At their core, the advantages of Teflon square bars stem from a unique combination of chemical inertness, thermal stability, and an extremely low coefficient of friction. This makes them a high-performance material for creating custom parts that must function reliably in harsh chemical, thermal, or electrical environments where conventional materials would quickly fail.

The true value of Teflon (PTFE) is not found in a single property, but in its ability to solve engineering problems in extreme conditions. It is the go-to material when you need components to resist aggressive chemicals, withstand wide temperature ranges, and provide a self-lubricating, non-stick surface.

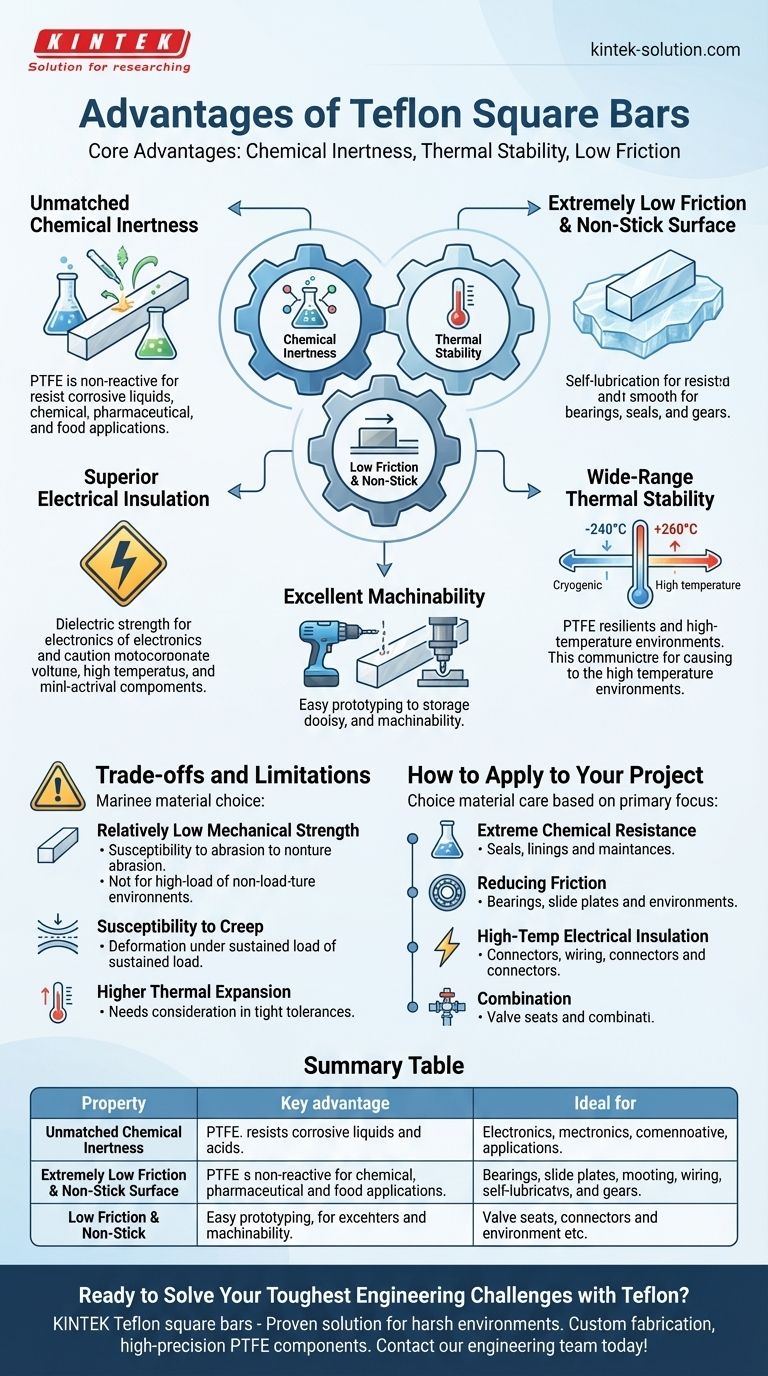

The Core Properties That Define Teflon's Performance

To understand why Teflon square bars are so widely used, we need to look beyond a simple list of features. Each core property addresses a specific set of engineering challenges.

Unmatched Chemical Inertness

Teflon, technically Polytetrafluoroethylene (PTFE), is one of the most non-reactive substances known. It is virtually inert to almost all industrial chemicals, acids, and bases.

This property makes it indispensable for components used in chemical processing, pharmaceuticals, and food handling where corrosion or contamination is a primary concern.

Extremely Low Friction and Non-Stick Surface

Teflon has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This means objects slide against it with very little resistance.

This "self-lubricating" characteristic is ideal for creating bearings, seals, slide plates, and gears that operate smoothly without external lubricants. Its non-stick nature also ensures easy cleaning and prevents material buildup.

Wide-Range Thermal Stability

Teflon performs consistently across an exceptionally broad temperature spectrum, handling continuous service temperatures up to approximately 260°C (500°F) and remaining durable at cryogenic temperatures as low as -240°C (-400°F).

This resilience makes it suitable for components in high-temperature industrial processes as well as applications in extreme cold, where other plastics would become brittle and fail.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with high dielectric strength and low a dissipation factor. It does not conduct electricity and resists high voltages.

These properties are critical for manufacturing insulators, connectors, and components for high-frequency electronics where signal integrity and safety are paramount.

Excellent Machinability

Despite its high-performance characteristics, Teflon is a relatively soft material that is easy to machine. Square bars can be readily cut, drilled, and milled into precise, custom components.

This allows for the rapid prototyping and production of complex parts tailored to specific application needs, a significant advantage over harder-to-work materials.

Understanding the Trade-offs and Limitations

No material is perfect. While Teflon's properties are exceptional, understanding its limitations is critical for proper application.

Relatively Low Mechanical Strength

Compared to engineering metals or even other high-performance plastics like PEEK, Teflon has lower tensile strength and is more susceptible to abrasion. It is not intended for high-load structural applications.

Its strength lies in its unique surface and resistance properties, not its ability to bear heavy mechanical stress.

Susceptibility to Creep

Under a continuous, sustained load, Teflon can slowly deform over time—a phenomenon known as "creep." This must be accounted for in the design of parts like seals and gaskets that are under constant pressure.

Higher Thermal Expansion

Teflon expands and contracts with temperature changes more significantly than metals. In designs with very tight tolerances where components are mated with metal parts, this difference in thermal expansion must be considered to avoid binding or failure.

How to Apply This to Your Project

Your choice of material should always be driven by the primary challenge you need to solve. Teflon square bars offer a specialized solution set for demanding environments.

- If your primary focus is extreme chemical resistance: Teflon is an unparalleled choice for seals, linings, and components in corrosive chemical environments.

- If your primary focus is reducing friction: Its self-lubricating, non-stick properties make it ideal for low-wear bearings, slide plates, and easy-to-clean surfaces.

- If your primary focus is high-temperature electrical insulation: Its dielectric strength and thermal stability are critical for connectors and wiring in demanding electronics and aerospace applications.

- If your primary focus is a combination of these: Teflon provides a unique synergy of properties for complex parts like valve seats, which must seal tightly (resilience), resist chemicals (inertness), and operate smoothly (low friction).

Ultimately, Teflon square bars provide a reliable and machinable solution for engineering challenges that demand high performance where other materials cannot survive.

Summary Table:

| Property | Key Advantage | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases. | Chemical processing, pharmaceutical, and food handling components. |

| Low Friction | Self-lubricating, non-stick surface with an extremely low coefficient of friction. | Bearings, seals, slide plates, and gears requiring smooth operation. |

| Thermal Stability | Performs consistently from -240°C to +260°C (-400°F to +500°F). | High-temperature processes and cryogenic applications. |

| Electrical Insulation | Excellent dielectric strength and insulation properties. | Connectors, insulators, and high-frequency electronics. |

| Machinability | Easy to cut, drill, and mill into precise custom parts. | Rapid prototyping and production of complex components. |

Ready to Solve Your Toughest Engineering Challenges with Teflon?

Teflon square bars from KINTEK are the proven solution for components that must survive in harsh chemical, thermal, and electrical environments. Our expertise in manufacturing high-precision PTFE components—including seals, liners, and custom labware—ensures your parts perform reliably where others fail.

We specialize in custom fabrication, from initial prototypes to high-volume production runs, for the semiconductor, medical, laboratory, and industrial sectors.

Let's discuss how our precision Teflon components can enhance your project's performance and reliability. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What factors should be considered when choosing PTFE bars for chemical applications? Select the Right Grade for Your Process

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- What are the key properties of PTFE that make it suitable for high-performance applications? Unlock Extreme Performance

- What are the advantages of PTFE rod over other materials? Superior Chemical & Thermal Performance

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems