While often overlooked, washers are not mere accessories. They are critical engineering components that perform three primary functions in a mechanical assembly: distributing the load of a threaded fastener, acting as a spacer or isolator between components, and helping to prevent the assembly from loosening due to vibration.

A washer's true purpose isn't just to sit under a bolt head; it is to control the forces and stresses within a fastened joint, ensuring the assembly performs reliably and does not damage itself under load or over time.

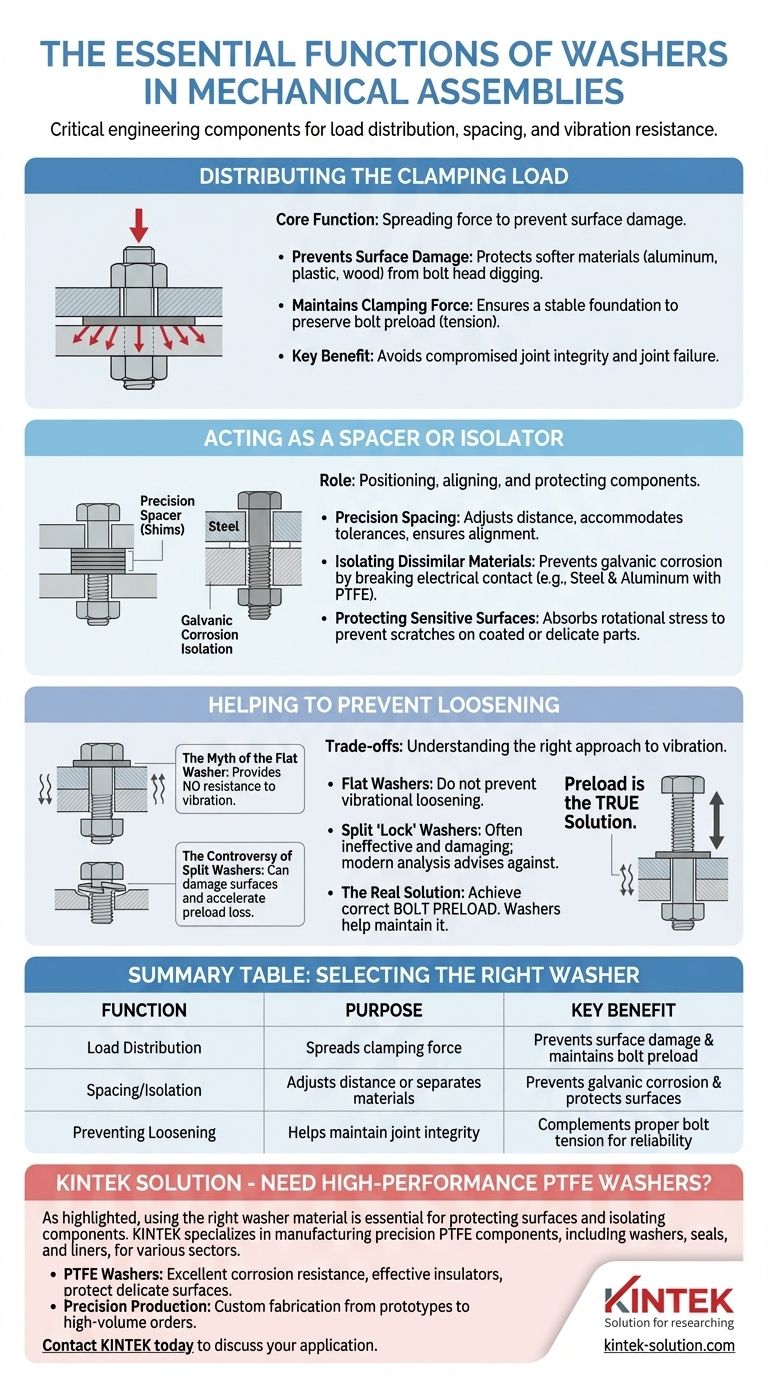

The Core Function: Distributing the Clamping Load

The most fundamental job of a standard flat washer is to act as a bridge for force. It takes the highly concentrated pressure from a bolt head or nut and spreads it over a wider surface area.

Why Load Distribution Matters

A tightened bolt creates an immense amount of clamping force in a very small area. Without a washer, this force can exceed the compressive strength of the material being fastened.

Preventing Surface Damage

This load distribution is especially critical when fastening into softer materials like aluminum, plastic, or wood. A washer prevents the bolt head from digging into and damaging the surface, which could compromise the joint's integrity.

Maintaining Clamping Force

If the surface material is damaged or deforms under the fastener's load, the bolt will lose its tension (known as preload). Since this tension is what holds the joint together, a loss of preload means a failed joint. A washer ensures a stable foundation to maintain this critical force.

The Role of Spacing and Isolation

Beyond managing loads, washers serve essential roles in positioning and protecting components within an assembly.

Acting as a Precision Spacer

In many designs, washers are used as shims or spacers. They can precisely adjust the distance between components, accommodate for variations in manufacturing tolerances, or ensure proper alignment.

Isolating Dissimilar Materials

When two different metals are in direct contact (e.g., a steel bolt on an aluminum panel), an electrical current can form, leading to galvanic corrosion. A non-conductive washer made from nylon or PTFE can act as a barrier, isolating the materials and preventing this destructive process.

Protecting Sensitive Surfaces

When a bolt or nut is tightened, its surface grinds against the component. A washer made of a softer material, like PTFE, absorbs this rotational stress. This protects painted, coated, or delicate surfaces from being scratched or damaged during assembly.

Understanding the Trade-offs and Misconceptions

While essential, the function of washers is often misunderstood, leading to incorrect application. The type of washer used must match the specific problem you are trying to solve.

The Myth of the Flat Washer

A standard flat washer does an excellent job of distributing load. However, it provides absolutely no resistance to loosening caused by vibration. It simply provides a smooth, stable surface for the fastener.

The Controversy of Split "Lock" Washers

Traditional split-ring "lock" washers are designed to dig into the bolt and the joint surface to resist loosening. However, modern engineering analysis has shown them to be largely ineffective. By digging in, they can damage the surface, leading to a faster loss of preload—the very problem they are meant to solve.

Preload is the True Solution

The most effective way to prevent a bolted joint from loosening is to achieve the correct bolt preload. Proper tension makes the joint so rigid that vibration cannot create the microscopic slips that lead to loosening. Washers are a tool to help achieve and maintain that preload, not a substitute for it.

How to Select the Right Washer

Your choice should be dictated by the primary goal you need to achieve for the joint.

- If your primary focus is protecting a soft material or spanning an oversized hole: Use a standard flat washer to effectively distribute the clamping load.

- If your primary focus is preventing vibrational loosening: Ensure you achieve proper bolt preload first, and consider modern locking methods like wedge-locking washers or chemical thread-lockers.

- If your primary focus is isolating materials or protecting a finished surface: Use a washer made from a non-abrasive, non-conductive material like nylon or PTFE.

By understanding these core functions, you can select the right washer to transform a simple connection into a robust and reliable mechanical assembly.

Summary Table:

| Function | Purpose | Key Benefit |

|---|---|---|

| Load Distribution | Spreads clamping force over a wider area | Prevents surface damage & maintains bolt preload |

| Spacing/Isolation | Adjusts distance or separates materials | Prevents galvanic corrosion & protects surfaces |

| Preventing Loosening | Helps maintain joint integrity under vibration | Complements proper bolt tension for reliability |

Need high-performance, non-abrasive washers for your critical assemblies?

As highlighted in this article, using the right washer material is essential for protecting surfaces and isolating components. KINTEK specializes in manufacturing precision PTFE components, including washers, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors.

Our PTFE washers provide excellent corrosion resistance, act as effective insulators, and protect delicate surfaces from damage during assembly and operation.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your application and request a quote for reliable PTFE washers that ensure your mechanical assemblies perform flawlessly.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications