The key properties of virgin Teflon balls are their exceptional chemical inertness, thermal stability, and low-friction, self-lubricating surface. They are highly resistant to nearly all industrial chemicals, corrosion, and weathering, while also serving as excellent electrical insulators. These characteristics make them suitable for a wide range of specialized applications, from pump components to medical devices.

While virgin Teflon (PTFE) offers unmatched resistance to chemicals and extreme temperatures, its primary trade-off is its relatively low mechanical strength. Understanding this balance is critical to selecting it for the right application.

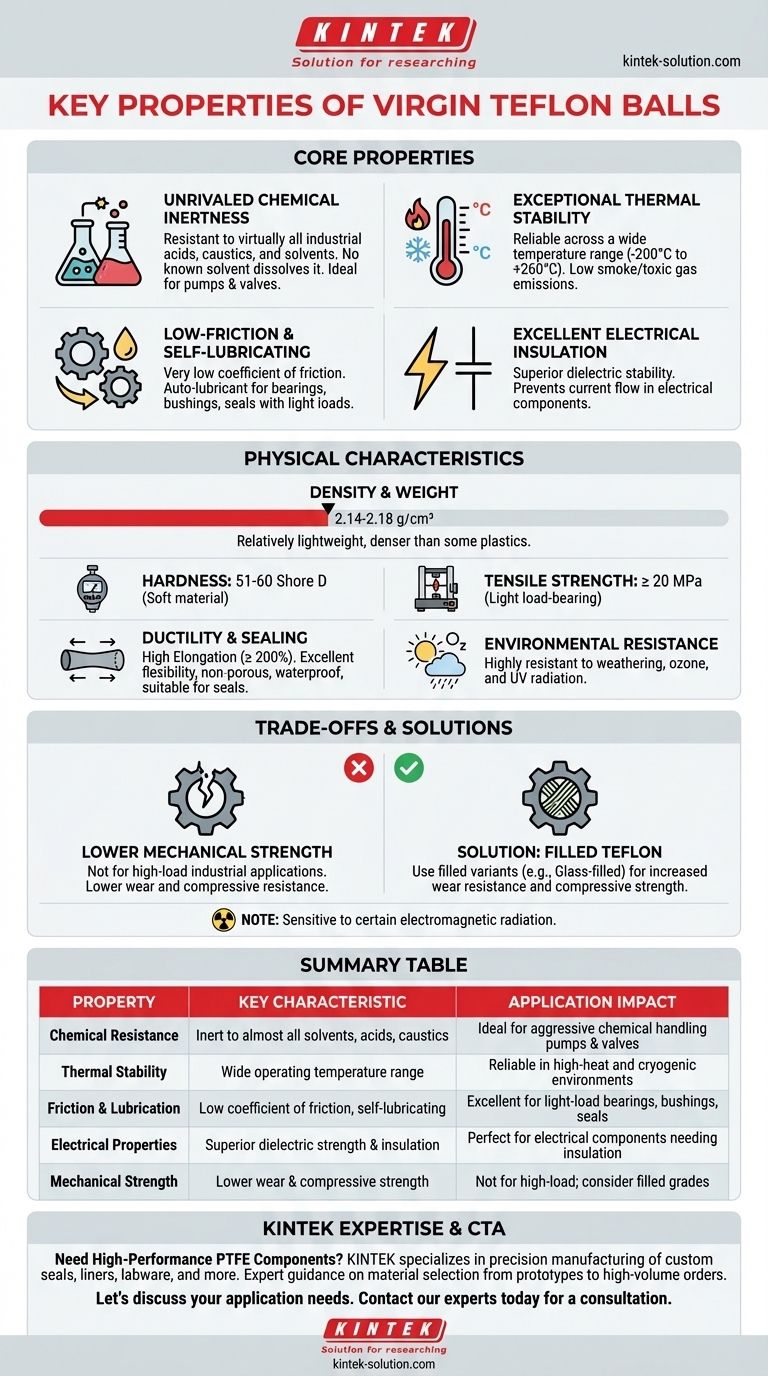

Unpacking the Core Properties of Virgin Teflon

Virgin Teflon, or Polytetrafluoroethylene (PTFE), is a unique fluoropolymer known for a combination of properties that make it a problem-solver in demanding environments.

Unrivaled Chemical Inertness

Virgin Teflon is famous for its resistance to chemical attack. There is no known solvent that can dissolve it, and it stands up to virtually all industrial acids and caustics.

This makes it an ideal material for components in pumps and valves that handle aggressive or corrosive fluids.

Exceptional Thermal Stability

These balls perform reliably across a wide operating temperature range, handling both high heat and low-temperature flexibility better than many other materials.

They also feature low smoke and toxic gas emissions, adding a layer of safety in high-temperature applications.

Low-Friction and Self-Lubricating Nature

Teflon possesses a very low coefficient of friction, allowing it to function as a self-lubricating (auto-lubricant) material.

This is critical for applications involving moving parts with light loads, such as in bearings, bushings, and seals, where minimizing friction is essential.

Excellent Electrical Insulation

With very good dielectric stability, virgin Teflon is a superior electrical insulator. This property makes it a common choice for various electrical components where preventing current flow is necessary.

Analyzing the Physical Characteristics

Beyond its core chemical and thermal properties, the physical makeup of virgin Teflon dictates its use cases.

Density and Weight

Virgin Teflon has a density of 2.14-2.18 g/cm³, making it a relatively lightweight material compared to metals but denser than many other plastics.

Hardness and Tensile Strength

With a Shore D hardness of 51-60 and a tensile strength of ≥ 20 MPa, virgin Teflon is considered a soft material. This suits it for light load-bearing roles but not for high-stress mechanical parts.

Ductility and Sealing

Its high elongation at break (≥ 200%) signifies excellent ductility and flexibility. This, combined with its non-porous and waterproof nature, makes it an excellent material for seals.

Environmental Resistance

Teflon is highly resistant to environmental factors, including weathering, ozone, and UV radiation (though electromagnetic radiation can alter its properties over time).

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging Teflon's limitations is crucial for successful implementation.

Lower Mechanical Strength

The most significant trade-off for virgin Teflon is its lower mechanical and wear resistance compared to other engineering plastics. It is not suitable for high-load industrial applications where compressive strength is key.

Virgin vs. Filled Teflon

To overcome this weakness, "filled" versions of Teflon exist. For example, glass-filled Teflon incorporates glass fibers to significantly increase wear resistance and compressive strength, making it better for high-load industrial or petrochemical use.

Sensitivity to Radiation

It is important to note that exposure to certain electromagnetic radiation can alter the properties of virgin Teflon, which may be a consideration in specific environments.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is handling aggressive chemicals: Virgin Teflon's unparalleled chemical inertness makes it one of the best choices available.

- If your primary focus is electrical insulation: Its high dielectric stability makes it a reliable and effective insulator for electrical components.

- If your primary focus is a high-load mechanical part: Virgin Teflon is likely unsuitable; you should consider a glass-filled variant or a different engineering plastic.

- If your primary focus is creating a durable seal: Its flexibility, chemical resistance, and wide temperature range make it an excellent candidate for demanding sealing applications.

Ultimately, choosing virgin Teflon is about leveraging its world-class chemical and thermal properties for applications that do not demand high mechanical strength.

Summary Table:

| Property | Key Characteristic | Application Impact |

|---|---|---|

| Chemical Resistance | Inert to virtually all solvents, acids, and caustics | Ideal for pumps and valves handling corrosive fluids |

| Thermal Stability | Wide operating temperature range | Reliable performance in high-heat and cryogenic environments |

| Friction & Lubrication | Low coefficient of friction, self-lubricating | Excellent for bearings, bushings, and seals with light loads |

| Electrical Properties | Superior dielectric strength and insulation | Perfect for electrical components requiring insulation |

| Mechanical Strength | Lower wear resistance and compressive strength | Not suitable for high-load applications; consider filled grades |

Need High-Performance PTFE Components?

Virgin Teflon's unique properties make it the ideal material for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. However, selecting the right grade—whether virgin or a filled variant like glass-filled PTFE for enhanced strength—is critical to your project's success.

KINTEK specializes in the precision manufacturing of PTFE components, including custom seals, liners, labware, and more. We offer expert guidance on material selection and provide custom fabrication from prototypes to high-volume orders, ensuring you get a solution perfectly tailored to your specific chemical, thermal, and mechanical requirements.

Let's discuss your application needs. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What materials can PTFE O-rings be produced with? From Virgin PTFE to Enhanced Compounds

- What are the extreme working conditions that PTFE Lip Seals can withstand? Handle -60°C to 200°C & 60 m/s

- What cooling and lubrication techniques are recommended for PTFE machining? Master Heat Control for Precision Parts

- What are the three primary application areas for PTFE O-rings? Master Sealing in Harsh Environments

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What are the disadvantages of PTFE bushings? Key Limitations for Engineers

- What types of PTFE seals are used in the medical field? From O-rings to Spring-Energized Seals