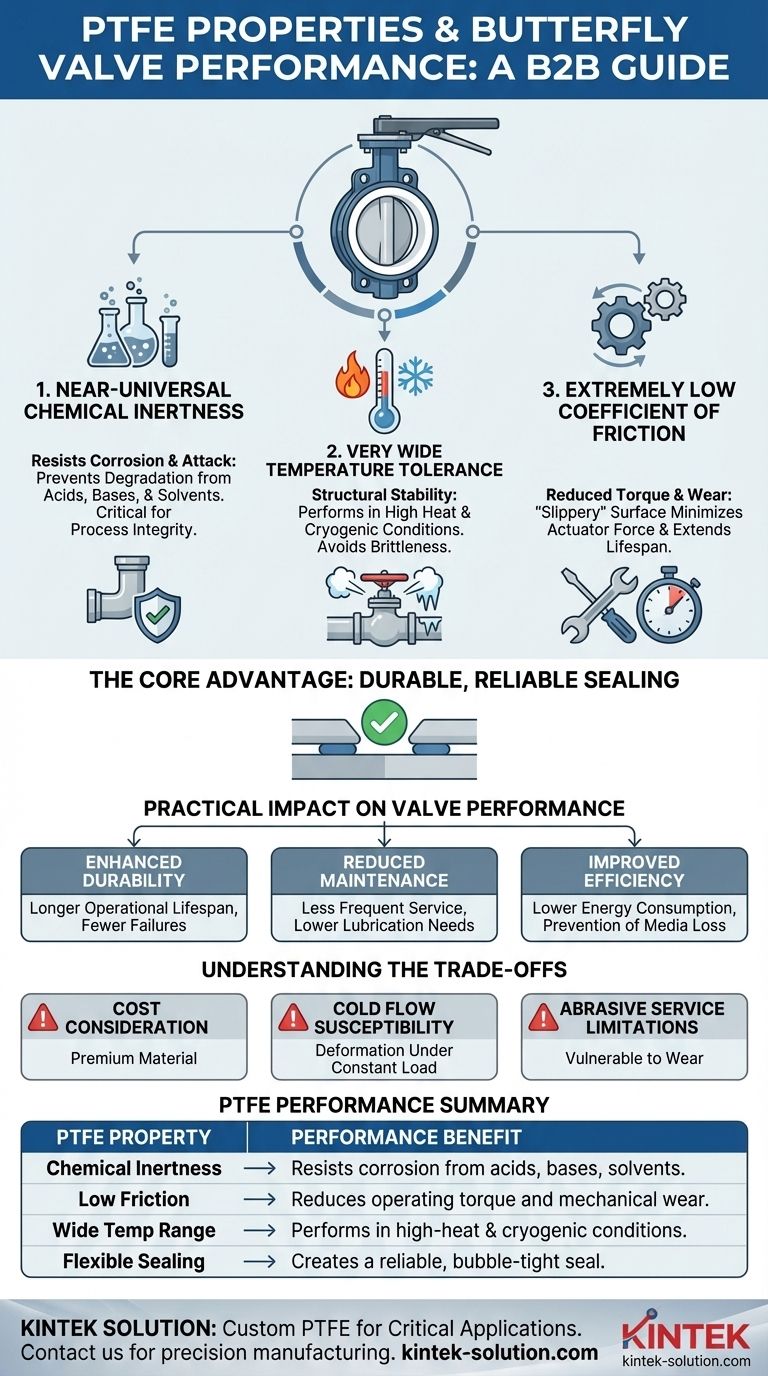

At its core, Polytetrafluoroethylene (PTFE) significantly enhances butterfly valve performance through a unique combination of three key properties: near-universal chemical inertness, a very wide temperature tolerance, and an extremely low coefficient of friction. These characteristics create a highly durable and reliable seal, ensuring the valve operates effectively and has a long service life, especially in demanding industrial environments.

The choice of PTFE for a butterfly valve seat is not merely a material specification; it is a strategic decision to enhance operational reliability, reduce maintenance overhead, and ensure safety when handling corrosive or high-temperature media.

Deconstructing PTFE's Core Advantages

To understand why PTFE is a superior material for many butterfly valve applications, we must examine how its fundamental properties translate into tangible performance benefits.

Unmatched Chemical Inertness

PTFE is renowned for being non-reactive. It is resistant to corrosion and chemical attack from a vast range of aggressive substances, including strong acids, bases, and solvents.

This inertness prevents the valve seat from degrading, swelling, or failing when it comes in contact with process media, which is critical in industries like chemical processing and pharmaceuticals.

Superior Temperature Stability

PTFE maintains its structural integrity and performance characteristics across an exceptionally broad temperature range.

This thermal stability makes it suitable for both high-temperature services, such as in petrochemical plants, and extremely cold or cryogenic applications where other elastomers would become brittle and fail.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This "slippery" characteristic directly reduces the torque required to open and close the valve. Lower torque allows for the use of smaller, less expensive actuators and dramatically minimizes wear and tear on the valve seat and disc during operation.

Reliable, Bubble-Tight Sealing

The inherent flexibility of PTFE allows it to conform to the valve disc, creating a "bubble-tight" seal that effectively prevents leaks.

This reliable sealing capability is crucial for process efficiency, environmental protection, and personnel safety, ensuring that the process fluid remains contained.

The Practical Impact on Valve Performance

These material properties are not just theoretical; they have a direct and measurable impact on the day-to-day operation and long-term cost of ownership for a butterfly valve.

Enhanced Durability and Longevity

The combination of chemical resistance and low friction means the valve's core components are protected from both chemical degradation and mechanical wear. This directly translates to a longer operational lifespan and fewer failures.

Reduced Maintenance Requirements

A valve with a robust PTFE seat requires less frequent attention. The material's durability means seals and gaskets last longer, and its low-friction nature reduces the need for frequent lubrication of internal moving parts, simplifying maintenance schedules.

Improved Operational Efficiency

Lower actuation torque means less energy is consumed to operate the valve, especially in automated systems. Furthermore, the reliable, leak-free seal prevents the loss of valuable process media, contributing to a more efficient and profitable operation.

Understanding the Trade-offs

While PTFE offers exceptional performance, no material is perfect for every situation. An objective assessment requires acknowledging its limitations.

Cost Consideration

PTFE is a premium performance polymer. Its upfront material cost is typically higher than that of standard elastomers like EPDM. The investment is justified by its performance in harsh conditions where other materials would fail quickly.

Susceptibility to Cold Flow

Under high, constant pressure (a condition known as "static load"), PTFE can be susceptible to "cold flow" or creep. This means the material can slowly deform over time, potentially compromising the seal. This is often mitigated by using "filled PTFE," which blends PTFE with other materials to enhance its rigidity.

Limitations in Abrasive Service

While highly durable against chemical and frictional wear, pure PTFE can be worn down by highly abrasive media like industrial slurries. In these specific applications, alternative seat materials or specially formulated valve designs may be more appropriate.

Making the Right Choice for Your Goal

Selecting the correct valve seat material depends entirely on the demands of your specific application.

- If your primary focus is handling aggressive chemicals: PTFE is the definitive choice due to its near-universal chemical inertness.

- If your primary focus is high-temperature processes: PTFE's thermal stability makes it the superior option over standard elastomers that would degrade.

- If your primary focus is general water or steam service: A more cost-effective elastomer like EPDM may be sufficient if the extreme properties of PTFE are not required.

- If your primary focus is maximizing longevity and minimizing operational torque: PTFE's exceptionally low friction directly reduces wear and lowers actuator energy requirements.

Understanding these material properties empowers you to select a valve that ensures safety, reliability, and outstanding long-term value for your system.

Summary Table:

| PTFE Property | Performance Benefit |

|---|---|

| Chemical Inertness | Resists corrosion from acids, bases, and solvents |

| Low Friction | Reduces operating torque and mechanical wear |

| Wide Temperature Range | Performs in both high-heat and cryogenic conditions |

| Flexible Sealing | Creates a reliable, bubble-tight seal |

Need a high-performance PTFE component for your critical application?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and custom labware. Whether you require a prototype or a high-volume order for the semiconductor, medical, or industrial sectors, our expertise ensures a component that delivers superior chemical resistance, thermal stability, and longevity.

Contact our engineering team today to discuss how our custom PTFE solutions can enhance the reliability and efficiency of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE applied in electronics and semiconductor manufacturing? Ensure Purity and Performance

- What shapes and forms are PTFE washers available in? From Standard Circles to Custom Profiles

- Why are Teflon bellow mechanical seals suitable for pulp and paper manufacturing?

- What are the mechanical properties of PTFE balls? Leverage Low Friction & Chemical Resistance

- What is the significance of the creep relaxation rate in PTFE gaskets? Ensure Long-Term Sealing Reliability

- What are the automotive applications of Teflon coating? Boost Performance and Durability

- Why are pressure conditions important when choosing PTFE packing? Ensure a Reliable Seal for Your System

- How do PTFE and NBR oil seals compare in terms of friction and wear? Choose the Right Seal for Your Application