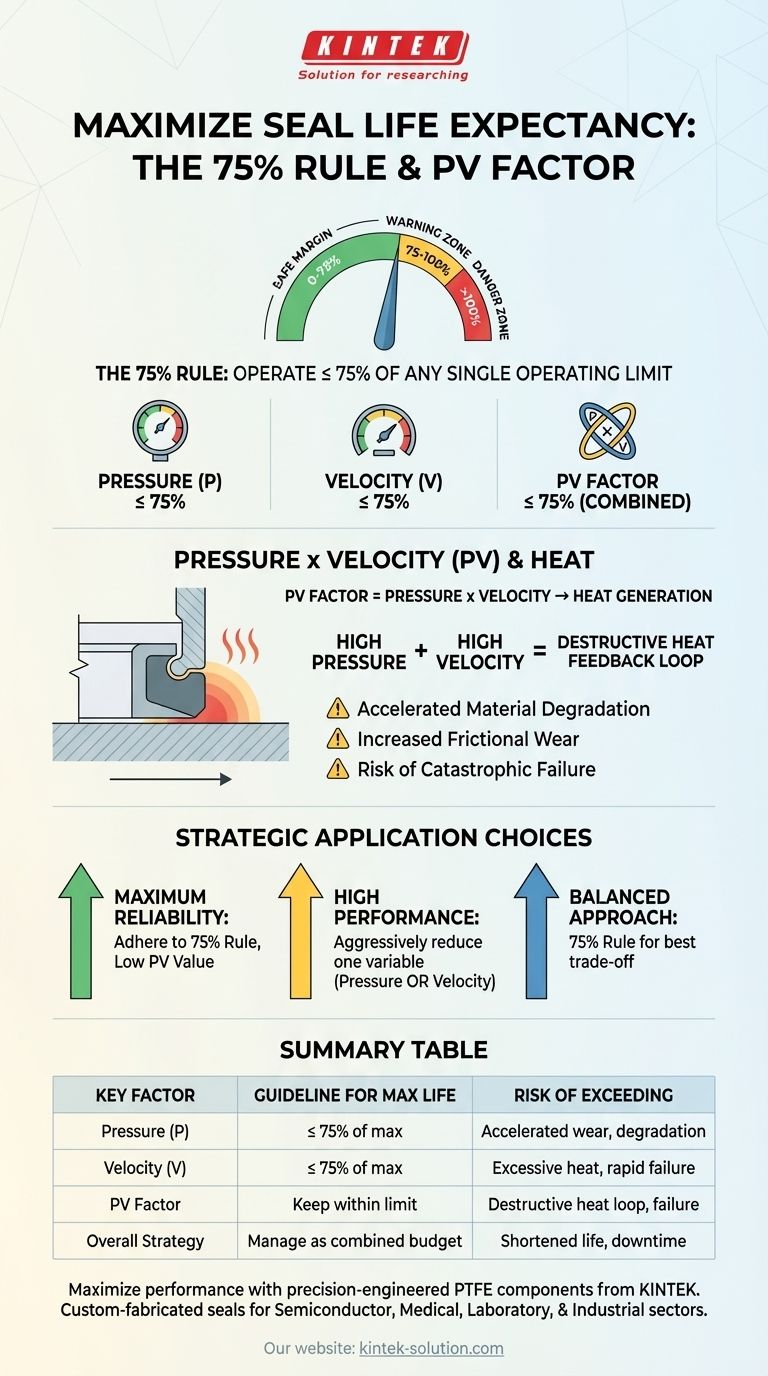

To achieve maximum seal life expectancy, you must operate with a significant safety margin. This means never exceeding 75% of any single operating limit, such as pressure or speed. Crucially, you cannot operate at the upper end of both the pressure and speed ratings simultaneously, as their combined effect is the primary driver of seal wear and failure.

The core principle for extending seal life is derating. A seal's published limits for pressure and speed are not independent targets; they are competing constraints. Longevity is achieved not by staying under individual maximums, but by managing the combined operational stress, primarily the heat generated by pressure and velocity.

Why Published Limits Aren't the Full Story

Manufacturer ratings often represent the absolute maximum a seal can withstand for a single variable under ideal laboratory conditions. In the real world, multiple forces are acting on the seal at once, creating a more demanding environment than any single rating can describe.

Understanding the "75% Rule" of Derating

Derating is the practice of intentionally operating a component well below its rated maximum capabilities to ensure reliability.

The 75% rule is a widely accepted guideline for this practice. By limiting operation to 75% of any single limit, you build a critical safety buffer. This margin accounts for unexpected system spikes, material fatigue over time, and variations in lubrication or temperature.

The Critical Relationship: Pressure and Velocity (PV)

The most common cause of premature seal failure is excessive heat. This heat is generated primarily by the friction between the seal and the moving surface.

The amount of frictional heat generated is a direct product of Pressure (P) and Velocity (V). This relationship is often expressed as the PV factor, a key metric for seal performance.

