From engine components to exterior paint, Teflon's automotive applications are extensive and engineered to solve critical challenges of friction, heat, and corrosion. It is used as a protective coating on everything from pistons and gaskets to windshield wipers and ball bearings, and also serves as an additive in specialized lubricants to enhance vehicle durability and performance.

The core reason Teflon (PTFE) is so prevalent in the automotive world is its unique combination of properties. Its extremely low friction, high heat tolerance, and chemical inertness make it a versatile material for increasing efficiency, preventing wear, and protecting components in harsh operating environments.

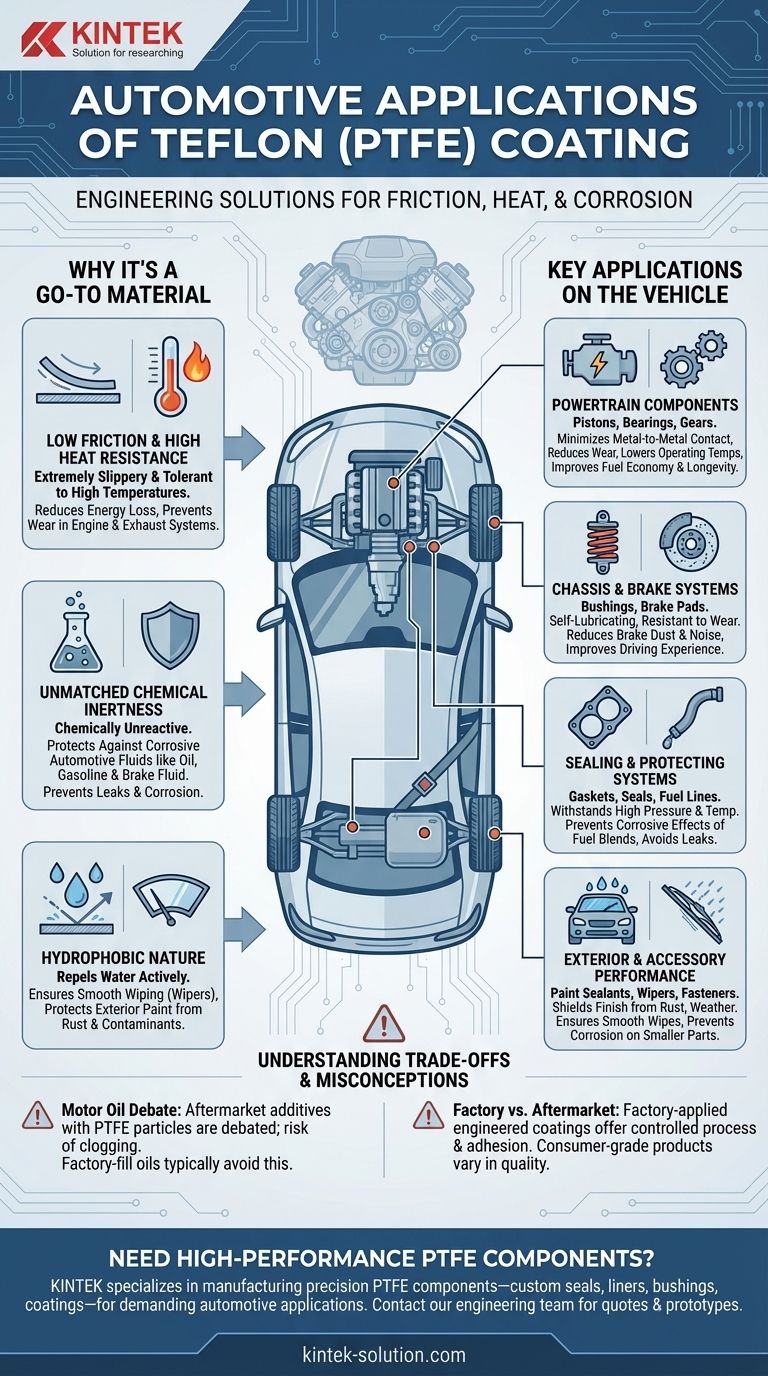

Why Teflon is a Go-To Material in Automotive Engineering

To understand its applications, you must first understand its fundamental properties. Teflon, a brand name for polytetrafluoroethylene (PTFE), is not a single-solution product but a family of fluoropolymers, each with distinct advantages.

The Core Properties: Low Friction and High Heat Resistance

The primary benefit of Teflon is its incredibly low coefficient of friction. It is one of the most slippery materials known, which is essential for reducing energy loss and wear between moving parts.

It also boasts exceptional heat resistance. This allows it to maintain its integrity and performance in high-temperature environments like engine cylinders and exhaust systems, where other materials would quickly degrade.

Unmatched Chemical and Corrosion Inertness

Automotive fluids like oil, gasoline, and brake fluid are highly corrosive. Teflon is chemically inert, meaning it does not react with these substances.

This property makes it an ideal material for gaskets, seals, and fuel hoses, preventing leaks and protecting the underlying metal from corrosion and degradation over the vehicle's lifespan.

Hydrophobic Nature for Water Repellency

Teflon is also hydrophobic, meaning it actively repels water. This is why it is used on windshield wipers to ensure a smooth, clean wipe and on exterior paint sealants to protect the finish from rain, rust, and environmental contaminants.

Key Applications on the Vehicle Itself

These core properties translate into specific, high-value applications across the vehicle, from the powertrain to the chassis.

Reducing Friction in Powertrain Components

In the engine and transmission, reducing friction is paramount for efficiency and longevity. Teflon coatings are applied to pistons, bearings, and gears.

This coating minimizes metal-to-metal contact, reducing wear and tear, lowering operating temperatures, and ultimately contributing to better fuel economy and a longer service life for the powertrain.

Enhancing Durability in Chassis and Brake Systems

The suspension and braking systems are subject to constant movement and stress. Teflon bushings are used in suspension parts and gear systems because they are self-lubricating and resistant to wear.

Coatings are also applied to components like brake pads to help reduce brake dust and noise, improving the overall driving experience.

Sealing and Protecting Critical Systems

A vehicle relies on a network of sealed systems to function. Teflon is a preferred material for gaskets and seals in engines and transmissions because it can withstand high pressure and temperature without degrading.

It is also used to line fuel lines and hoses, preventing the corrosive effects of modern fuel blends from damaging the system.

Improving Exterior and Accessory Performance

On the vehicle's exterior, Teflon is a key ingredient in high-performance paint sealants. This protective layer shields the car's finish from rust, weather, and environmental damage.

Smaller components also benefit. Windshield wipers coated with Teflon glide smoothly across the glass and repel water more effectively, while coatings on fasteners and seatbelt clips prevent corrosion and ensure reliable operation.

Understanding the Trade-offs and Misconceptions

While its benefits are clear, it's important to approach some applications with an objective, engineering-focused mindset.

The Debate Over Teflon in Motor Oil

Some aftermarket motor oil additives contain suspended PTFE particles, marketed as an internal lubricant. While the references mention this, the practice is highly debated among automotive engineers.

The concern is that these particles may not remain suspended and could potentially clog narrow oil passages, leading to oil starvation in critical engine parts. Factory-fill oils from major automakers do not use this technology.

Factory Application vs. Aftermarket Products

There is a significant difference between a factory-applied coating and an aftermarket spray or sealant.

Engineered coatings are applied in a controlled industrial process, ensuring proper adhesion and thickness for a specific purpose. The quality and longevity of consumer-grade aftermarket products can vary widely.

How to Apply This to Your Goal

Understanding where and why Teflon is used can help you make better decisions for vehicle maintenance and performance.

- If your primary focus is OEM-level performance and longevity: Trust the components engineered with factory-applied Teflon coatings, as they are designed for specific high-stress applications like pistons, bearings, and gaskets.

- If your primary focus is vehicle maintenance and protection: Consider professional-grade paint sealants and coatings that use fluoropolymers for durable, hydrophobic protection against environmental factors.

- If your primary focus is engine modification: Exercise caution with aftermarket oil additives containing PTFE; their benefits are debated, and the risk of unintended consequences exists.

Ultimately, leveraging Teflon in automotive applications is about applying its unique material science to solve specific engineering challenges, enhancing both performance and durability.

Summary Table:

| Application Area | Key Components | Key Benefit of Teflon (PTFE) |

|---|---|---|

| Powertrain | Pistons, Bearings, Gears | Reduces friction, lowers operating temperature, improves fuel economy |

| Chassis & Brakes | Bushings, Brake Pads | Self-lubricating, reduces wear, noise, and brake dust |

| Sealing Systems | Gaskets, Seals, Fuel Lines | Withstands high pressure & temperature, prevents corrosion and leaks |

| Exterior & Accessories | Paint Sealants, Windshield Wipers | Repels water, protects against rust and environmental damage |

Need high-performance PTFE components for your automotive applications?

KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, bushings, and coatings—for the automotive industry and other demanding sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get durable, reliable parts that enhance performance and longevity.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers