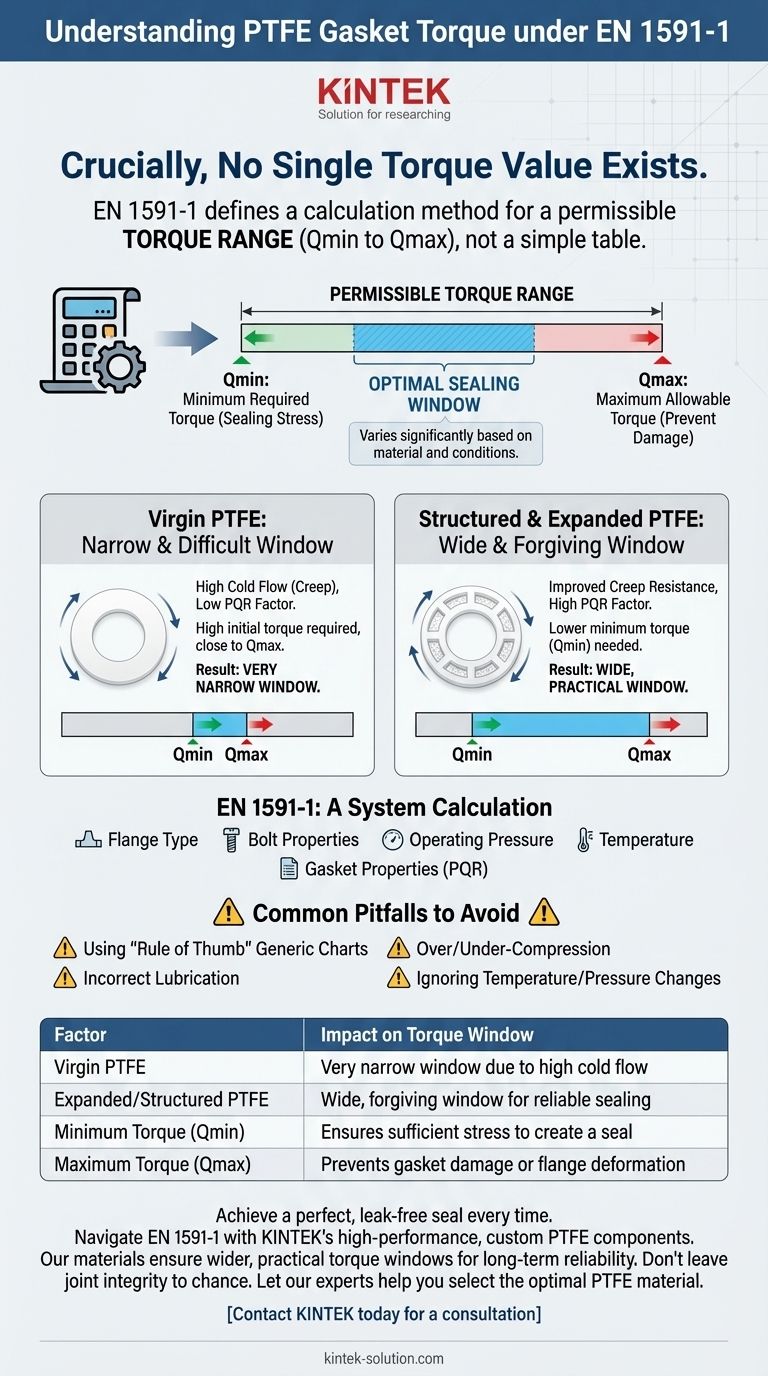

Crucially, there is no single torque value. The European standard EN 1591-1 does not provide a simple lookup table for PTFE gasket torque. Instead, it defines a sophisticated calculation method used to determine a specific, permissible torque range—from a minimum required value to a maximum allowable value—for your exact application. This range is highly dependent on the type of PTFE being used.

The core principle of EN 1591-1 is that achieving a reliable, long-term seal is not about hitting one magic number. It's about applying a bolt load that is high enough to create a seal (Qmin) but low enough to avoid damaging the gasket or flange (Qmax), a window that changes dramatically based on your specific material and operating conditions.

Why EN 1591-1 Is a Calculation, Not a Table

The standard treats a bolted flange joint as an entire mechanical system. The calculation aims to ensure the gasket is loaded correctly throughout its service life, accounting for all variables that can lead to failure.

The Minimum Required Torque (Qmin)

This is the lower bound of your target range. It represents the torque needed to apply enough compressive stress on the gasket to conform to the flange surfaces and achieve the required level of tightness for the specified operating pressure.

The Maximum Allowable Torque (Qmax)

This is the upper bound. Exceeding this torque risks physically damaging the gasket through over-compression or, in extreme cases, yielding the bolts or deforming the flange faces.

The Critical Role of PTFE Material Properties

Not all PTFE is created equal. The mechanical properties of the specific gasket material are one of the most important inputs for the EN 1591-1 calculation, directly influencing the width of the acceptable torque window.

Virgin PTFE: The Challenge of Cold Flow

Virgin, or unfilled, PTFE is known for its exceptional chemical resistance but poor mechanical properties. It is highly susceptible to cold flow (also known as creep or relaxation), where the material deforms and flows away from the compressive load over time.

This characteristic is represented by a low PQR factor in the EN 1591-1 calculation. A low PQR signifies high stress relaxation, meaning the initial sealing stress drops significantly after installation. To compensate, a very high initial torque is required, pushing the minimum value (Qmin) uncomfortably close to the maximum limit (Qmax). This results in a very narrow and difficult-to-achieve torque window.

Structured & Expanded PTFE: A Wider Margin for Success

To overcome the limitations of virgin PTFE, manufacturers modify its structure (e.g., expanded ePTFE) or add fillers (e.g., silica, glass). These enhancements dramatically improve creep resistance.

This results in a much higher PQR factor. The improved mechanical stability means the gasket retains its sealing stress far more effectively. Consequently, the minimum required torque (Qmin) is lower, creating a wide, practical, and forgiving torque window that makes successful installation far more likely.

Common Pitfalls to Avoid

Relying on outdated practices or generic data is the primary cause of gasket failure. The EN 1591-1 approach is designed to prevent these very issues.

The Danger of "Rule of Thumb" Torquing

Using generic torque charts that do not account for your specific operating pressure, temperature, media, and gasket material properties is a recipe for failure. These charts cannot possibly replicate the precision of an EN 1591-1 calculation.

Over-Compression vs. Under-Compression

The outcome of missing the calculated torque window is predictable. Torquing below Qmin results in insufficient gasket stress and an inevitable leak. Torquing above Qmax permanently damages the gasket's internal structure, compromising its ability to seal and potentially requiring a complete replacement.

The Impact of Lubrication

The EN 1591-1 calculation accounts for the friction factor between the bolt threads and the nut. Using a different lubricant than specified—or no lubricant at all—will drastically alter the bolt load achieved for a given torque value, invalidating the calculation.

Making the Right Choice for Your Application

To ensure the integrity of your bolted flange joint, your approach must be guided by the demands of the system.

- If your primary focus is maximum chemical compatibility in a low-stress application: Virgin PTFE may be an option, but you must perform a precise EN 1591-1 calculation and recognize the extremely narrow and unforgiving torque window.

- If your primary focus is reliability, ease of installation, and joint integrity: Always choose a high-quality structured or expanded PTFE gasket and use software or an engineering provider to perform a proper EN 1591-1 calculation.

Ultimately, ensuring a safe and reliable seal depends on treating the joint as an engineered system, not just a set of parts.

Summary Table:

| Factor | Impact on Torque Window |

|---|---|

| Virgin PTFE | Very narrow window due to high cold flow |

| Expanded/Structured PTFE | Wide, forgiving window for reliable sealing |

| Minimum Torque (Qmin) | Ensures sufficient stress to create a seal |

| Maximum Torque (Qmax) | Prevents gasket damage or flange deformation |

Achieve a perfect, leak-free seal every time.

Navigating EN 1591-1 torque calculations can be complex, but the right PTFE gasket material is the foundation of success. At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals and gaskets—for the semiconductor, medical, laboratory, and industrial sectors.

Our expanded and filled PTFE materials are engineered for superior creep resistance, providing a wider, more practical torque window for easier installation and long-term reliability. Whether you need prototypes or high-volume orders, our precision production ensures your gaskets meet the exact demands of your application.

Don't leave your joint integrity to chance. Let our experts help you select the optimal PTFE material and ensure your sealing solution is calculated for success.

Contact KINTEB today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments