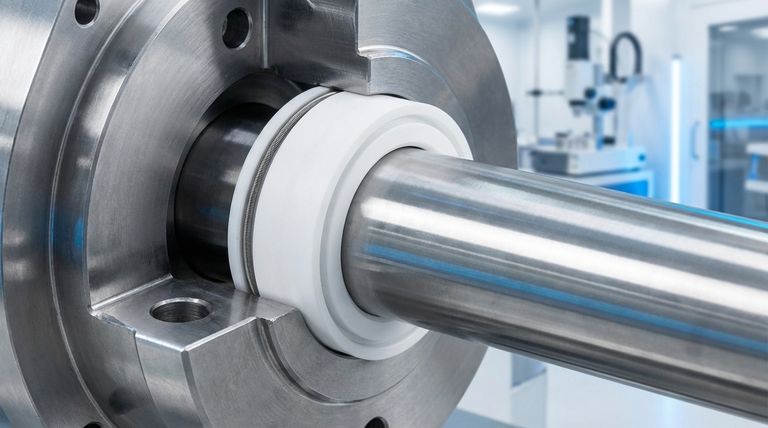

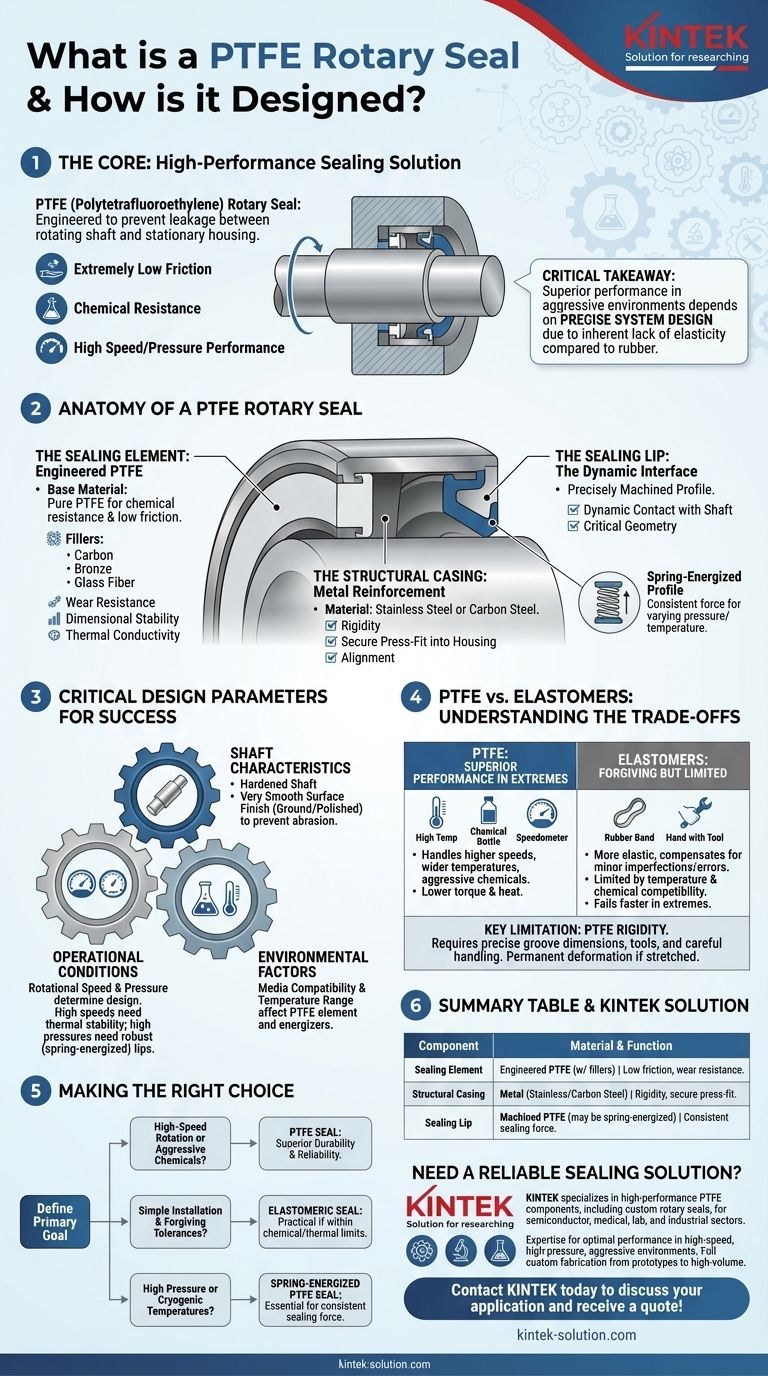

At its core, a Polytetrafluoroethylene (PTFE) rotary seal is a high-performance component designed to prevent leakage between a rotating shaft and a stationary housing. It is engineered from a specialized fluoropolymer known for its extremely low friction and chemical resistance, often housed in a metal case and reinforced with fillers like carbon or bronze to enhance its mechanical properties for demanding conditions.

The critical takeaway is that while PTFE offers superior performance in high-speed, high-pressure, and chemically aggressive environments, its successful implementation depends entirely on a precise system design that accommodates its inherent lack of elasticity compared to traditional rubber seals.

The Anatomy of a PTFE Rotary Seal

Understanding a PTFE seal requires looking at its primary components, each serving a distinct function in the sealing system.

The Sealing Element: Engineered PTFE

The heart of the seal is the PTFE element itself. Pure PTFE provides excellent chemical resistance and a low coefficient of friction, minimizing heat generation and wear on the shaft.

To handle higher pressures or abrasive media, this base material is often blended with fillers like carbon, glass fiber, or bronze. These additives significantly improve wear resistance, dimensional stability, and thermal conductivity.

The Structural Casing: Metal Reinforcement

Most PTFE rotary seals include an outer metal casing, typically made of stainless steel or carbon steel.

This casing provides structural rigidity and allows for a secure press-fit into the housing bore. It ensures the seal remains stationary and properly aligned while the shaft rotates.

The Sealing Lip: The Dynamic Interface

The sealing lip is the precisely machined feature on the inner diameter of the PTFE element that makes dynamic contact with the rotating shaft.

Its geometry is critical for performance. Designs can range from a simple, flexible lip to more complex spring-energized profiles, where a metal spring provides consistent force on the shaft to maintain a seal under varying pressures and temperatures.

Critical Design Parameters for Success

Unlike a forgiving rubber seal, a PTFE seal's performance is inextricably linked to the design of the entire rotary system.

Shaft Characteristics: The Mating Surface

The condition of the shaft is paramount. A hardened shaft with a very smooth surface finish (typically ground and polished) is required to prevent abrasion of the PTFE lip and ensure a reliable seal.

Operational Conditions: Speed and Pressure

The combination of rotational speed and system pressure dictates the appropriate seal design and material. High speeds generate significant frictional heat, requiring materials with good thermal stability, while high pressures demand a more robust lip design, often spring-energized.

Environmental Factors: Media and Temperature

While PTFE is resistant to most chemicals, engineers must confirm compatibility with the specific media being sealed. The operating temperature range is also crucial, as it affects both the PTFE element and any energizing springs.

Understanding the Trade-offs: PTFE vs. Elastomers

Choosing PTFE over a conventional elastomeric (rubber) seal involves a clear set of trade-offs that must be carefully considered.

Advantage: Superior Performance in Extremes

PTFE seals excel where rubber fails. They can handle significantly higher surface speeds, wider temperature ranges, and more aggressive chemicals without degrading. Their low-friction nature also means lower torque requirements and less heat generation.

The Key Limitation: Lack of Elasticity

The most significant difference is PTFE's rigidity. It does not have the "memory" or elasticity of rubber. This means it cannot compensate for significant hardware imperfections or installation errors.

Stretching or mishandling a PTFE seal during installation can permanently deform it, leading to immediate failure. This demands precise groove dimensions, proper installation tools, and careful handling.

Making the Right Choice for Your Application

Selecting the correct seal technology requires aligning the component's capabilities with your primary engineering goal.

- If your primary focus is high-speed rotation or aggressive chemicals: A PTFE seal is the superior technical solution, offering durability and reliability where elastomers would quickly fail.

- If your primary focus is simple installation and forgiving tolerances: A traditional elastomeric seal is often more practical, provided it meets the application's chemical and thermal limits.

- If you are dealing with high pressure or cryogenic temperatures: A spring-energized PTFE seal is likely the only viable option to maintain a consistent and reliable sealing force.

Ultimately, successful sealing is not about a single component but about designing a complete system where the seal, shaft, and housing work in concert.

Summary Table:

| Component | Material & Function |

|---|---|

| Sealing Element | Engineered PTFE with fillers (carbon, bronze) for low friction and wear resistance. |

| Structural Casing | Metal (stainless/carbon steel) for rigidity and secure press-fit into housing. |

| Sealing Lip | Machined PTFE interface; may be spring-energized for consistent sealing force. |

Need a reliable sealing solution for demanding conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom rotary seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are designed for optimal performance in high-speed, high-pressure, and chemically aggressive environments.

We offer full custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit and superior durability.

Contact KINTEK today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability