In short, there are two primary pressure considerations for PTFE lined butterfly valves: you must avoid excessive pressure differentials that can rupture the liner, and critically, you must prevent any negative pressure (vacuum) which can cause the liner to collapse or detach from the valve body. These factors are heavily influenced by the system's operating temperature.

The core principle to understand is that the PTFE liner provides excellent chemical resistance but has limited structural strength. Its integrity depends on maintaining a delicate balance between pressure and temperature to prevent mechanical failure.

The Role of the PTFE Liner

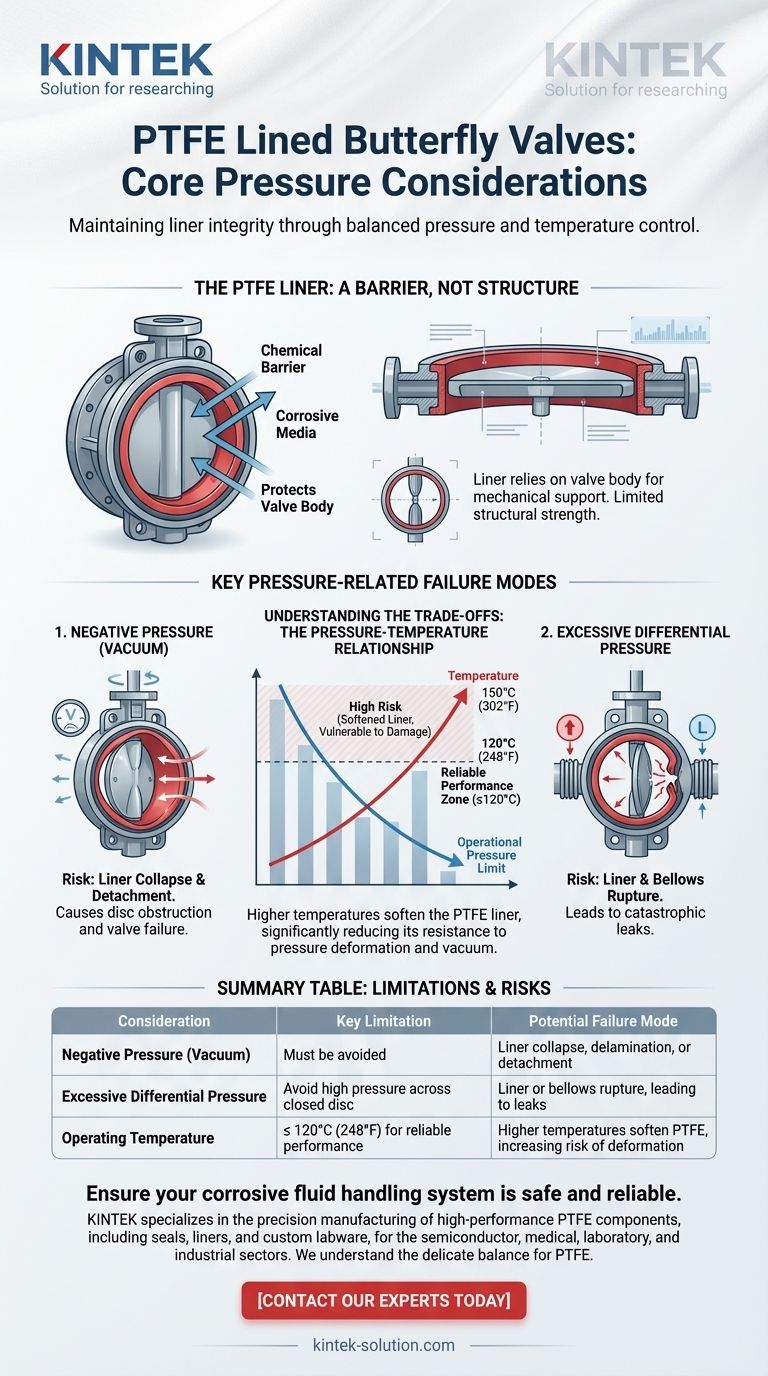

A Barrier, Not a Structure

PTFE lined butterfly valves are selected for their exceptional ability to handle highly corrosive media. The PTFE liner acts as an inert barrier, protecting the valve's metal body from chemical attack.

This design leverages the chemical resistance of PTFE, but it's crucial to remember the liner is not a structural component. It relies on the valve body for mechanical support.

Understanding its Mechanical Limits

PTFE is a fluoropolymer with a low coefficient of friction, which aids in smooth valve operation. However, it is also a relatively soft material that can deform under stress.

Its mechanical properties, particularly its rigidity and tensile strength, change significantly with temperature.

Key Pressure-Related Failure Modes

The Danger of Negative Pressure (Vacuum)

This is the most critical and often overlooked pressure consideration for lined valves. A vacuum condition inside the pipeline can create a suction effect.

This negative pressure can pull the PTFE liner away from the inner wall of the valve body, causing it to bulge, delaminate, or collapse.

A collapsed liner will obstruct the valve disc, leading to malfunction, improper sealing, and complete valve failure.

The Impact of Excessive Differential Pressure

A high pressure difference across the closed valve disc places significant stress on the liner and its seals.

While the valve body is designed for pressure, the liner itself can be compromised. In designs that use PTFE bellows for sealing, this excessive pressure can directly cause the bellows to rupture, leading to a catastrophic leak.

Understanding the Trade-offs: The Pressure-Temperature Relationship

The operational pressure a PTFE lined valve can handle is not a fixed number; it is inversely related to the operating temperature.

How Heat Softens the Liner

As the temperature of the media increases, the PTFE liner begins to soften and lose its rigidity.

A softer liner is far more susceptible to mechanical damage. It can be more easily deformed by pressure or pulled away from the valve body by a vacuum.

Defining Operational Temperature Limits

For reliable, long-term performance, the media temperature for a PTFE lined butterfly valve should be controlled at or below 120°C (248°F).

The valve may tolerate short-term spikes up to 150°C (302°F), but sustained operation at this level will accelerate liner degradation and significantly increase the risk of failure.

Making the Right Choice for Your System

To ensure the reliability and safety of your process, you must evaluate your system's conditions against the valve's limitations.

- If your primary focus is reliability in a high-corrosion environment: Ensure your system has robust controls to prevent both over-pressure and any chance of vacuum formation.

- If your primary focus is operating near the upper temperature limit: You must implement even stricter pressure controls, as the liner's resistance to deformation will be significantly reduced.

- If your system is prone to vacuum conditions: A standard PTFE lined butterfly valve is likely the wrong choice; you should investigate alternative valve types or liner designs specifically rated for vacuum service.

Ultimately, treating the PTFE liner as a high-performance shield, not structural armor, is the key to its successful application.

Summary Table:

| Consideration | Key Limitation | Potential Failure Mode |

|---|---|---|

| Negative Pressure (Vacuum) | Must be avoided | Liner collapse, delamination, or detachment from valve body |

| Excessive Differential Pressure | Avoid high pressure across closed disc | Liner or PTFE bellows rupture, leading to leaks |

| Operating Temperature | ≤ 120°C (248°F) for reliable performance | Higher temperatures soften PTFE, increasing risk of deformation |

Ensure your corrosive fluid handling system is safe and reliable.

The pressure and temperature limits of your PTFE lined components are critical to your operation's success and safety. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware, for the semiconductor, medical, laboratory, and industrial sectors.

We understand the delicate balance required for PTFE to perform optimally. Let us provide you with components that meet your exact specifications, from prototypes to high-volume orders, ensuring durability and chemical resistance.

Contact our experts today to discuss your application requirements and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability