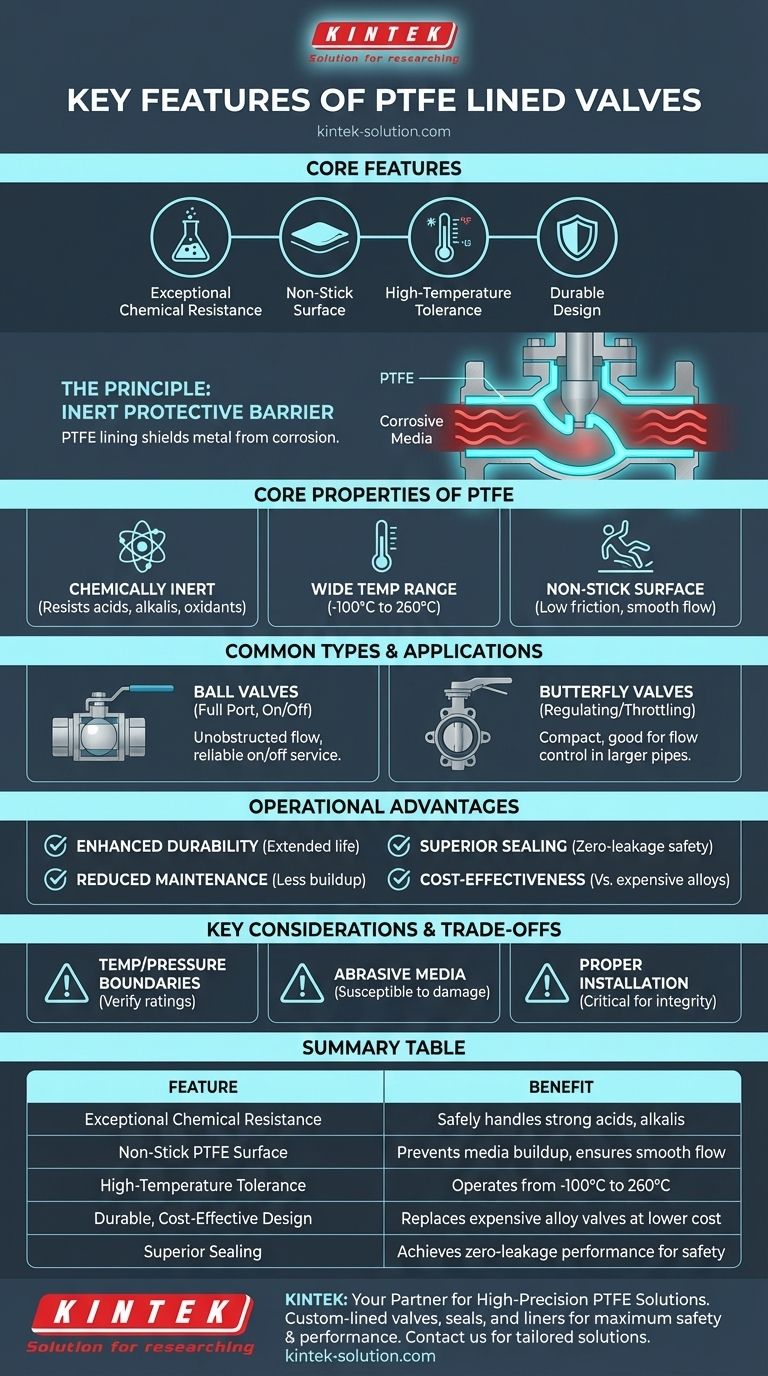

At their core, PTFE lined valves are defined by four key features: exceptional chemical resistance, a non-stick surface that prevents buildup, high-temperature tolerance, and a durable design that ensures operational safety and longevity. These characteristics make them a critical component for handling corrosive or aggressive fluids.

The fundamental purpose of a PTFE lined valve is to isolate its structural metal components from corrosive process media. By creating a chemically inert barrier, it delivers the performance of an expensive alloy valve at a significantly lower cost, while ensuring system integrity and safety.

The Principle: An Inert Protective Barrier

The primary function of the lining is to protect the valve's core structure, which is typically made from robust and affordable metals like ductile iron or carbon steel.

How PTFE Lining Works

A thick, uniform layer of Polytetrafluoroethylene (PTFE) is applied to all internal surfaces of the valve that come into contact with the fluid. This lining creates a seamless, non-reactive barrier.

This design ensures the corrosive media only ever touches the PTFE, completely protecting the structural metal body from chemical attack, corrosion, and abrasion.

Core Properties of PTFE

PTFE's unique molecular structure gives it several powerful advantages.

It is chemically inert to nearly all industrial chemicals, including strong acids, alkalis, and oxidants. It also features a wide operating temperature range, typically from -100°C up to 260°C.

Furthermore, its extremely low coefficient of friction creates a non-stick surface that prevents media from adhering to the valve's internals, ensuring smooth flow and easier operation.

Common Types and Their Applications

While the protective principle is the same, PTFE lined valves come in different designs tailored for specific operational needs.

PTFE Lined Ball Valves

These valves use a rotating ball with a bore through it. They are prized for their full port design, which means the opening is the same size as the pipe, offering virtually no restriction to flow when fully open.

Their construction often features a two-piece bolted body and easily replaceable seats, making them ideal for reliable on/off service where unobstructed flow is critical.

PTFE Lined Butterfly Valves

Butterfly valves control flow using a disc mounted on a rotating stem. They are lightweight, compact, and well-suited for both isolating (on/off) and regulating (throttling) flow.

Because of their simple, robust design, they are often used in larger diameter pipes for managing aggressive chemicals in applications from chemical processing to water treatment.

Understanding the Operational Advantages

The use of a PTFE lining translates directly into tangible benefits for performance, safety, and your bottom line.

Enhanced Durability and Longevity

By shielding the valve's metal body from corrosion, the PTFE lining dramatically extends the service life of the valve, even in the harshest industrial environments.

Reduced Maintenance and Downtime

The non-stick properties of PTFE minimize scaling and buildup within the valve, reducing the need for frequent cleaning. This, combined with their robust construction, lowers overall maintenance requirements.

Superior Sealing and Safety

PTFE lined valves are engineered to provide a tight shutoff, often achieving zero-leakage performance. This is a critical safety feature when managing hazardous or valuable fluids. The lining itself is often designed to resist blowout or collapse under pressure and vacuum conditions.

Significant Cost-Effectiveness

For many applications, a PTFE-lined carbon steel valve can provide the same or better chemical resistance as a valve constructed entirely from an expensive specialty alloy like Hastelloy, but at a fraction of the cost.

Key Considerations and Trade-offs

While highly effective, PTFE lined valves have operational limits that must be respected to ensure proper performance and safety.

Temperature and Pressure Boundaries

PTFE has distinct temperature and pressure limits. Exceeding these can compromise the integrity of the lining, potentially causing it to deform or fail. Always verify the valve's rating against your specific process conditions.

Susceptibility to Abrasive Media

While durable, the PTFE liner can be damaged by sharp, abrasive solids within the fluid. For highly abrasive slurries, a different valve type or a more specialized lining material may be a better choice.

Proper Installation is Critical

The integrity of the lining is paramount. Improper handling during installation, such as scratching the lining on the pipe flange, can create a failure point. Careful installation by trained personnel is essential for long-term reliability.

Making the Right Choice for Your System

Selecting the correct valve depends entirely on the operational goal within your fluid system.

- If your primary focus is on/off service with maximum flow: A PTFE lined ball valve is the ideal choice due to its unrestricted full-port design.

- If your primary focus is regulating or throttling flow, especially in larger pipes: A PTFE lined butterfly valve provides excellent control, a compact footprint, and cost-effectiveness.

- If your primary focus is safe containment of highly corrosive media: The superior sealing and chemically inert nature of any PTFE lined valve makes it a top-tier solution.

Ultimately, a properly specified PTFE lined valve is a robust, reliable, and economical solution for safely managing the most demanding fluids in your process.

Summary Table:

| Feature | Benefit |

|---|---|

| Exceptional Chemical Resistance | Safely handles strong acids, alkalis, and oxidants |

| Non-Stick PTFE Surface | Prevents media buildup, ensures smooth flow |

| High-Temperature Tolerance | Operates from -100°C to 260°C |

| Durable, Cost-Effective Design | Replaces expensive alloy valves at lower cost |

| Superior Sealing | Achieves zero-leakage performance for safety |

Need a reliable, cost-effective solution for handling corrosive fluids? KINTEK specializes in manufacturing high-precision PTFE components, including custom-lined valves, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems achieve maximum safety, longevity, and performance. Contact us today to discuss your specific requirements—from prototypes to high-volume orders—and let us deliver a tailored PTFE solution that protects your process and your budget.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when designing a PTFE PCB? Master High-Frequency Performance

- What are some main applications of PTFE as a wear resistant material? Extend Machinery Life with Low-Friction Components

- What industries commonly use PTFE lined dual plate check valves? Essential for Corrosive & High-Purity Applications

- Why is lubrication important in PTFE machining? Master Heat Control for Precision Parts

- What are the different types of Teflon gland packing available? Select the Right PTFE Seal for Your Application

- What makes Medical Grade PTFE Liners durable? Unmatched Chemical & Physical Resilience

- How do PTFE valves compare with PFA valves? A Guide to Superior Chemical Resistance & Durability

- Why are PTFE spring-energized seals ideal for semiconductor manufacturing? Ensure Purity and Maximize Yield