Operating at high pressure and high velocity creates a destructive feedback loop. The combination generates extreme heat, which breaks down the seal material, reduces lubrication effectiveness, and leads to rapid failure. This is why you cannot operate at the maximums for both simultaneously.

Understanding the Trade-offs and Risks

Pushing a seal to its absolute limits is a decision with significant consequences. It exchanges short-term performance for long-term reliability and creates unnecessary risk.

Accelerated Material Degradation

Excessive heat from a high PV value chemically degrades the seal material, typically an elastomer. The material may become hard and brittle, losing its ability to conform to surfaces and maintain a proper seal. This leads to leaks and eventual cracking.

Increased Frictional Wear

Higher pressure forces the seal lip harder against the moving surface, while higher velocity increases the distance it travels in a given time. Together, they physically abrade the seal material at an accelerated rate, shortening its operational life even if the material doesn't overheat.

Risk of Catastrophic Failure

Operating near the maximum PV limit doesn't just reduce lifespan; it dramatically increases the chance of a sudden, complete failure. This can cause major fluid leaks, damage to other system components, and costly unplanned downtime.

Making the Right Choice for Your Application

Your operational strategy should be dictated by the goals of your specific application. Use the seal's limits not as targets, but as a guide to define a safe and reliable operating window.

- If your primary focus is maximum reliability and longevity: Strictly adhere to the 75% rule and calculate your application's PV value to ensure it is well within the manufacturer's specified PV limit.

- If your primary focus is high performance (approaching one limit): You must aggressively reduce the other variables. To run at high speed, system pressure must be kept low. To contain high pressure, surface speed must be minimized.

- If your primary focus is balancing performance and lifespan: The 75% rule provides the best framework. This conservative approach is the most effective strategy for preventing premature failures and maximizing the return on your investment.

Ultimately, treating a seal's operating limits as a combined budget—rather than individual allowances—is the key to ensuring long-term, trouble-free service.

Summary Table:

| Key Factor | Guideline for Maximum Life | Risk of Exceeding |

|---|---|---|

| Pressure (P) | Operate ≤ 75% of max rated pressure | Accelerated wear, material degradation |

| Velocity (V) | Operate ≤ 75% of max rated speed | Excessive frictional heat, rapid failure |

| PV Factor | Keep combined PV value well within limit | Destructive heat feedback loop, catastrophic failure |

| Overall Strategy | Manage pressure and speed as a combined budget, not independent targets | Shortened lifespan, unplanned downtime |

Maximize your seal's performance and lifespan with precision-engineered PTFE components from KINTEK.

Understanding the delicate balance between pressure, speed, and heat is critical for reliability. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware are manufactured with the precision needed to perform consistently within safe operating windows.

We help you avoid premature failure and costly downtime. From prototypes to high-volume orders, KINTEK delivers the quality and expertise your application demands.

Contact KINTEK today to discuss your specific requirements and ensure long-term, trouble-free service from your critical components.

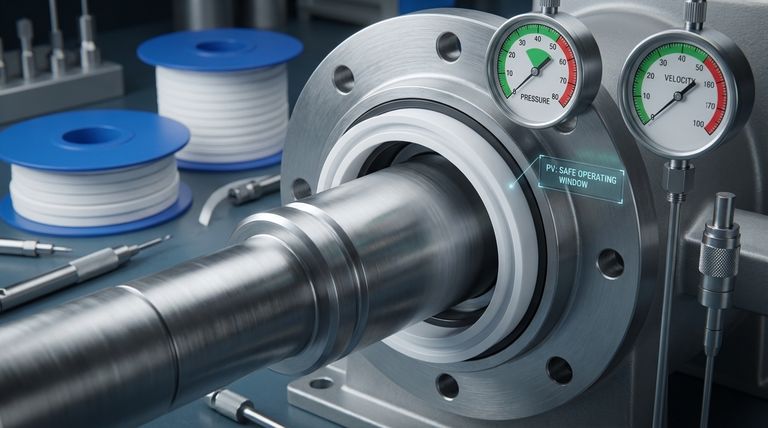

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of PTFE bellows are available and their specific uses? A Guide to Round, Angular, and Sharp Fold Designs

- Why are PTFE washers advantageous in mechanical assemblies? Enhance Performance & Durability

- What are the installation benefits of PTFE compensators compared to metal alternatives? Achieve Faster, Safer, and More Cost-Effective Installation

- How should thin-wall PTFE components be clamped during machining? Prevent Deformation with the Right Fixtures

- What cooling and lubrication techniques are recommended for PTFE machining? Master Heat Control for Precision Parts

- What are the core materials used in TFE Encapsulated gaskets and their applications? A Guide to Superior Sealing

- What are the benefits of white TFE Encapsulated silicone core gaskets? Optimize Purity & Performance

- What are the advantages of PTFE Liner in terms of weight and noise reduction? Achieve Quieter, Lighter Systems