The primary advantages of using PTFE in electric actuated butterfly valves are its exceptional chemical resistance, broad temperature tolerance, and extremely low friction. These properties work together to ensure the valve not only survives in demanding environments but also enhances the long-term performance and reliability of the electric actuator controlling it.

The core reason to specify PTFE in an electric butterfly valve goes beyond simple material resistance. Its low-friction nature directly reduces the mechanical stress and energy required by the electric actuator, leading to a more efficient, reliable, and durable automated system.

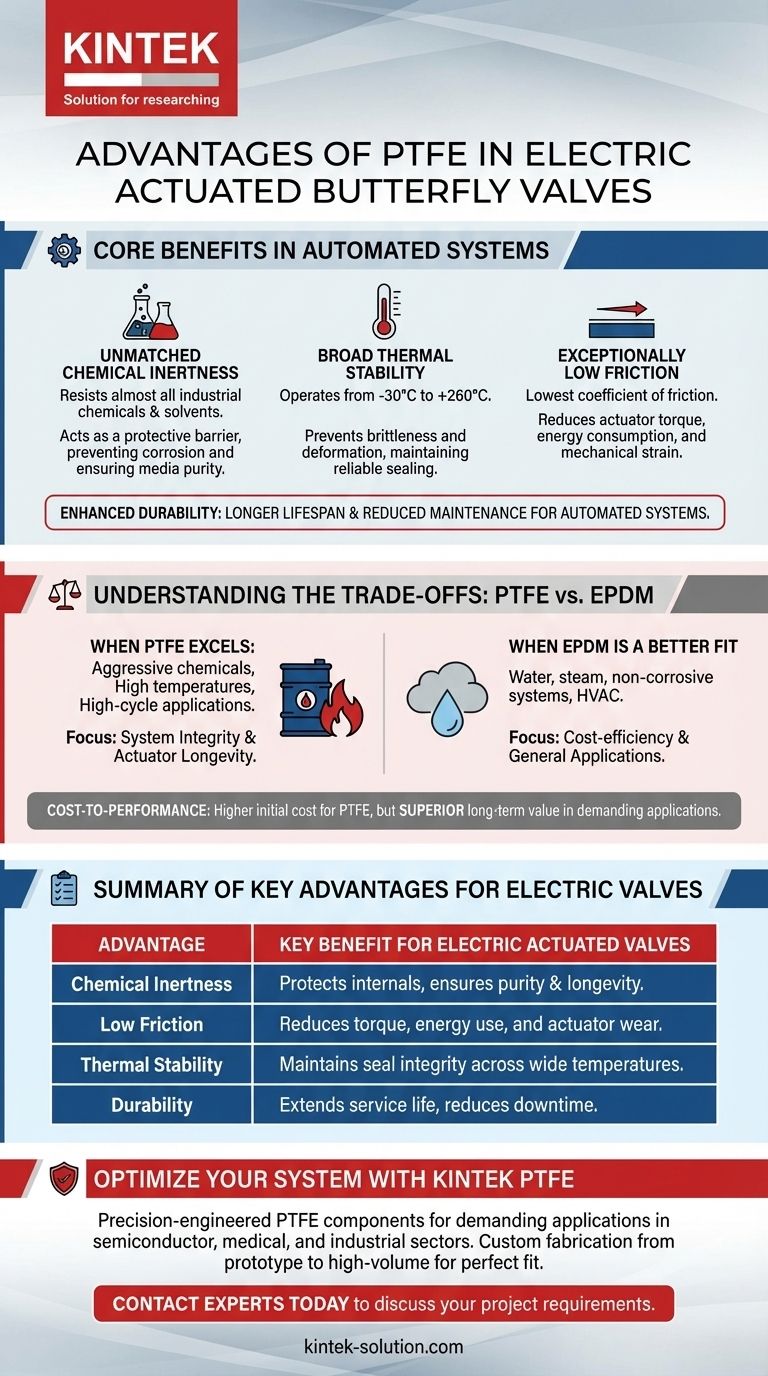

The Core Benefits of PTFE in Automated Systems

When a butterfly valve is paired with an electric actuator, the properties of the valve seat have a direct impact on the entire automated assembly. PTFE (Polytetrafluoroethylene) offers a unique combination of characteristics that are highly synergistic with electric actuation.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an essential choice for applications involving aggressive or corrosive media.

A PTFE seat or lining acts as a protective barrier, isolating the valve's metal body and disc from chemical attack. This prevents corrosion, extends the valve's service life, and ensures the purity of the media flowing through it.

Broad Thermal Stability

PTFE maintains its integrity across an exceptionally wide temperature range, typically from -30°C to +200°C (-22°F to 392°F), with some grades withstanding continuous temperatures up to +260°C (500°F).

This thermal stability prevents the seat from becoming brittle at low temperatures or deforming under high heat. For an automated valve, this consistency is critical for maintaining a reliable seal cycle after cycle without failure.

Exceptionally Low Friction

PTFE has the lowest coefficient of friction of any solid material. This is arguably its most significant advantage in the context of an electric actuated valve.

Opening and closing a butterfly valve requires the disc to turn against the seat. Lower friction means less torque is needed from the actuator to perform this action. This reduced torque demand translates to less strain on the actuator's motor and gears, lower energy consumption, and smoother, more consistent operation.

Enhanced Durability and Lifespan

The combination of chemical, thermal, and wear resistance results in a valve with a significantly longer lifespan. A durable PTFE seat reduces the frequency of maintenance and replacement, which is a major benefit in automated systems where downtime is costly.

Understanding the Trade-offs: PTFE vs. EPDM

While PTFE offers superior performance in many areas, it is not the universal solution for every application. Understanding its characteristics relative to other common materials like EPDM is key to making an informed decision.

When PTFE Excels

PTFE is the definitive choice for services involving harsh chemicals, solvents, acids, and bases. Its high-temperature tolerance also makes it indispensable for processes operating under extreme thermal conditions. Its low-friction properties make it ideal for high-cycle applications where actuator longevity is paramount.

When EPDM Is a Better Fit

EPDM (Ethylene Propylene Diene Monomer) offers excellent resistance to water, steam, and weathering. It is a highly durable and more flexible material, often providing a bubble-tight seal with less torque in less demanding applications. For water treatment, HVAC, and general industrial water lines, EPDM is typically the more cost-effective and suitable choice.

The Cost-to-Performance Ratio

PTFE components generally have a higher initial cost than EPDM. However, in applications where EPDM would quickly degrade, the superior longevity and reliability of PTFE provide a far better long-term price-to-performance ratio by minimizing downtime and replacement costs.

Making the Right Choice for Your Application

Selecting the correct seat material is crucial for optimizing the performance and lifespan of your electric actuated butterfly valve.

- If your primary focus is handling aggressive chemicals or high temperatures: PTFE is the definitive choice for ensuring system integrity and long-term reliability.

- If your primary focus is optimizing actuator performance and longevity: PTFE's low friction reduces motor strain, making it ideal for high-cycle automated applications.

- If your primary focus is cost-efficiency in water, steam, or non-corrosive systems: EPDM often provides excellent performance and is the more economical solution.

By matching the valve seat material to your specific operational demands, you ensure the efficiency and resilience of your entire automated process.

Summary Table:

| Advantage | Key Benefit for Electric Actuated Valves |

|---|---|

| Chemical Inertness | Protects valve internals from corrosive media, ensuring system purity and longevity. |

| Low Friction | Reduces actuator torque demand, lowering energy use and wear on motor/gears. |

| Thermal Stability | Maintains seal integrity across a wide temperature range (-30°C to +260°C). |

| Durability | Extends service life and reduces maintenance downtime in demanding applications. |

Optimize your automated valve system with precision-engineered PTFE components from KINTEK.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, the right PTFE seal, liner, or custom component is critical for performance and reliability. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures a perfect fit for your specific needs, enhancing actuator efficiency and system uptime.

Contact our experts today to discuss your project requirements and discover the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers