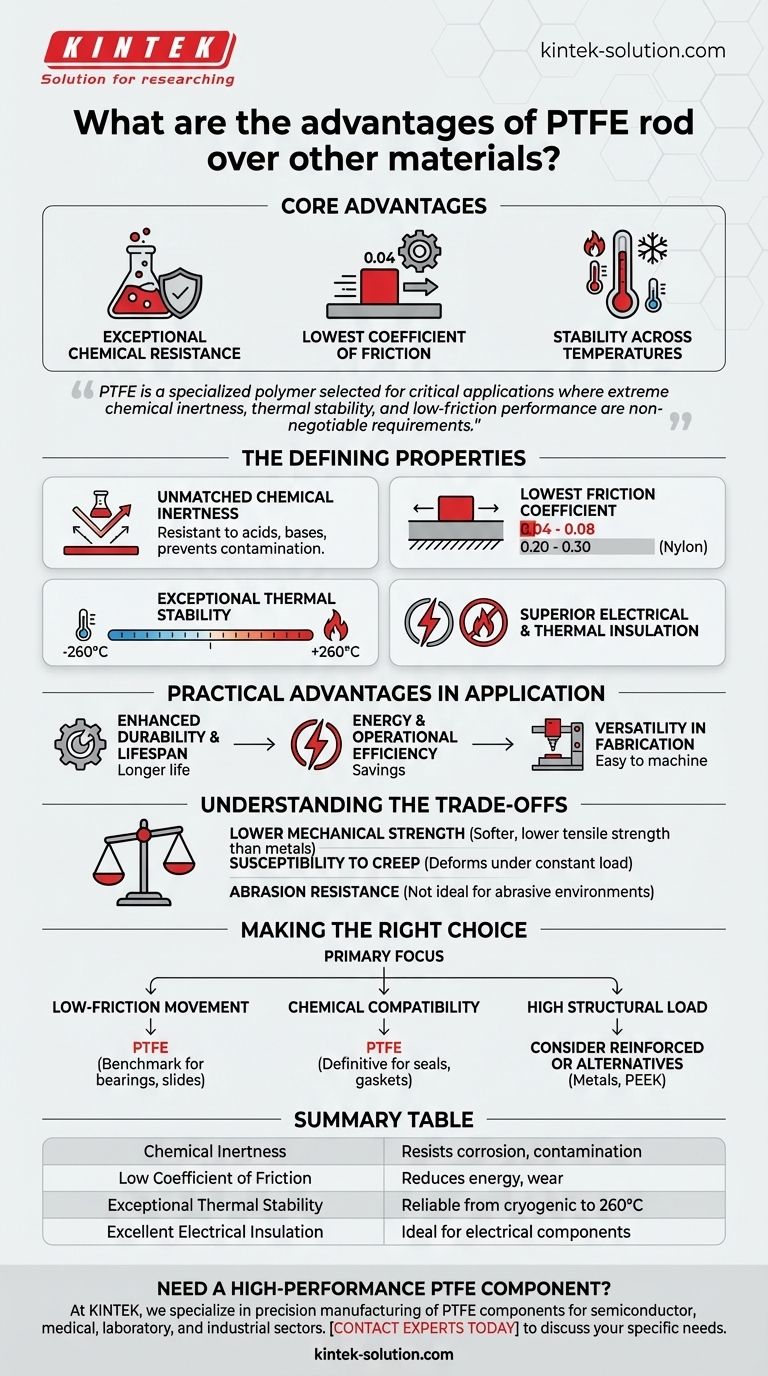

The primary advantages of PTFE rod are its exceptional chemical resistance, its stability across a wide range of temperatures, and its uniquely low coefficient of friction—the lowest of any solid engineering material. This combination of properties makes it a high-performance solution for demanding industrial environments where other materials would quickly fail.

PTFE is not simply another plastic; it is a specialized polymer selected for critical applications where extreme chemical inertness, thermal stability, and low-friction performance are non-negotiable requirements.

The Defining Properties of PTFE

The advantages of PTFE stem from a few core characteristics that set it apart from metals, ceramics, and other polymers. Understanding these properties is key to knowing when to specify it for a project.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and bases. This makes it an ideal material for components used in corrosive environments, as it will not corrode or degrade.

This inertness ensures a long service life and prevents contamination of the substances it comes into contact with, which is critical in chemical processing and food-grade applications.

The Lowest Coefficient of Friction

PTFE has an exceptionally low coefficient of friction, with values typically cited between 0.04 and 0.08. This is significantly lower than other common materials like Nylon (0.20-0.30) or even lubricated steel.

Practically, this means parts made from PTFE slide or rotate with minimal resistance. This property is the reason PTFE is the benchmark material for high-performance bearings, bushings, and low-friction sliding surfaces.

Exceptional Thermal Stability

PTFE maintains its properties across a very broad temperature range. It can operate continuously in extreme environments, from cryogenic temperatures up to approximately 260°C (500°F).

This thermal stability ensures reliability and dimensional consistency where other plastics would become brittle or melt.

Superior Electrical and Thermal Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It is also a good thermal insulator, preventing the transfer of heat.

These properties make it a valuable material for electrical components, connectors, and as a thermal break in assemblies.

Practical Advantages in Application

These fundamental properties translate directly into tangible benefits for performance, reliability, and operational efficiency.

Enhanced Durability and Lifespan

Because PTFE resists chemical attack and wear from friction, components made from it have a significantly longer lifespan. They require less frequent maintenance and replacement compared to parts made from traditional metals or other plastics.

Energy and Operational Efficiency

The extremely low friction of PTFE surfaces reduces the energy required to move sliding or rotating parts. This translates directly into energy savings and improved operational efficiency over the life of the equipment.

Versatility in Fabrication

Despite its high performance, PTFE rod is relatively easy to machine. It can be fabricated into complex shapes and held to tight tolerances, allowing for the creation of precise and custom components for a wide variety of industrial uses.

Understanding the Trade-offs

While PTFE offers unique advantages, it is not the ideal choice for every situation. Being aware of its limitations is crucial for proper material selection.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or metals like steel, PTFE is a relatively soft material. It has lower tensile strength and is not suitable for high-load structural applications without reinforcement (e.g., glass or carbon fiber fill).

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of components that will be under sustained compression, like seals and gaskets.

Abrasion Resistance

While PTFE has an incredibly low-friction surface, it is not highly resistant to abrasion from hard, sharp particles. In environments with abrasive media, a harder material may be a better choice to prevent premature wear.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on whether its unique strengths align with the primary demands of your project.

- If your primary focus is low-friction movement: PTFE is the industry benchmark for bearings, slide plates, and non-stick surfaces, outperforming virtually all other solid materials.

- If your primary focus is chemical compatibility: PTFE's inertness makes it the definitive choice for seals, gaskets, and components in corrosive chemical processing.

- If your primary focus is high structural load: You must consider PTFE's lower mechanical strength; reinforced grades or alternative materials like metals may be necessary.

Ultimately, choosing PTFE is a decision to prioritize performance and reliability in chemically or thermally extreme environments.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, preventing corrosion and contamination. |

| Low Coefficient of Friction | Reduces energy consumption and wear in bearings and sliding parts. |

| Exceptional Thermal Stability | Performs reliably from cryogenic temperatures up to 260°C (500°F). |

| Excellent Electrical Insulation | Ideal for high-performance electrical components and connectors. |

Need a high-performance PTFE component for your critical application?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, bushings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that leverages PTFE's full advantages, tailored to your exact specifications from prototype to high-volume production.

Contact our experts today to discuss how our PTFE solutions can enhance your product's durability, efficiency, and reliability.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- What factors should be considered when choosing PTFE bars for chemical applications? Select the Right Grade for Your Process

- What are PTFE rods and how are they manufactured? A Guide to Their Properties and Production

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- In which types of industrial equipment is PTFE rod commonly used? Essential for Seals, Bearings & Valves