In choosing PTFE bars for chemical applications, your primary considerations must be the specific grade and purity of the material, its mechanical properties under chemical stress, and its verified compatibility with your exact process conditions. While virgin PTFE offers broad chemical resistance, specialized grades are often required for demanding environments involving abrasion or high temperatures, and generic compatibility charts should never be your final point of reference.

The real challenge isn't finding a material that resists chemicals, but ensuring it maintains its structural and chemical integrity under the unique stresses of your specific application. The difference between success and failure often lies in choosing the correct PTFE grade and verifying its performance yourself.

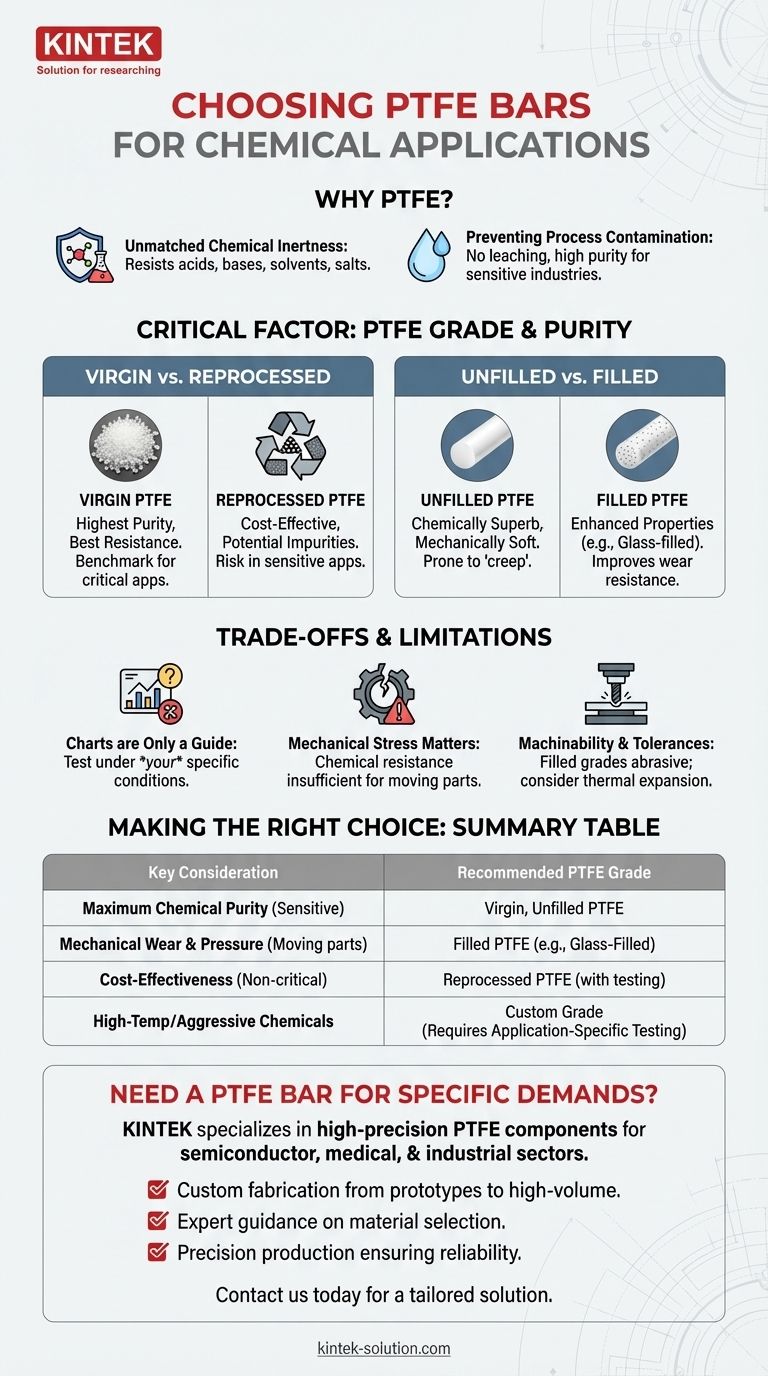

The Foundation: Why PTFE for Chemical Applications?

Polytetrafluoroethylene (PTFE) is a default choice for many chemical-facing components for a clear set of reasons. Understanding these foundational properties helps frame your selection criteria.

Unmatched Chemical Inertness

PTFE is non-reactive and corrosion-resistant against nearly all industrial chemicals, including aggressive acids, bases, solvents, and salts. Its molecular structure, with carbon atoms shielded by fluorine atoms, prevents chemical attack.

Preventing Process Contamination

Because it is so inert, PTFE does not leach substances into the process fluid. This ensures the purity of the end product, which is a non-negotiable requirement in industries like pharmaceuticals, food processing, and semiconductor manufacturing.

Critical Factor #1: PTFE Grade and Purity

Not all PTFE is created equal. The most significant factor in performance is the grade of the polymer, which determines its purity, mechanical properties, and ultimately, its reliability.

Virgin vs. Reprocessed PTFE

Virgin PTFE is made directly from raw resin and offers the highest level of purity and chemical resistance. It is the benchmark for critical applications.

Reprocessed (or mechanical) grade PTFE is made from recycled material. While more cost-effective, it may contain micro-impurities or have an altered chemical structure from the recycling process. This can compromise its chemical resistance and is a significant risk in sensitive applications.

Filled vs. Unfilled PTFE

Unfilled PTFE is the pure polymer. While chemically superb, it is mechanically soft and can be prone to "creep" (deformation under load) and wear.

Filled PTFE incorporates additives to enhance specific properties. These grades are essential when mechanical stress is a factor in addition to chemical exposure. For example, glass-filled PTFE significantly improves wear resistance and reduces creep, making it ideal for seals, gaskets, and bearings in chemical processing equipment. Other fillers like graphite can be used to improve other specific properties.

Understanding the Trade-offs and Limitations

Relying on the general reputation of PTFE without understanding its limitations is a common pitfall. Objectivity requires acknowledging where and how it can fail.

Chemical Compatibility Charts Are Only a Guide

Published chemical resistance charts are a useful starting point, but they are not a guarantee of performance. Many charts are based on limited exposure times (e.g., 48 hours) at room temperature.

You must conduct your own tests under your specific operating conditions—including chemical concentration, temperature, pressure, and exposure duration—to ensure full compatibility.

The Impact of Mechanical Stress

In applications with moving parts, such as valves or pumps, chemical resistance alone is insufficient. The material must also withstand abrasion and maintain its shape under pressure.

An unfilled PTFE bar might be perfectly inert to a chemical but fail rapidly due to wear. This is where a filled grade becomes necessary.

Machinability and Tolerances

While PTFE is generally easy to machine, filled grades can be more abrasive on cutting tools. Furthermore, the material's thermal expansion and softness require specific machining techniques to hold tight tolerances. Factoring in the machinability of your chosen grade is crucial for producing a functional final part.

Making the Right Choice for Your Application

Your selection should be a deliberate decision based on the specific demands of your process. Use these guidelines to steer your choice.

- If your primary focus is maximum chemical purity and resistance in a static role: Choose virgin, unfilled PTFE for its unmatched inertness.

- If your application involves mechanical wear, pressure, or abrasion: Select a filled PTFE, such as glass-filled, to provide the necessary wear resistance and dimensional stability.

- If you are working with a highly aggressive chemical mixture or at elevated temperatures: Do not rely on datasheets alone. Your top priority must be to conduct your own material testing under real-world conditions.

- If you are considering a reprocessed grade for cost savings: Limit its use to non-critical applications and perform rigorous testing to validate its chemical resistance and purity for your specific media.

Ultimately, a successful outcome depends on moving beyond generic specifications and matching the precise material grade to the distinct chemical and mechanical stresses of your environment.

Summary Table:

| Selection Factor | Key Consideration | Recommended PTFE Grade |

|---|---|---|

| Maximum Chemical Purity | Non-reactive, no leaching, critical for sensitive processes | Virgin, Unfilled PTFE |

| Mechanical Wear & Pressure | Applications with abrasion, moving parts, or load | Filled PTFE (e.g., Glass-Filled) |

| Cost-Effectiveness (Non-Critical) | Less aggressive environments, budget constraints | Reprocessed PTFE (with testing) |

| High-Temp/Aggressive Chemicals | Extreme conditions beyond standard charts | Custom Grade (Requires Application-Specific Testing) |

Need a PTFE bar that withstands your specific chemical and mechanical demands?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We provide the right material grade for your application, from virgin PTFE for ultimate purity to filled grades for enhanced durability.

✅ Custom fabrication from prototypes to high-volume orders

✅ Expert guidance on material selection and compatibility

✅ Precision production ensuring part reliability

Contact us today to discuss your requirements and get a solution tailored to your process. Reach out via our contact form for a consultation.

Visual Guide

Related Products

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- How are PTFE extruded rods applied in the food processing industry? Enhancing Hygiene and Efficiency

- What are the advantages of PTFE rod over other materials? Superior Chemical & Thermal Performance

- What are the key properties of PTFE that make it suitable for high-performance applications? Unlock Extreme Performance

- What are the machining advantages of PTFE rod? Achieve Cost-Effective, Complex Parts