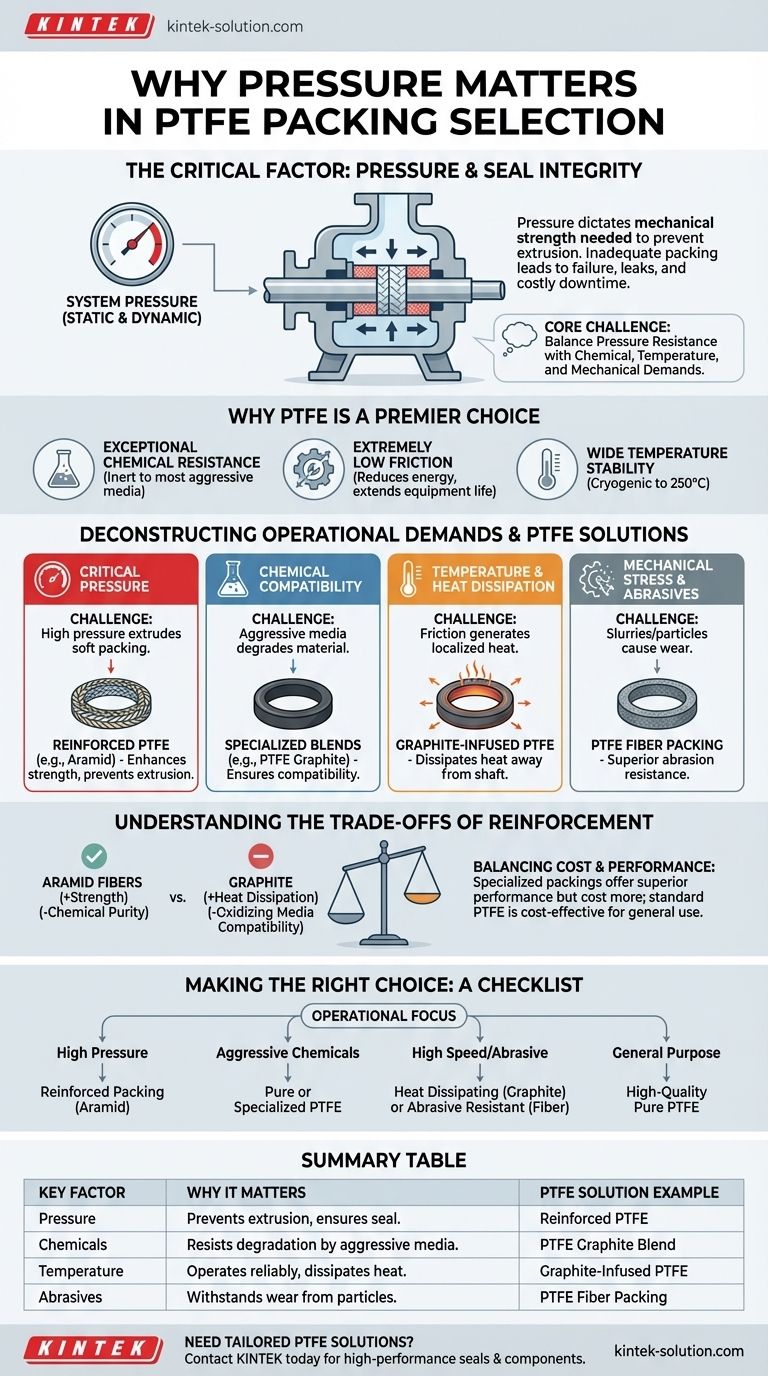

Pressure is a critical factor when choosing PTFE packing because it directly dictates the mechanical strength required to maintain a seal. If the packing material cannot withstand the system's static and dynamic pressures, it will physically extrude or fail, leading to leaks, equipment damage, and costly downtime. High-pressure applications demand packing that is reinforced to provide the necessary structural integrity.

The core challenge is not just to select packing that withstands pressure, but to choose a material that balances pressure resistance with chemical compatibility, temperature stability, and mechanical stress. An effective seal depends on a holistic evaluation of the entire operating environment.

Why PTFE Packing is a Premier Choice

Polytetrafluoroethylene (PTFE) is a leading material for industrial packing due to its unique combination of properties. Understanding these baseline advantages helps clarify why modifications for specific conditions are so important.

Exceptional Chemical Resistance

PTFE is one ofthe most chemically inert materials available. It does not react with the vast majority of industrial chemicals, acids, solvents, or bases, making it a reliable choice for aggressive media.

Extremely Low Friction

The material has an exceptionally low coefficient of friction. This reduces the energy needed to power equipment like pumps and minimizes wear on moving parts such as shafts, extending the service life of the machinery.

Wide Temperature Stability

PTFE performs reliably across an enormous temperature range, from cryogenic conditions up to 250°C (482°F). This versatility allows it to be used in both extreme cold and high-heat processes without degrading.

Deconstructing the Operational Demands

While pressure is the starting point of your question, it is one of several interconnected factors. A failure in any one area can compromise the entire sealing system.

The Critical Role of Pressure

You must determine both the static pressure (when the system is at rest) and the dynamic pressure (during operation). High pressures can physically force a softer packing material out of its housing.

To counteract this, reinforced PTFE packing is used. Blending PTFE with materials like aramid fibers creates a composite packing with significantly higher strength and durability, preventing extrusion under intense pressure.

Chemical Compatibility

While PTFE is highly resistant, no material is universally immune. You must evaluate the specific type and concentration of chemicals the packing will contact.

Certain aggressive substances may require specialized blends, such as PTFE graphite packing, to ensure complete compatibility and prevent degradation over time.

Temperature and Heat Dissipation

The operational temperature range must fall within the packing's limits. In high-speed applications, friction from a pump shaft can generate significant localized heat.

Packing materials infused with graphite, for example, are excellent at dissipating this heat away from the shaft, preventing overheating and premature packing failure.

Mechanical Stress and Abrasives

Consider the mechanical forces at play, such as the speed of a rotating shaft. Additionally, the media itself can be a source of stress.

If you are sealing a fluid containing abrasive particles, such as a slurry, a standard packing will wear out quickly. In these cases, PTFE fiber packing is often selected for its superior ability to handle abrasive media.

Understanding the Trade-offs of Reinforcement

Adding reinforcement fibers to PTFE is not a simple upgrade; it's a design choice with specific trade-offs. The goal is to enhance one property without unacceptably compromising another.

Strength vs. Chemical Purity

Adding aramid fibers dramatically increases pressure resistance and mechanical strength. However, aramid is not as chemically inert as pure PTFE, which may make it unsuitable for the most aggressive chemical applications.

Heat Dissipation vs. Media Type

Incorporating graphite significantly improves thermal conductivity, which is crucial for high-speed pumps. However, graphite may not be suitable for certain highly oxidizing media where pure PTFE would be required.

Balancing Cost and Performance

Specialized, reinforced packings offer superior performance in demanding conditions but come at a higher cost. For moderate, general-purpose applications, a standard pure PTFE packing is often the most cost-effective and reliable solution.

Making the Right Choice for Your Application

Selecting the correct packing requires matching the material's specifications to the precise demands of your system. Use your operational parameters as a checklist.

- If your primary focus is high-pressure sealing: Choose a reinforced packing, such as PTFE with aramid corner braids, to prevent extrusion.

- If your primary focus is aggressive chemical resistance: Start with pure PTFE packing, but verify compatibility or consider specialized grades for unique media.

- If your primary focus is high-speed or abrasive service: Select a packing designed for heat dissipation (like PTFE graphite) or abrasion resistance (like PTFE fiber).

- If your primary focus is general, multi-purpose use: A high-quality, pure PTFE packing provides a versatile and reliable seal for moderate conditions.

By systematically evaluating each operational factor, you can select a packing that ensures the safety, efficiency, and reliability of your equipment.

Summary Table:

| Key Factor | Why It Matters for PTFE Packing |

|---|---|

| Pressure | Determines required mechanical strength; high pressure demands reinforced packing to prevent extrusion. |

| Chemical Compatibility | PTFE is highly inert, but aggressive media may require specialized blends (e.g., PTFE graphite). |

| Temperature | PTFE operates from cryogenic to 250°C; heat dissipation (e.g., with graphite) is critical for high-speed applications. |

| Mechanical Stress/Abrasives | Abrasive media (e.g., slurries) require PTFE fiber packing for wear resistance and longevity. |

Need a PTFE packing solution tailored to your specific pressure, chemical, and temperature requirements? At KINTEK, we manufacture high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a packing that balances pressure resistance, chemical compatibility, and durability. Contact us today for a solution that guarantees reliability and efficiency in your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection