In short, PTFE seals reduce maintenance costs by lasting significantly longer and protecting the equipment they are a part of. Their unique combination of extreme durability, low-friction properties, and chemical inertness means they fail less often, require fewer replacements, and minimize wear and tear on expensive machinery, directly cutting down on labor, parts, and costly operational downtime.

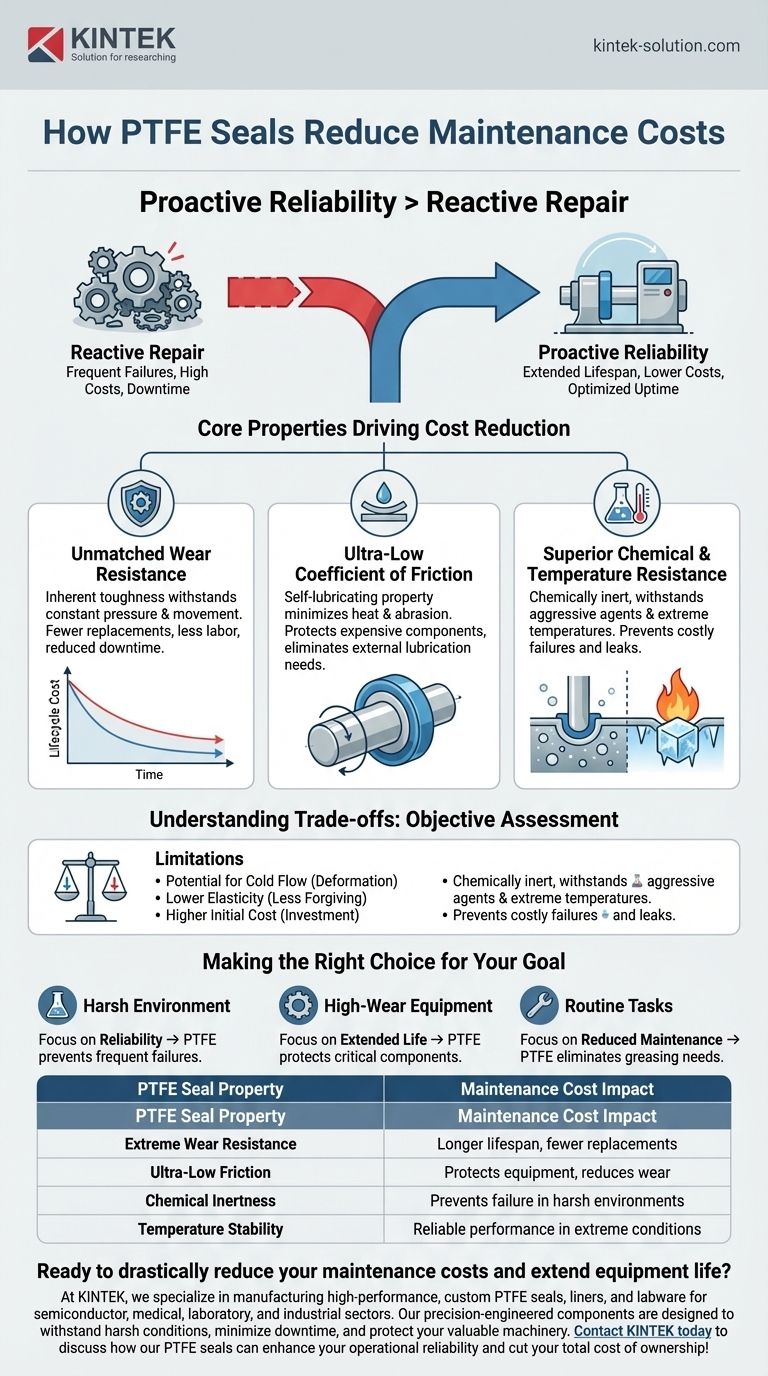

The core reason PTFE seals lower long-term costs is that they shift the focus from reactive repair to proactive reliability. By resisting the primary causes of seal failure—friction, heat, chemical attack, and wear—they drastically reduce the frequency and cost of maintenance interventions over the equipment's entire lifecycle.

The Core Properties of PTFE Driving Cost Reduction

To understand how PTFE (Polytetrafluoroethylene) delivers these savings, we need to look at its fundamental material properties. Each characteristic directly counteracts a common cause of maintenance expenditure.

Unmatched Wear Resistance and Durability

The inherent toughness of PTFE makes it highly resistant to physical degradation. This is especially critical in dynamic applications like reciprocating pistons or rotating shafts.

Because the material withstands constant movement and pressure, the seals do not wear out quickly. This directly extends their operational lifespan, meaning fewer replacement cycles are needed.

Fewer replacements translate immediately to lower costs for parts, labor, and the associated downtime required to perform the maintenance.

Ultra-Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is a primary driver of cost savings.

This low friction minimizes heat generation and abrasive wear on both the seal and the component it is sealing against, such as a valve stem or rotary shaft. This protects expensive equipment parts from damage, avoiding costly repairs or replacements.

Furthermore, it eliminates the need for external lubrication in many systems, saving on the cost of lubricants and the labor required to apply them.

Superior Chemical and Temperature Resistance

PTFE is nearly chemically inert, meaning it can withstand a vast range of aggressive chemicals, solvents, and corrosive agents without degrading.

In applications like chemical plants or processing facilities, seals made from other materials would quickly fail, leading to leaks, safety hazards, and emergency shutdowns. PTFE's resilience prevents these costly failures.

This stability also applies across a wide temperature range, ensuring the seal maintains its integrity and performance in both extreme heat and cold.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective assessment requires understanding their limitations.

Potential for Cold Flow

PTFE can be susceptible to "cold flow" or creep, where the material slowly deforms under sustained pressure, especially at elevated temperatures. This can eventually lead to a loss of sealing force.

Proper seal design, often incorporating fillers like glass, carbon, or bronze, is critical to mitigate this effect and ensure long-term dimensional stability.

Lower Elasticity Compared to Elastomers

Unlike rubber or other elastomers, PTFE has very little "memory" or elasticity. Once deformed, it does not readily return to its original shape.

This means installation requires greater care to avoid damaging the seal. It also means they are less forgiving of imperfections in hardware surfaces compared to more pliable materials.

Higher Initial Cost

The initial procurement cost of a PTFE seal is often higher than that of a standard elastomeric seal.

The decision to use PTFE is therefore an investment. The higher upfront cost is justified by the significant reduction in total cost of ownership through lower maintenance, reduced downtime, and longer equipment life.

Making the Right Choice for Your Goal

Ultimately, the decision to use PTFE seals should be based on your primary operational objective.

- If your primary focus is reliability in harsh chemical environments: PTFE is the definitive choice, as its chemical inertness will prevent frequent failures and costly leaks.

- If your primary focus is extending the life of high-wear equipment: The low-friction and durable nature of PTFE will protect critical components and drastically reduce replacement frequency.

- If your primary focus is reducing routine maintenance tasks: PTFE's self-lubricating properties eliminate the need for regular greasing, freeing up maintenance resources.

Investing in the right material for the application is the most effective maintenance strategy you can deploy.

Summary Table:

| PTFE Seal Property | Maintenance Cost Impact |

|---|---|

| Extreme Wear Resistance | Longer lifespan, fewer replacements |

| Ultra-Low Friction | Protects equipment, reduces wear |

| Chemical Inertness | Prevents failure in harsh environments |

| Temperature Stability | Reliable performance in extreme conditions |

Ready to drastically reduce your maintenance costs and extend equipment life? At KINTEK, we specialize in manufacturing high-performance, custom PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE components are designed to withstand harsh conditions, minimize downtime, and protect your valuable machinery. Whether you need a prototype or a high-volume order, our team is here to provide a solution tailored to your specific application. Contact KINTEK today to discuss how our PTFE seals can enhance your operational reliability and cut your total cost of ownership!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Which industries commonly use PTFE seals and why? Unlock Unmatched Performance in Harsh Environments

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability

- What role does proactive maintenance play in the lifespan of PTFE Expansion Bellows? Maximize Reliability and Uptime

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal

- What are the advantages of Teflon square bars? Solve Extreme Engineering Challenges

- What are the limitations of PTFE impellers in terms of durability? Balancing Chemical Resistance and Mechanical Wear

- What is a PTFE rotary seal and how is it designed? A Guide to High-Performance Sealing

- What are the key properties of virgin Teflon balls? Leverage Superior Chemical & Thermal Resistance