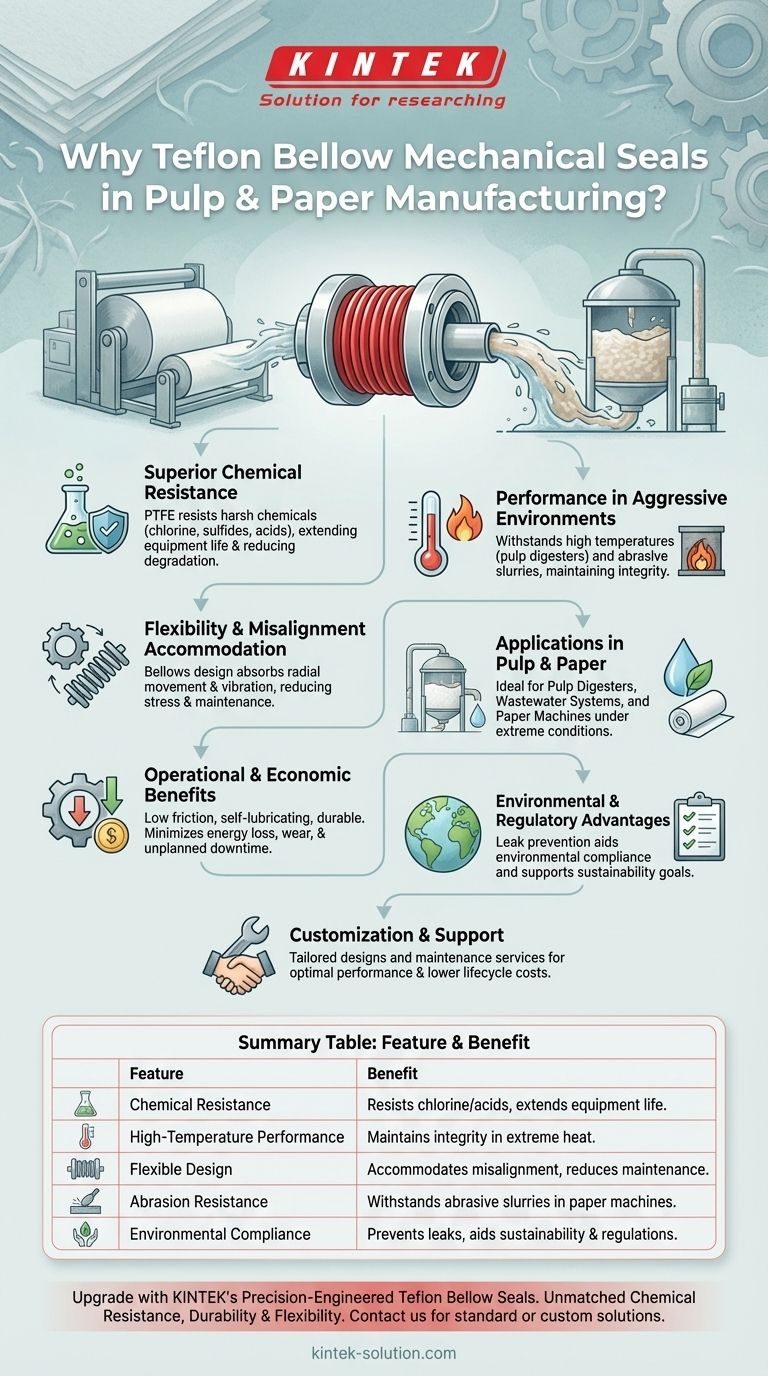

Teflon bellow mechanical seals are highly suitable for pulp and paper manufacturing due to their unique combination of chemical resistance, durability, and adaptability to harsh industrial conditions. These seals excel in environments with aggressive chemicals, high temperatures, and abrasive materials, ensuring reliable performance while minimizing maintenance and downtime. Their design accommodates shaft misalignment and movement, making them ideal for dynamic applications like pulp digesters, paper machine rollers, and wastewater systems. Additionally, their environmental benefits and compliance with regulatory standards further enhance their value in this industry.

Key Points Explained:

-

Superior Chemical Resistance

- Teflon bellow seal materials, particularly PTFE, resist corrosion from harsh chemicals used in pulp and paper processes (e.g., chlorine, sulfides, and acids).

- This prevents seal degradation and extends equipment lifespan, reducing replacement frequency.

-

Performance in Aggressive Environments

- They withstand high temperatures (e.g., in pulp digesters) and abrasive slurries without losing sealing integrity.

- Example: Reliable sealing in paper machine rollers exposed to steam and caustic cleaning agents.

-

Flexibility and Misalignment Accommodation

- The bellows design absorbs radial shaft movement and vibration, common in rotating equipment like pumps.

- Reduces stress on seals and adjacent components, lowering maintenance costs.

-

Applications in Pulp and Paper Manufacturing

- Pulp digesters/washers: Seals endure extreme heat and chemical exposure.

- Wastewater systems: Prevent leaks of contaminated fluids, aiding environmental compliance.

- Paper machines: Maintain seal integrity despite temperature fluctuations and abrasive coatings.

-

Operational and Economic Benefits

- Low friction & self-lubricating properties: Minimize energy loss and wear.

- Durability: Reduces unplanned downtime and associated production losses.

-

Environmental and Regulatory Advantages

- Leak prevention aligns with environmental regulations by containing hazardous substances.

- Supports sustainability goals through long service life and reduced waste.

-

Customization and Support

- Manufacturers offer tailored designs for specific equipment (e.g., oversized bellows for high-misalignment pumps).

- Maintenance services ensure optimal performance, further lowering lifecycle costs.

By addressing these critical needs, Teflon bellow seals provide a robust, cost-effective solution for the demanding conditions of pulp and paper manufacturing.

Summary Table:

| Feature | Benefit |

|---|---|

| Chemical Resistance | Resists harsh chemicals like chlorine and acids, extending equipment life. |

| High-Temperature Performance | Maintains integrity in extreme heat (e.g., pulp digesters). |

| Flexible Design | Accommodates shaft misalignment, reducing wear and maintenance costs. |

| Abrasion Resistance | Withstands abrasive slurries in paper machines and wastewater systems. |

| Environmental Compliance | Prevents leaks, aiding in regulatory adherence and sustainability goals. |

Upgrade your pulp and paper manufacturing with KINTEK's precision-engineered Teflon bellow seals. Our PTFE components are designed for harsh industrial environments, offering unmatched chemical resistance, durability, and flexibility. Whether you need standard or custom solutions, we provide end-to-end support—from prototyping to high-volume production. Contact us today to discuss how our seals can optimize your operations and reduce downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do PTFE seals contribute to reducing maintenance costs? Slash Costs with Superior Durability

- How does PTFE contribute to pharmaceutical manufacturing? Ensure Product Purity and Compliance

- What are the primary functions of washers in mechanical assemblies? Ensure Joint Reliability & Prevent Damage

- How does the PTFE lining in butterfly valves protect against harsh conditions? Ensure Long-Term Reliability

- What are the key features of PTFE lined valves? Maximize Safety and Cut Costs with Corrosion-Resistant Valves

- Are Teflon parts capable of withstanding high temperatures? Understanding the 260°C Limit for Performance

- What are the advantages of using PTFE in electric actuated butterfly valves? Boost Actuator Life & Chemical Resistance

- What are the practical benefits of using PTFE components? Boost Reliability & Cut Costs in Harsh Environments