The primary durability limitations of PTFE impellers are their susceptibility to mechanical wear from high-speed mixing or abrasive materials and a strict operational temperature ceiling. While exceptionally resistant to chemicals, PTFE is a softer material than metal and will degrade under high physical stress or heat that a stainless steel equivalent could easily withstand.

While PTFE offers unparalleled chemical resistance and non-stick properties, it is not as mechanically robust or heat-tolerant as materials like stainless steel. The decision to use PTFE hinges on whether your application prioritizes chemical inertness over high-speed physical resilience.

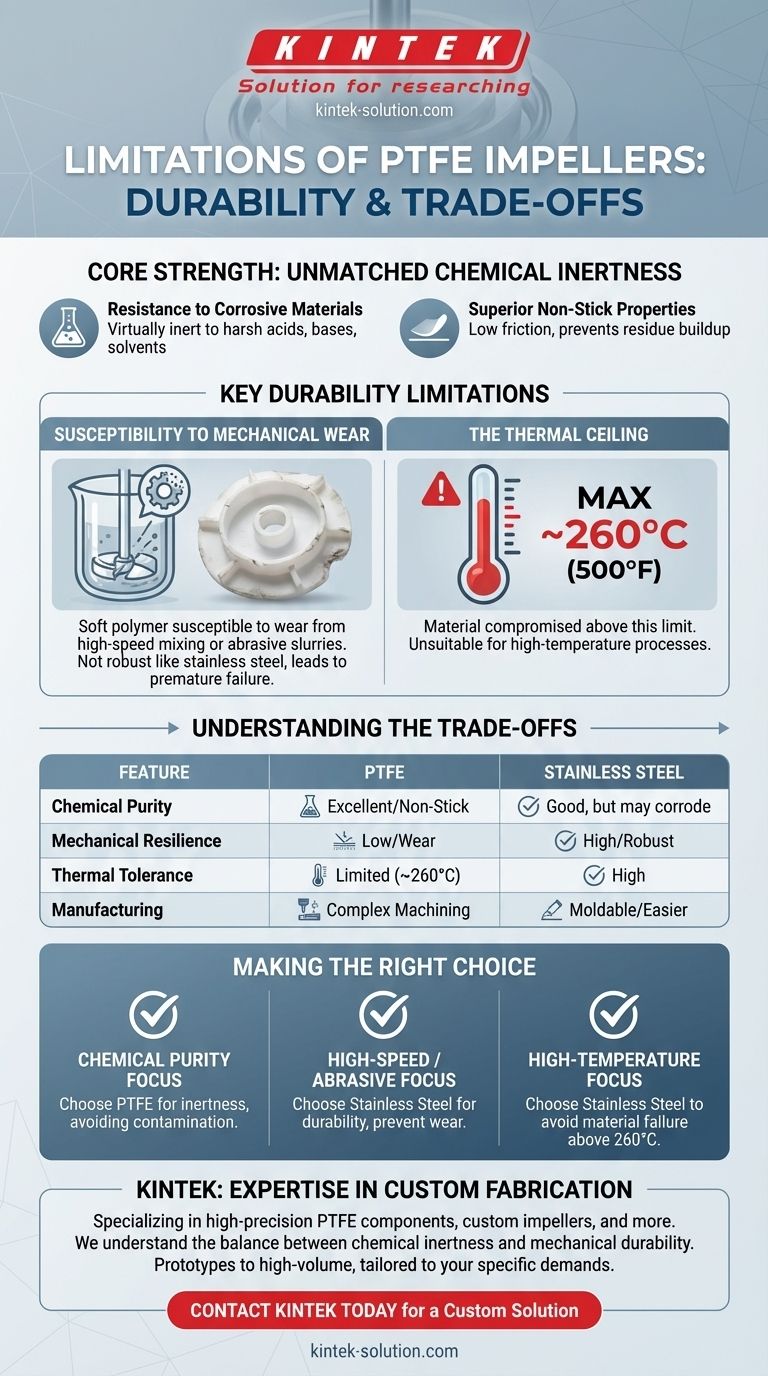

The Core Strength: Unmatched Chemical Inertness

Before examining its limitations, it's crucial to understand why PTFE is chosen in the first place. Its value lies in properties that other materials cannot match.

Resistance to Corrosive Materials

PTFE is virtually inert to almost all chemicals. This makes it the ideal choice for applications involving harsh acids, bases, and aggressive organic solvents where metal would corrode.

Superior Non-Stick Properties

The material has an extremely low coefficient of friction and excellent non-stick properties. This prevents residue buildup, making it perfect for working with sticky substances like adhesives or polymers and ensuring a high degree of cleanliness.

Key Durability Limitations Explained

The weaknesses of PTFE become apparent when mechanical and thermal demands increase.

Susceptibility to Mechanical Wear

PTFE is a relatively soft polymer. It is not as robust as stainless steel and can be susceptible to significant wear and tear over time, especially in demanding conditions.

High-speed mixing applications or processes involving abrasive slurries can cause the impeller to wear down, lose its shape, and ultimately fail.

The Thermal Ceiling

PTFE has a definitive upper temperature limit. The material begins to be compromised at approximately 260°C (500°F).

Applications that approach or exceed this temperature require a material with a much higher melting point, such as stainless steel.

Understanding the Trade-offs

Choosing an impeller material is always a matter of balancing competing requirements.

PTFE vs. Stainless Steel

The distinction is clear. PTFE is the specialist for chemical purity and non-stick applications. Stainless steel is the workhorse for high-strength, high-speed, and high-temperature applications.

Manufacturing Complexity

PTFE cannot be molded like other plastics. Each impeller must be individually machined from a solid block of material, a time-consuming and expensive process that requires specialized equipment and expertise.

Environmental Stability

In its favor, PTFE is highly resistant to environmental factors. It does not degrade or become brittle from exposure to UV light or oxidation, making it suitable for long-term applications where these are a concern.

Making the Right Choice for Your Application

Use your specific operational demands to guide your decision.

- If your primary focus is chemical purity and avoiding contamination: PTFE is the definitive choice due to its inert and non-stick nature.

- If your primary focus is high-speed mixing or processing abrasive slurries: Stainless steel is the more durable and reliable option to prevent premature wear.

- If your application involves temperatures approaching 260°C (500°F): You must choose an alternative like stainless steel to avoid material failure.

Ultimately, selecting the right impeller material requires a clear understanding of your process's unique chemical, thermal, and mechanical demands.

Summary Table:

| Limitation | Description | Key Consideration |

|---|---|---|

| Mechanical Wear | Soft polymer susceptible to wear from high-speed mixing or abrasive materials. | Not suitable for high-stress applications; stainless steel is more robust. |

| Thermal Ceiling | Maximum operating temperature of ~260°C (500°F). | Unsuitable for high-temperature processes; requires alternative materials. |

| Manufacturing | Must be machined from solid blocks, not molded. | Results in a more complex and expensive production process. |

Struggling to choose the right impeller material for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom impellers, for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between chemical inertness and mechanical durability.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your specific chemical, thermal, and mechanical requirements. Don't let material limitations compromise your process.

Contact KINTEK today to discuss your application and receive a custom solution that delivers both performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability