In electronics and semiconductor manufacturing, Polytetrafluoroethylene (PTFE) is a critical material used for high-purity components, exceptional electrical insulation, and low-friction mechanical parts. Its primary applications include insulating high-frequency cables and circuit boards, coating equipment to prevent chemical contamination, and serving as wear-resistant pads and rails in cleanroom machinery.

The core reason PTFE is indispensable in these industries is its unique combination of properties: it is almost completely chemically inert, an outstanding electrical insulator, and possesses an extremely low coefficient of friction, all of which are essential for maintaining the purity and precision required to produce modern electronics.

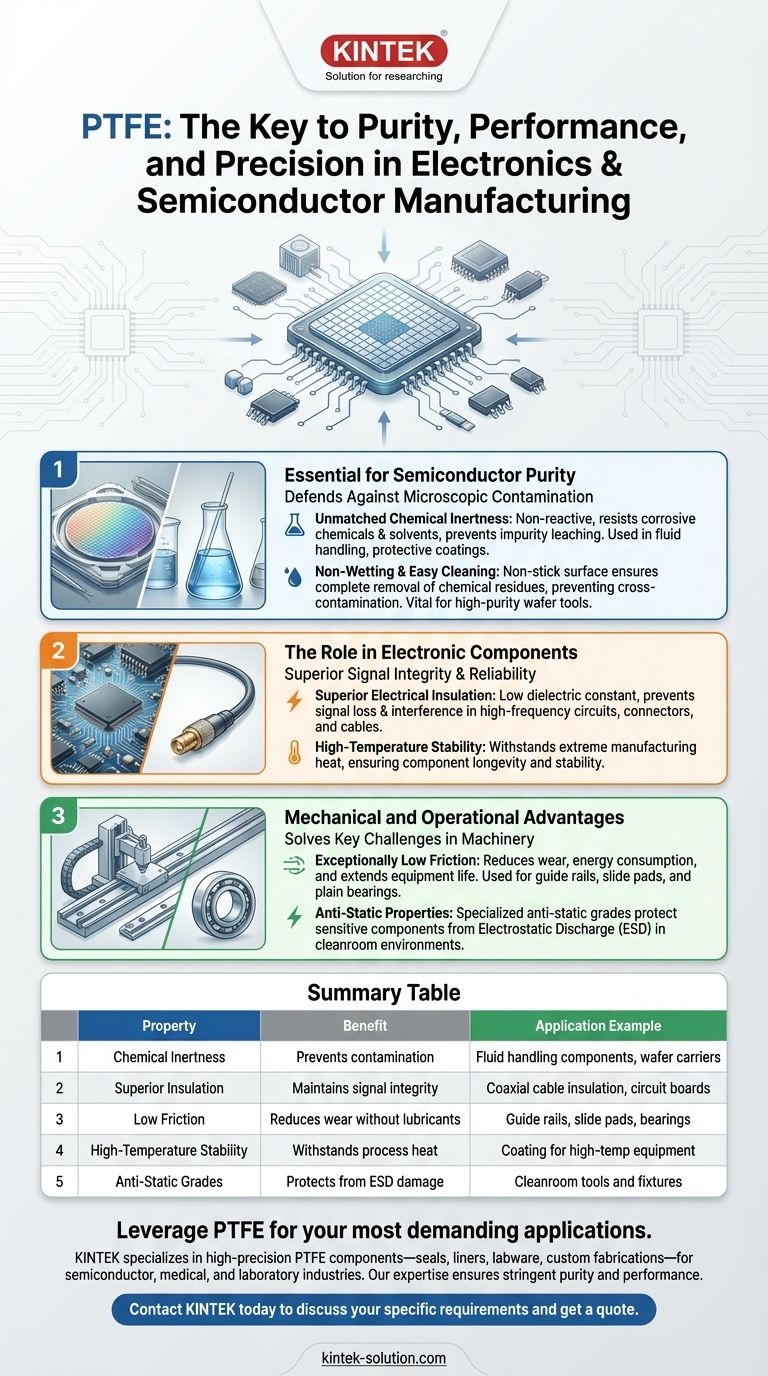

Why PTFE is Essential for Semiconductor Purity

In semiconductor fabrication, even microscopic contamination can ruin entire batches of microchips. PTFE's properties provide a powerful defense against this constant threat.

Unmatched Chemical Inertness

PTFE is non-reactive and resists virtually all corrosive industrial chemicals and solvents. This makes it the ideal material for components that handle aggressive substances during chip production, ensuring no impurities leach into the process. It remains chemically stable even when exposed to manufacturing plasmas.

Non-Wetting for Contaminant Removal

The material’s non-wetting and non-stick surface means that chemical residues can be removed easily and completely. This high-purity characteristic is vital for preventing cross-contamination between process steps.

Custom Labware and Tools

Because of its inertness, PTFE is frequently used to create custom labware essential for research and production. This includes items like wafer dippers and containers that directly contact sensitive semiconductor wafers without contaminating them.

The Role of PTFE in Electronic Components

PTFE’s electrical and thermal properties make it a superior choice for high-performance electronics where signal integrity and reliability are paramount.

Superior Electrical Insulation

PTFE has an exceptionally low dielectric constant, which means it is a highly effective electrical insulator. This property is crucial for insulating circuit boards, connectors, and high-frequency coaxial cables, preventing signal loss and interference.

High-Temperature Stability

The manufacturing of electronic components often involves high temperatures. PTFE can withstand these conditions without degrading, ensuring the stability and longevity of the parts it protects.

Design and Material Flexibility

While a natural insulator, PTFE can be modified with fillers like copper to enhance thermal or electrical conductivity. This adaptability allows engineers to tailor its properties for specific applications, such as thermal management solutions.

Mechanical and Operational Advantages

Beyond its chemical and electrical benefits, PTFE solves key mechanical challenges within manufacturing equipment.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. It is used for guide rails, low-friction slide pads, and plain bearings in automated machinery, outperforming materials like nylon or acetal. This reduces wear, lowers energy consumption, and extends equipment lifetime.

Anti-Static Properties

Static discharge can instantly destroy sensitive electronic components. PTFE is available in a specialized anti-static grade, making it an excellent choice for parts used in static-sensitive environments common in semiconductor processing.

Making the Right Choice for Your Goal

PTFE is a high-performance material chosen to solve specific engineering challenges.

- If your primary focus is preventing chemical contamination: PTFE's inertness and high purity make it the definitive choice for fluid handling systems, protective coatings, and wafer-contacting tools.

- If your primary focus is high-frequency electrical performance: Its excellent dielectric properties are ideal for building high-speed circuit boards and insulating critical wiring and cables.

- If your primary focus is reducing mechanical wear without lubricants: PTFE's low-friction surface is perfect for slide pads, bearings, and guide rails in precision cleanroom machinery.

Ultimately, understanding PTFE's core properties allows you to leverage it for creating more reliable, pure, and efficient manufacturing processes.

Summary Table:

| Property | Benefit in Electronics & Semiconductors | Application Example |

|---|---|---|

| Chemical Inertness | Prevents contamination from harsh chemicals | Fluid handling components, wafer carriers |

| Superior Insulation | Maintains signal integrity in high-frequency circuits | Coaxial cable insulation, circuit boards |

| Low Friction | Reduces wear in machinery without lubricants | Guide rails, slide pads, bearings |

| High-Temperature Stability | Withstands manufacturing process heat | Coating for high-temp equipment |

| Anti-Static Grades | Protects sensitive components from ESD damage | Cleanroom tools and fixtures |

Leverage PTFE for your most demanding applications.

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, labware, and custom fabrications—for the semiconductor, medical, and laboratory industries. Our expertise ensures your components meet the stringent purity and performance requirements critical to your success.

From prototypes to high-volume orders, we deliver the precision you need. Contact KINTEL today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials