In short, proactive maintenance is one of the most critical factors in determining the lifespan and reliability of PTFE expansion bellows. While the PTFE material itself is exceptionally durable, the bellow's operational integrity is directly tied to a consistent maintenance strategy that addresses installation, alignment, and ongoing operational stresses.

The core principle to understand is that most PTFE bellow failures are not due to the material's inherent properties, but rather from mechanical and environmental stresses that a proactive maintenance program is specifically designed to prevent.

The Foundation: Why PTFE Bellows Need Protection

PTFE (Polytetrafluoroethylene) is a remarkable material chosen for its inherent strengths in demanding industrial environments. Understanding these strengths is key to knowing what you need to protect.

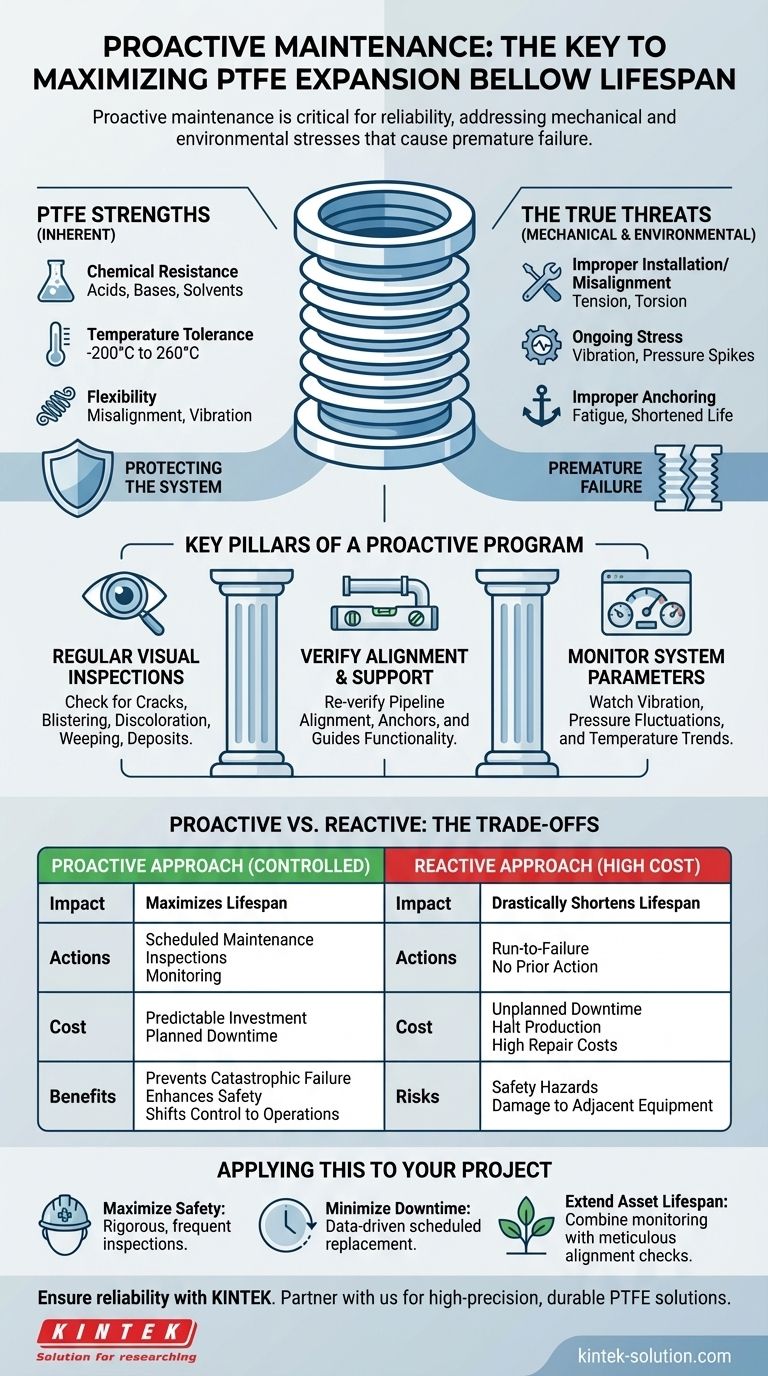

The Inherent Strengths of PTFE

PTFE bellows are prized for their exceptional chemical resistance. They can handle a wide range of aggressive media, including most acids, bases, and solvents, without degradation.

They also offer superior temperature tolerance, operating reliably in extreme conditions from -200 °C to 260 °C.

Finally, their design provides excellent flexibility. This allows them to absorb pipeline misalignment, thermal expansion, and system vibrations, protecting the entire piping system from mechanical stress.

The True Threats: Mechanical and Environmental Stress

While PTFE is chemically inert, the bellow assembly is a mechanical component. Its greatest vulnerabilities are not from the chemicals inside but from the physical forces acting upon it.

The most common causes of premature failure are improper installation and pipeline misalignment. A bellow installed under tension or torsion is already compromised and will fail exponentially faster.

Ongoing vibration, pressure spikes, and improper anchoring of the pipeline add continuous stress cycles that fatigue the bellow's structure, leading directly to a shortened service life.

Key Pillars of a Proactive Maintenance Program

A successful maintenance program moves beyond a "run-to-failure" approach. It focuses on regular, scheduled actions designed to identify and mitigate stress before it leads to a costly failure.

Regular Visual Inspections

This is the simplest and most effective maintenance task. Technicians should look for any signs of cracking, blistering, discoloration, or physical damage on the bellow's surface.

Evidence of weeping or deposits around the flanges can indicate the very early stages of a sealing issue or material breach.

Verifying Alignment and Support

Pipelines can shift over time due to thermal cycles, ground settling, or changes in adjacent equipment.

A core part of maintenance is to periodically re-verify that the pipeline is properly aligned and that all anchors and guides are functioning correctly, ensuring no unintended stress is being placed on the bellow.

Monitoring System Parameters

Keep a close watch on system operating conditions. A sudden increase in vibration, pressure fluctuations, or temperature can indicate a problem elsewhere in the system that is now putting the expansion bellow at risk.

Monitoring these trends allows you to address the root cause before the bellow becomes the point of failure.

Understanding the Trade-offs: Proactive vs. Reactive

Choosing a maintenance strategy is an economic and operational decision. The contrast between a proactive and reactive approach is stark.

The High Cost of a Reactive Approach

Waiting for a bellow to fail is the most expensive strategy. A failure results in unplanned downtime, which can halt entire production lines.

It also introduces significant safety risks if hazardous materials are released. Furthermore, a catastrophic failure can cause damage to expensive adjacent equipment like pumps and vessels.

The Controlled Investment of a Proactive Strategy

Proactive maintenance requires an investment in labor and scheduled, planned downtime. However, these are controlled and predictable costs.

This investment pays for itself by maximizing the lifespan of every component, preventing catastrophic failures, and ensuring a safer operating environment. It shifts control from the equipment to the operations team.

How to Apply This to Your Project

Your maintenance strategy should align directly with your facility's primary operational goals. A proactive approach allows you to manage risk and protect your assets effectively.

- If your primary focus is maximizing safety and preventing hazardous leaks: Implement a rigorous, frequent visual inspection schedule and empower technicians to act immediately on any sign of degradation.

- If your primary focus is minimizing operational downtime: Use a data-driven approach to establish a scheduled replacement program based on operational hours, system cycles, and manufacturer guidelines.

- If your primary focus is extending asset lifespan to its fullest potential: Combine regular monitoring of system parameters with meticulous, periodic checks on pipeline alignment and support structures to mitigate all forms of mechanical stress.

Ultimately, proactive maintenance transforms your PTFE expansion bellows from a potential liability into a predictable and highly reliable system component.

Summary Table:

| Maintenance Approach | Impact on Lifespan | Key Actions |

|---|---|---|

| Proactive | Maximizes Lifespan | Regular visual inspections, alignment checks, system monitoring. |

| Reactive (Run-to-Failure) | Drastically Shortens Lifespan | No action until failure occurs, leading to unplanned downtime. |

Ensure the reliability of your PTFE expansion bellows with KINTEK.

Your operations in the semiconductor, medical, laboratory, and industrial sectors demand components that perform under pressure. KINTEK specializes in manufacturing high-precision, durable PTFE components—including seals, liners, and custom bellows—designed for the most demanding environments.

We help you move beyond reactive maintenance by providing components built for longevity and supporting your proactive strategies with:

- Custom Fabrication: From prototypes to high-volume orders, we engineer solutions to meet your exact specifications and operational stresses.

- Precision Production: Quality-built components that form the foundation of a reliable, low-maintenance system.

Don't let component failure dictate your schedule. Partner with KINTEK for PTFE solutions that enhance safety, minimize downtime, and extend asset lifespan.

Contact our experts today to discuss your project requirements and how our custom PTFE components can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments