When selecting an oil seal, the material's inherent friction and wear characteristics are paramount. Polytetrafluoroethylene (PTFE) seals offer exceptionally low friction and are self-lubricating, making them highly resistant to wear even in dry or low-oil conditions. In contrast, Nitrile Butadiene Rubber (NBR) seals have moderate friction and depend entirely on a consistent lubricant film to minimize wear and prevent premature failure.

The choice between PTFE and NBR is a strategic decision that goes beyond simple friction values. It involves balancing the superior wear resistance and operational flexibility of PTFE against the cost-effective, proven reliability of NBR in standard, well-lubricated environments.

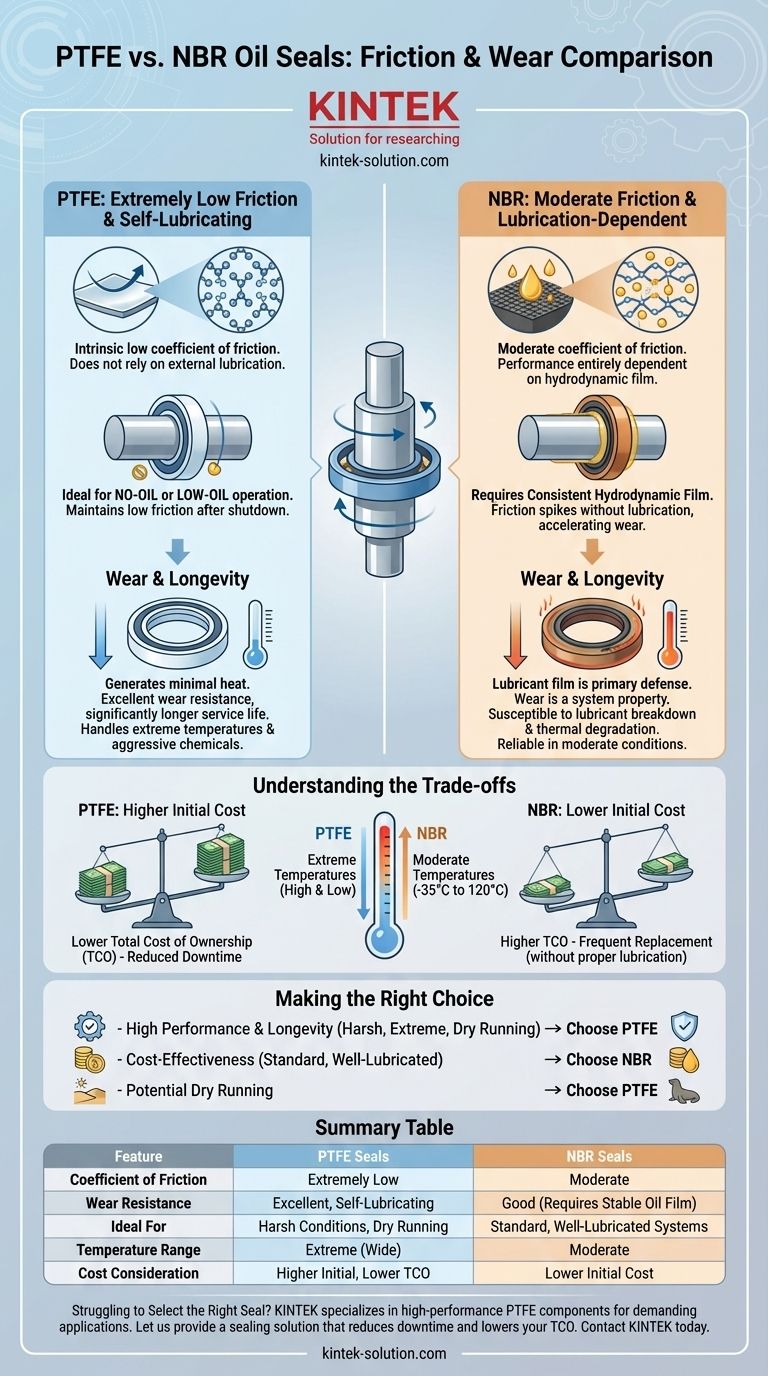

The Fundamental Difference in Friction

The distinct molecular structures of PTFE and NBR create fundamentally different behaviors at the sealing surface. This difference dictates their suitability for various applications.

PTFE's Self-Lubricating Nature

PTFE possesses an extremely low coefficient of friction, one of the lowest of any solid material. This property is intrinsic, meaning it does not rely on external lubrication to function effectively.

This makes PTFE seals ideal for applications with no-oil or low-oil operation. They maintain their low-friction characteristics even after a prolonged shutdown and immediate restart, preventing high initial breakaway torque.

NBR's Reliance on Lubrication

NBR is a versatile elastomer, but it has a moderate coefficient of friction. Its performance is entirely dependent on maintaining a hydrodynamic film—a thin layer of lubricant—between the seal lip and the shaft.

If this lubricant film breaks down due to heat, lack of oil, or contamination, friction increases rapidly. This spike in friction generates excessive heat, which accelerates material degradation and leads to seal failure.

How Friction Impacts Wear and Seal Longevity

Friction is the direct precursor to heat and wear. How each material manages friction is the key to its service life.

Low Friction, Low Wear (PTFE)

Because PTFE generates very little friction, it also produces minimal heat at the contact point. This prevents thermal degradation of the seal material, even at high surface speeds.

The result is excellent wear resistance and a significantly longer service life, particularly in applications that push the boundaries of temperature, speed, or lubrication.

The Role of the Lubricant Film (NBR)

For an NBR seal, the lubricant is the primary defense against wear. As long as the oil film is stable and clean, the seal can provide a long and reliable service life in moderate conditions.

However, the wear characteristics of NBR are not a property of the material alone; they are a property of the entire system. Any interruption to the lubricant supply will cause accelerated wear and a rapid decline in sealing performance.

Understanding the Trade-offs

Choosing a seal material is never just about one performance metric. The correct decision requires evaluating the complete operational context.

Cost vs. Total Cost of Ownership

NBR is a widely available and highly affordable material, making it the default choice for countless standard applications. Its low upfront cost is a major advantage.

PTFE seals are more expensive due to the cost of the raw material and manufacturing processes. However, their longevity in harsh conditions can lead to a lower total cost of ownership by reducing downtime and replacement frequency.

Operating Environment and Media

Your choice is heavily influenced by temperature and chemical exposure. PTFE excels in extreme temperatures (both high and low) and is resistant to a wide range of aggressive chemicals.

NBR performs reliably within a moderate temperature range (typically -35°C to 120°C) and is best suited for standard mineral oils and fuels. It can degrade when exposed to aggressive solvents or synthetic lubricants for which it is not formulated.

Making the Right Choice for Your Application

An effective decision aligns the material's strengths with your application's specific demands.

- If your primary focus is high performance and longevity in harsh conditions: Choose PTFE for its low friction, superior wear resistance, and tolerance for extreme temperatures or aggressive chemicals.

- If your primary focus is cost-effectiveness in standard, well-lubricated systems: NBR offers predictable and reliable performance at a significantly lower cost, making it the ideal choice for general-purpose applications.

- If your application involves potential dry running or intermittent lubrication: PTFE is the only viable option, as its self-lubricating properties prevent the immediate wear and failure that NBR would experience.

Ultimately, selecting the right seal material is about matching its inherent properties to the specific operational and economic demands of your system.

Summary Table:

| Feature | PTFE Seals | NBR Seals |

|---|---|---|

| Coefficient of Friction | Extremely Low | Moderate |

| Wear Resistance | Excellent, Self-Lubricating | Good (Requires Stable Oil Film) |

| Ideal For | Harsh Conditions, Dry Running | Standard, Well-Lubricated Systems |

| Temperature Range | Extreme (Wide) | Moderate |

| Cost Consideration | Higher Initial, Lower TCO | Lower Initial Cost |

Struggling to Select the Right Seal for Your Demanding Application?

Choosing between PTFE and NBR is critical for performance, longevity, and cost-efficiency. The experts at KINTEK can help you navigate these trade-offs.

We specialize in manufacturing high-performance PTFE components (including seals, liners, and labware) for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume production run, our focus on precision ensures a perfect fit and superior performance.

Let us provide a sealing solution that reduces downtime and lowers your total cost of ownership.

Contact KINTEK today for a consultation and let our expertise seal your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry