In industrial settings, the value of a component is measured by its reliability and efficiency. The practical benefits of using Polytetrafluoroethylene (PTFE) components are significant, primarily stemming from a unique combination of material properties. These advantages translate directly into lower maintenance costs, enhanced performance in extreme conditions, and improved operational safety, driven by its profound chemical resistance, low friction, and thermal stability.

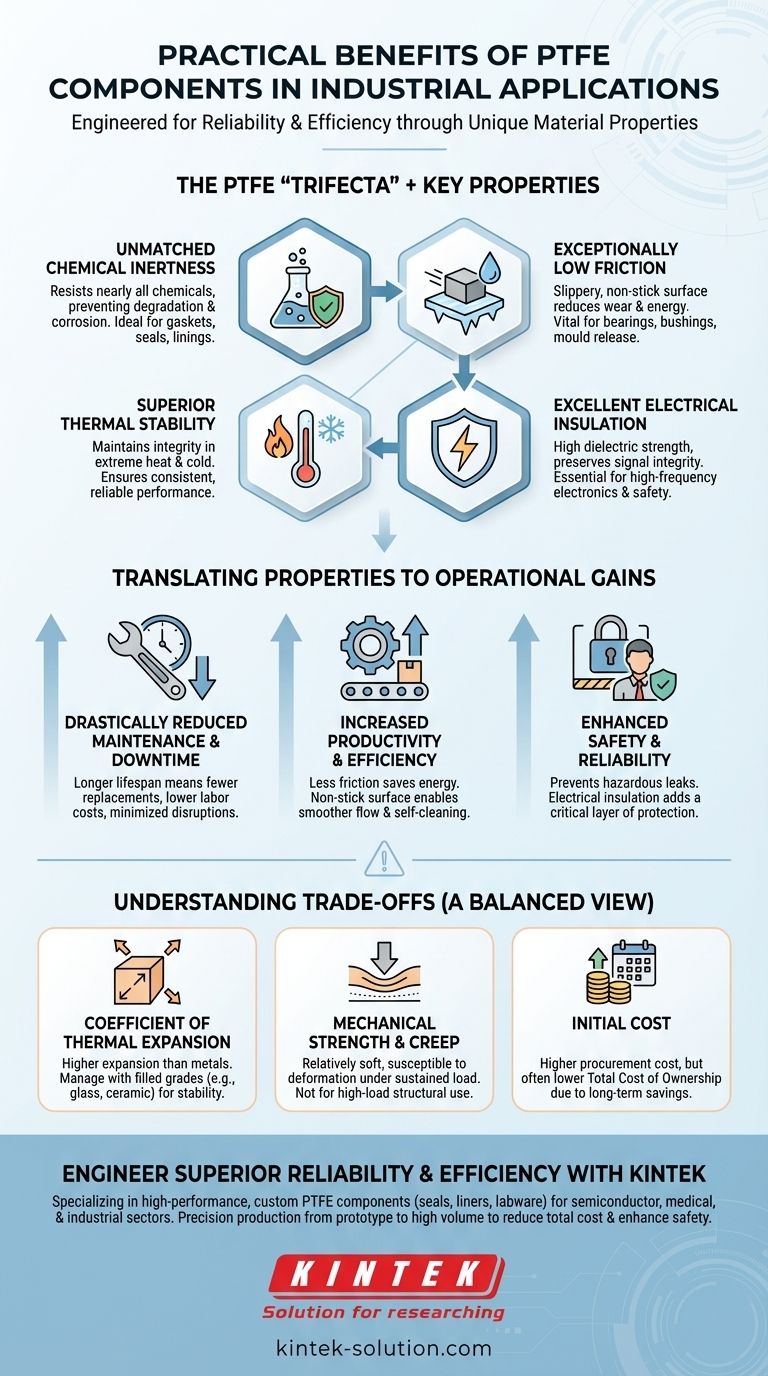

The core value of PTFE is not a single feature, but its powerful combination of chemical inertness, non-stick surface, and wide temperature tolerance. This trifecta makes it a premier problem-solving material for the most demanding industrial environments where other materials would quickly fail.

The Core Properties Driving PTFE's Value

To understand the benefits of PTFE, we must first look at its fundamental characteristics. These intrinsic properties are the source of its power and versatility in industrial applications.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and bases. This chemical standoffishness prevents it from degrading, corroding, or reacting with the substances it contains or contacts.

This makes it an ideal material for gaskets, seals, and linings in chemical processing plants, where it ensures containment integrity and prevents costly and dangerous leaks.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, creating an incredibly slippery, non-stick surface. This property is akin to the minimal resistance you'd feel sliding ice on ice.

This characteristic is critical for applications like self-lubricating bearings and bushings, where it reduces wear and energy consumption. It's also vital for non-stick surfaces in food processing and mould release applications, ensuring materials move smoothly without adhesion.

Superior Thermal Stability

PTFE components maintain their structural integrity and performance across an exceptionally wide range of temperatures. They can operate effectively in extreme heat, such as automotive engine compartments, as well as in cryogenic applications.

This resilience ensures that seals do not become brittle in the cold or degrade under high heat, providing consistent and reliable performance where other polymers would fail.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. It resists the flow of electricity and maintains its insulating properties consistently, even at high frequencies.

This makes it essential for high-speed and high-frequency electronics, such as microwave and RF components, where it preserves signal integrity. It also enhances safety in equipment that operates in potentially explosive atmospheres.

Translating Properties into Operational Gains

These core properties deliver tangible, real-world benefits that impact an organization's bottom line and operational resilience.

Drastically Reduced Maintenance and Downtime

Because PTFE components do not easily corrode, wear out from friction, or degrade from heat, they have a significantly longer lifespan.

This inherent durability means less frequent need for replacements, which directly translates to reduced maintenance labor, minimized industrial downtime, and lower long-term operational costs.

Increased Productivity and Efficiency

In mechanical systems, less friction means less energy is wasted. In automotive applications, PTFE seals and bushings reduce friction, which can improve fuel economy. In manufacturing, its non-stick surface allows conveyor systems and production lines to run more smoothly.

Furthermore, the non-wetting property of PTFE can promote self-cleaning, preventing buildup that might otherwise halt production for maintenance.

Enhanced Safety and Reliability

The chemical inertness of PTFE gaskets and pipe linings prevents the leakage of hazardous materials, protecting both personnel and the environment.

Its role as a superior electrical insulator adds a critical layer of safety, preventing electrical shorts and failures, especially when handling conductive fluids or operating in volatile environments.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging PTFE's limitations to ensure proper application.

Coefficient of Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more significantly with temperature changes, which must be accounted for in design to avoid stress and failure.

This effect is often managed by using filled grades of PTFE, where additives like woven glass or ceramic fillers are introduced to improve dimensional stability.

Mechanical Strength and Creep

Compared to metals and some engineering plastics, PTFE is a relatively soft material. It can be susceptible to "creep," which is a slow deformation under a sustained load.

For this reason, pure PTFE is not typically used for high-load structural components unless it is reinforced or used as a coating or liner.

Initial Cost

The initial procurement cost of PTFE components can be higher than that of more conventional materials.

However, this initial investment is often justified by a lower total cost of ownership. The savings from reduced maintenance, longer component life, and decreased downtime frequently outweigh the higher upfront material cost.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is reliability in harsh chemical environments: PTFE's unrivaled chemical inertness makes it the definitive choice for gaskets, seals, and linings that will not degrade.

- If your primary focus is reducing energy loss and wear: Its extremely low friction is ideal for creating self-lubricating bearings, wear-resistant coatings, and non-stick surfaces.

- If your primary focus is high-frequency electronics: PTFE's stable dielectric properties are essential for ensuring signal integrity in microwave and RF components.

- If your primary focus is operational safety: Its combination of electrical insulation and chemical containment provides a critical and reliable layer of protection for both equipment and personnel.

Ultimately, selecting PTFE is a strategic decision to engineer superior reliability and efficiency directly into your most demanding industrial systems.

Summary Table:

| Key Property | Primary Industrial Benefit |

|---|---|

| Chemical Inertness | Prevents corrosion & leaks in chemical processing, ensuring safety and containment integrity. |

| Low Friction | Reduces wear and energy consumption in bearings and bushings; enables non-stick surfaces. |

| Thermal Stability | Maintains performance in extreme heat or cold, providing reliable seals and components. |

| Electrical Insulation | Ensures signal integrity in high-frequency electronics and enhances operational safety. |

Ready to engineer superior reliability and efficiency into your systems?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, are designed to solve your most demanding application challenges, reduce your total cost of ownership, and enhance operational safety.

Contact KINTEK today to discuss your specific needs and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments