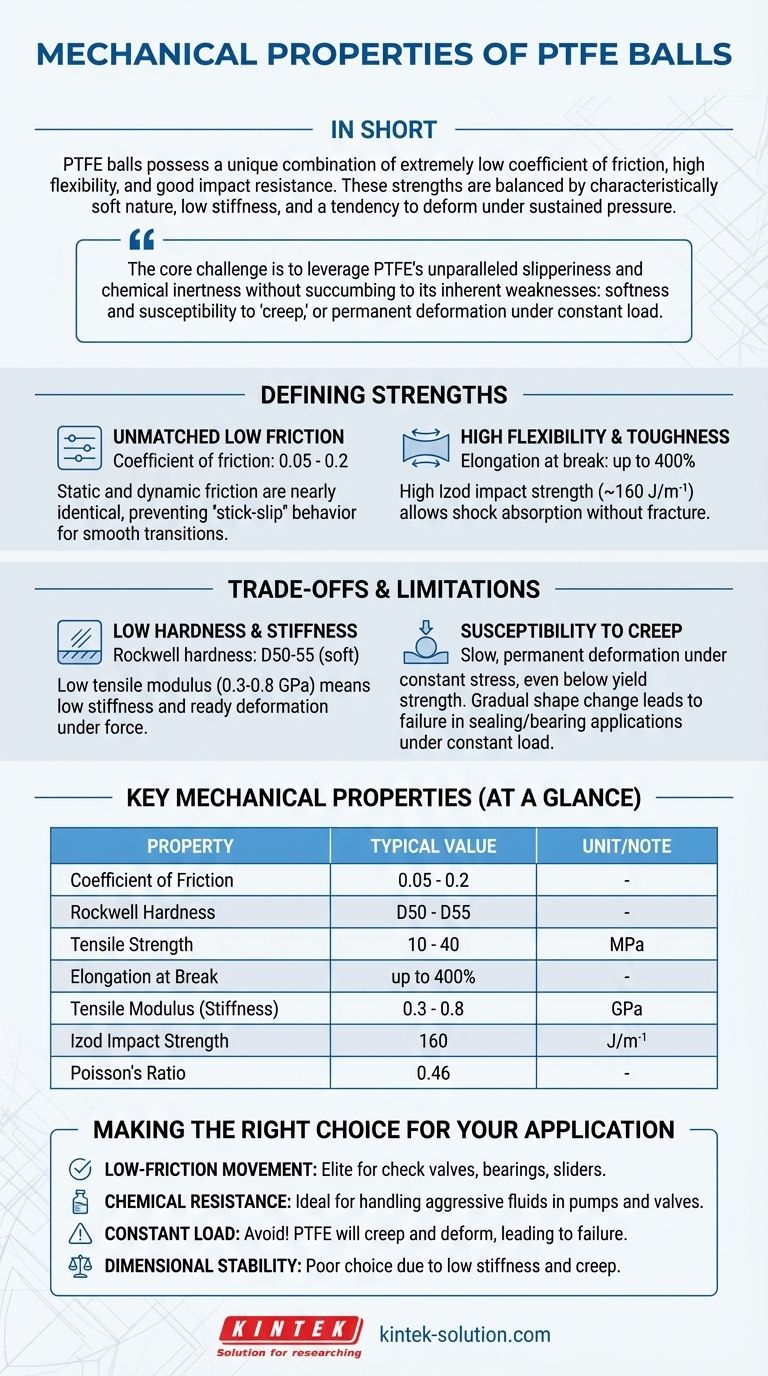

In short, PTFE balls possess a unique combination of mechanical properties defined by an extremely low coefficient of friction, high flexibility, and good impact resistance. However, these strengths are balanced by a characteristically soft nature, low stiffness, and a tendency to deform under sustained pressure. Key metrics include a Rockwell hardness of D50-55, a tensile strength of 10-40 MPa, and an exceptional elongation at break of up to 400%.

The core challenge when using PTFE balls is to leverage their unparalleled slipperiness and chemical inertness without succumbing to their inherent weaknesses: softness and a susceptibility to "creep," or permanent deformation under a constant load.

The Defining Strengths of PTFE

PTFE's mechanical behavior makes it an exceptional material for specific, targeted applications. Its primary advantages are not in strength but in its unique surface and flexibility characteristics.

Unmatched Low Friction

The most famous property of PTFE is its exceptionally low coefficient of friction, typically measured between 0.05 and 0.2.

Critically, the static and dynamic friction coefficients are nearly identical. This prevents "stick-slip" behavior, ensuring a smooth transition from a standstill to motion, which is vital for precision instruments and check valves.

High Flexibility and Toughness

PTFE is not brittle. It exhibits a very high elongation at break of around 400%, meaning it can stretch to four times its original length before failing.

This flexibility, combined with a good Izod impact strength (around 160 J/m⁻¹), makes it a durable material that can absorb shocks and impacts without fracturing.

Understanding the Trade-offs and Limitations

To use PTFE effectively, you must understand its significant limitations. These properties make it unsuitable for applications requiring high structural integrity or dimensional stability under load.

Low Hardness and Stiffness

PTFE is a relatively soft material, with a Rockwell hardness of only D50-55. This makes it susceptible to scratches and surface damage.

Furthermore, it has a very low tensile modulus (0.3-0.8 GPa), meaning it is not very stiff. It will readily deform when a force is applied, rather than rigidly resisting it.

Susceptibility to Creep

The most significant mechanical weakness of PTFE is its tendency to creep. This is the term for slow, permanent deformation when the material is subjected to a constant stress, even if that stress is well below its yield strength.

This means that in applications with a constant load, a PTFE ball will gradually flatten or change shape over time, which can lead to failure in sealing or bearing applications.

Key Mechanical Properties (At a Glance)

For technical reference, here are the typical property values for PTFE. Note that exact figures can vary based on the specific grade and manufacturing process.

Friction and Hardness

- Coefficient of Friction: 0.05 - 0.2

- Rockwell Hardness: D50 - D55

Strength and Modulus

- Tensile Strength: 10 - 40 MPa

- Tensile Modulus (Stiffness): 0.3 - 0.8 GPa

- Izod Impact Strength: 160 J/m⁻¹

Deformation Properties

- Elongation at Break: up to 400%

- Poisson's Ratio: 0.46

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on its unique profile. Use this guide to determine if its properties align with your primary goal.

- If your primary focus is low-friction movement: PTFE is an elite choice for applications like check valves, bearings, and sliders where smooth, low-energy motion is the top priority.

- If your primary focus is chemical resistance: PTFE's inertness, combined with its mechanical properties, makes it ideal for handling aggressive fluids in pumps and valve systems.

- If your primary focus is carrying a significant, constant load: You must avoid using solid PTFE balls, as they will creep and deform, leading to eventual failure.

- If your primary focus is dimensional stability under pressure: PTFE is a poor choice due to its low stiffness and tendency to creep; consider a harder polymer or a metal instead.

Ultimately, understanding both the strengths and the significant limitations of PTFE is the key to successful engineering design.

Summary Table:

| Property | Typical Value |

|---|---|

| Coefficient of Friction | 0.05 - 0.2 |

| Rockwell Hardness | D50 - D55 |

| Tensile Strength | 10 - 40 MPa |

| Elongation at Break | up to 400% |

| Tensile Modulus (Stiffness) | 0.3 - 0.8 GPa |

| Izod Impact Strength | 160 J/m⁻¹ |

Need High-Performance PTFE Components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom balls—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance of PTFE's low friction and chemical inertness against its mechanical limitations. Our expertise ensures your parts are designed and fabricated to perform optimally in your specific application, from prototypes to high-volume production.

Contact us today to discuss your project requirements and leverage our material science expertise!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide