The fundamental challenge in cleaning Teflon residue from a screw and barrel is that the very properties that make Teflon an excellent non-stick surface—its strong chemical bond to metal and high thermal stability—also make it incredibly difficult to remove once it has adhered under processing conditions.

The core issue is not simply about scrubbing harder; it's a materials science problem. Effective cleaning requires a strategy that can safely break the powerful bond Teflon forms with metal surfaces without damaging the precision-engineered equipment.

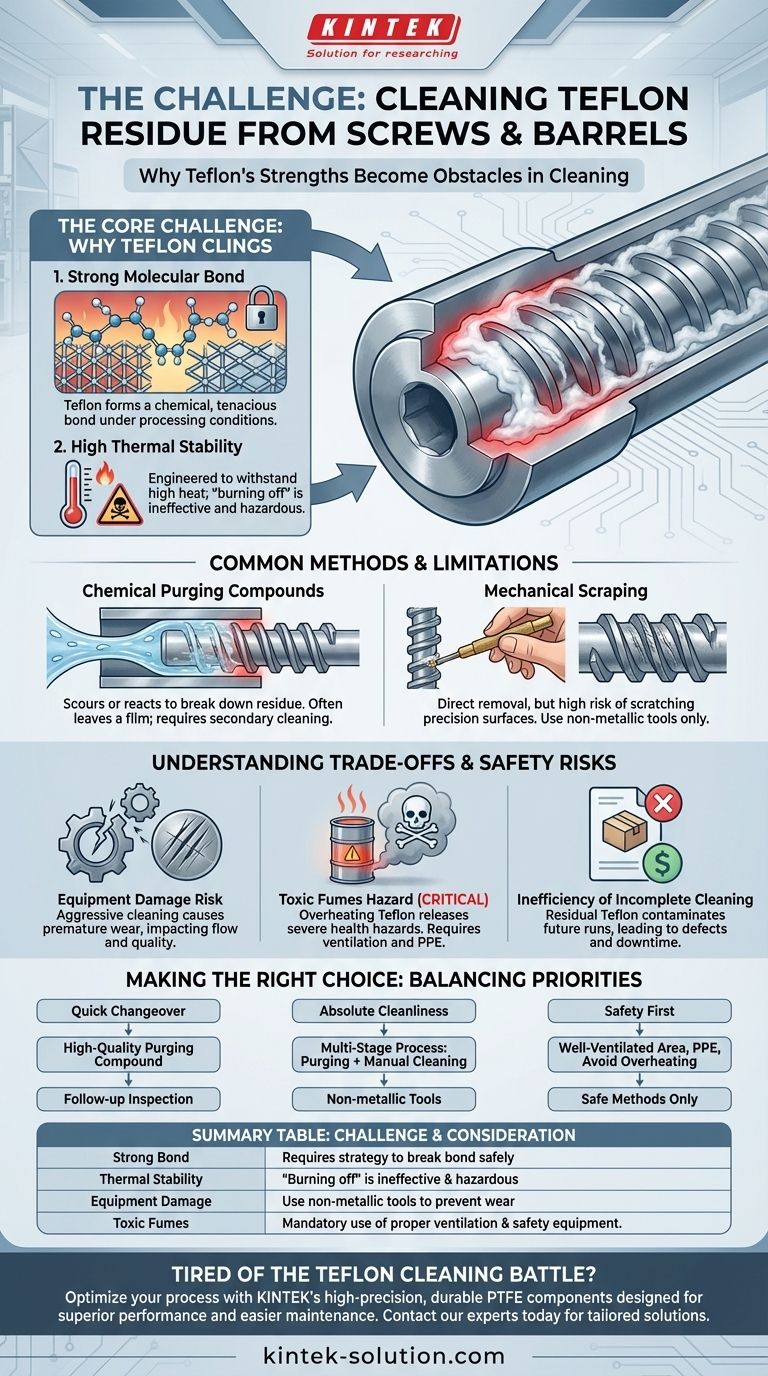

The Core Challenge: Why Teflon Clings to Metal

The difficulty in removing Teflon, or Polytetrafluoroethylene (PTFE), stems from its inherent chemical and physical properties. It is designed to be resilient, which becomes a liability during cleaning.

The Strong Molecular Bond

Under the heat and pressure of an extruder, Teflon forms a tenacious bond with the metal surfaces of the screw and barrel. This isn't just a physical adhesion; it's a chemical interaction that makes the residue an integrated layer on the steel.

High Thermal Stability

Teflon is engineered to withstand high temperatures without degrading. This means that simply increasing the heat to "burn it off" is often ineffective at normal processing temperatures and can be extremely hazardous if done improperly.

Common Cleaning Methods and Their Limitations

Because no single method is perfect, operators often combine approaches. Understanding the limitations of each is key to developing an effective process.

Chemical Purging Compounds

Purging compounds are specialized materials run through the machine to push out old residue. While effective for many polymers, they often struggle to completely dissolve Teflon.

These compounds typically work by mechanically scouring the screw and barrel or by creating a chemical reaction that helps break down the residue. However, they often leave a thin film of Teflon behind, requiring a secondary cleaning step.

Mechanical Scraping

Manual cleaning with tools is a direct approach to removing stubborn deposits. The primary challenge here is the significant risk of damaging the equipment.

Using hard, metallic tools can easily scratch, gouge, or otherwise compromise the finely machined surfaces of the screw and barrel. This damage can create new areas for material to hang up, worsening the problem over time.

Understanding the Trade-offs and Safety Risks

Choosing a cleaning method involves balancing effectiveness with the critical need to protect both your equipment and your personnel.

Risk of Equipment Damage

Aggressive mechanical cleaning is a common cause of premature wear on screws and barrels. Even small scratches can disrupt the flow of material, impact product quality, and reduce the lifespan of expensive components. Always use non-metallic tools made from materials like brass or bronze.

The Hazard of Toxic Fumes

This is the most critical safety consideration. When Teflon is heated to its decomposition temperature (well above normal processing heat), it can release toxic fumes that are a severe health hazard. Any "burn-out" method must be performed in a well-ventilated area with proper safety equipment.

The Inefficiency of Incomplete Cleaning

Leaving even a small amount of Teflon residue can contaminate subsequent production runs, leading to product defects and wasted material. The difficulty of removal often leads to a compromise between downtime and cleanliness, which can have downstream financial consequences.

Making the Right Choice for Your Goal

Your cleaning strategy should be dictated by your specific operational needs, balancing cleanliness, time, and safety.

- If your primary focus is a quick changeover: A high-quality purging compound designed for high-temperature resins is your best first step, but be prepared for a follow-up inspection.

- If your primary focus is absolute cleanliness for a sensitive material: You will likely need a multi-stage process combining a purging compound with a full screw pull for careful, manual cleaning with non-metallic tools.

- If your primary focus is safety above all else: Prioritize working in a well-ventilated area, wearing all necessary protective gear, and strictly avoiding any method that could overheat the Teflon residue.

Ultimately, mastering Teflon cleaning comes from understanding that you are battling the material's core properties, which requires a deliberate and safety-conscious approach.

Summary Table:

| Challenge | Core Issue | Key Consideration |

|---|---|---|

| Strong Bond | Teflon chemically bonds to metal under heat/pressure. | Requires a strategy to break the bond without damage. |

| Thermal Stability | Teflon doesn't degrade at normal processing temperatures. | 'Burning off' is often ineffective and highly hazardous. |

| Equipment Damage | Mechanical scraping can scratch and gouge precision surfaces. | Use non-metallic tools (e.g., brass) to prevent wear. |

| Toxic Fumes | Overheating Teflon releases hazardous decomposition products. | Mandatory use of proper ventilation and safety equipment. |

Tired of the Teflon cleaning battle?

Cleaning PTFE (Teflon) residue doesn't have to mean compromising between equipment safety, operator health, and production downtime. At KINTEK, we understand the precise challenges faced by the semiconductor, medical, laboratory, and industrial sectors.

We manufacture high-precision, durable PTFE components—including seals, liners, and labware—designed for superior performance and easier maintenance. Whether you need a custom-fabricated solution from prototype to high-volume orders, our expertise ensures your components meet the highest standards, reducing cleaning challenges from the start.

Let us help you optimize your process. Contact our experts today for a consultation on high-performance PTFE solutions tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments