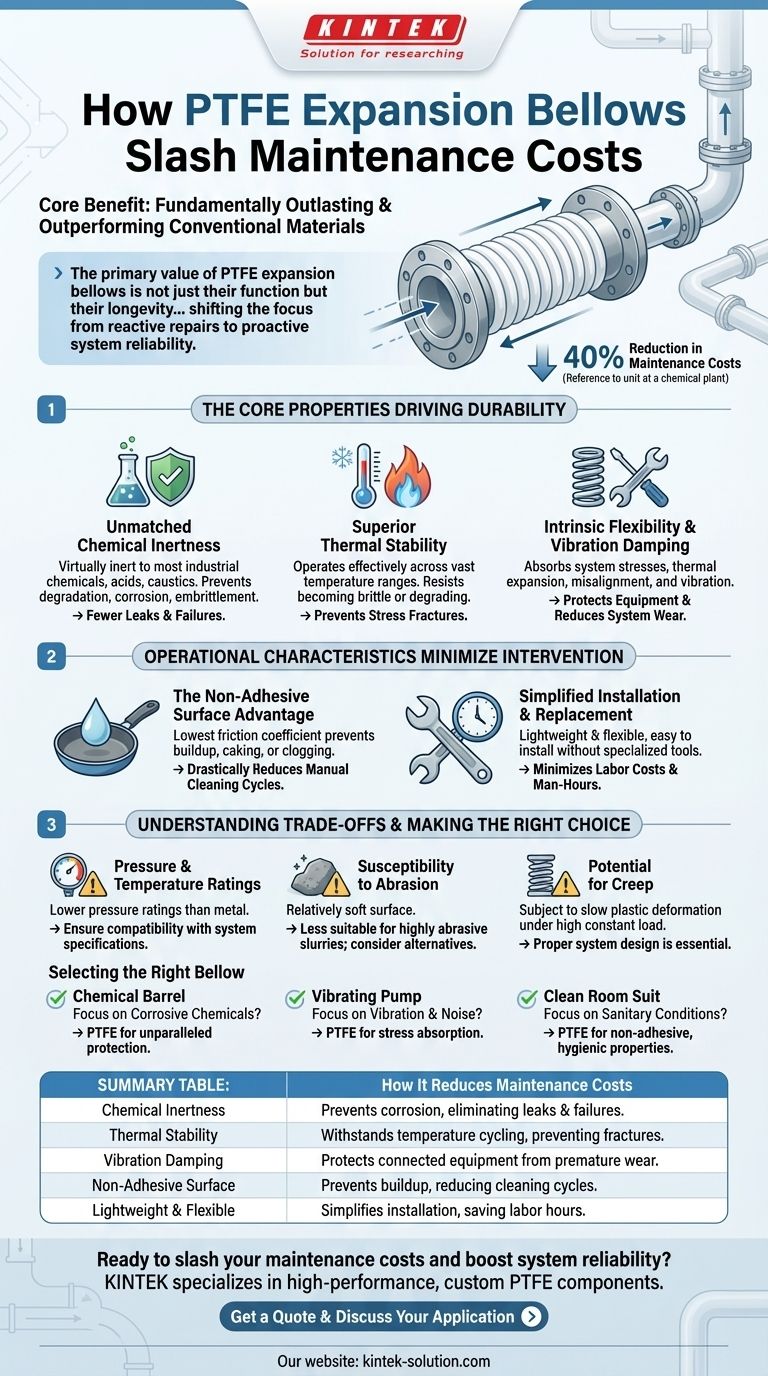

At its core, PTFE expansion bellows reduce maintenance costs by fundamentally outlasting and outperforming conventional materials in demanding operational environments. Their unique combination of chemical inertness, thermal stability, and physical resilience directly translates to fewer failures, less system downtime, and significantly lower long-term operational expenses. One chemical plant, for instance, reported a 40% reduction in maintenance costs after making the switch.

The primary value of PTFE expansion bellows is not just their function but their longevity. By resisting chemical attack, thermal stress, and physical vibration, they eliminate the root causes of frequent maintenance, shifting the focus from reactive repairs to proactive system reliability.

The Core Properties Driving Durability

The cost-saving benefits of PTFE bellows begin at the molecular level. The material's inherent characteristics create a component that is exceptionally resilient to the common causes of industrial wear and tear.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and caustics. This resistance prevents the material degradation, corrosion, and embrittlement that cause leaks and catastrophic failures in metal or rubber bellows.

By resisting chemical attack, the bellow maintains its structural integrity for a much longer operational life, eliminating the need for frequent inspection and replacement.

Superior Thermal Stability

These components operate effectively across a vast temperature range without losing their essential properties. They do not become brittle at low temperatures or degrade at high temperatures.

This thermal stability ensures reliable performance during temperature cycling, preventing stress fractures and failures that would otherwise require immediate and costly maintenance intervention.

Intrinsic Flexibility and Vibration Damping

PTFE expansion bellows are designed to absorb system stresses. They effectively accommodate thermal expansion and contraction, pipe misalignment, and mechanical vibration.

By isolating vibration, they protect more expensive downstream and upstream equipment, such as pumps and vessels, from premature wear and failure, reducing the maintenance burden on the entire system.

How Operational Characteristics Minimize Intervention

Beyond material toughness, the day-to-day operational characteristics of PTFE bellows are engineered to require minimal human intervention, saving labor hours and reducing downtime.

The Non-Adhesive Surface Advantage

PTFE has one of the lowest coefficients of friction of any solid, resulting in a non-stick surface. This non-adhesive property prevents process media from building up, caking, or clogging the bellow.

This self-cleaning characteristic is critical in industries from pharmaceuticals to chemical processing, as it drastically reduces the need for manual cleaning cycles and prevents costly blockages.

Simplified Installation and Replacement

Compared to their metal counterparts, PTFE expansion bellows are exceptionally lightweight and flexible. This makes them significantly easier and faster to install, often without requiring specialized tools or heavy lifting equipment.

While replacements are infrequent, this ease of installation minimizes the labor costs and man-hours associated with any necessary system work.

Understanding the Trade-offs

To make a fully informed decision, it is crucial to recognize the operational boundaries of PTFE. While its advantages are significant, it is not a universal solution.

Pressure and Temperature Ratings

Although PTFE has an excellent temperature range, it generally has lower pressure ratings than stainless steel or other metal alloy bellows. It is critical to ensure the system's operating pressure is well within the manufacturer's specifications for the specific bellow.

Susceptibility to Abrasion

The non-stick surface of PTFE is relatively soft. In applications involving highly abrasive slurries or solids, the liner can be susceptible to erosion over time, which may necessitate more frequent replacement compared to a hard-faced metal component.

Potential for Creep

Under high, constant mechanical loads (compressive or tensile), PTFE can be subject to "creep," or slow plastic deformation. Proper system design and ensuring the bellows are not over-extended or over-compressed is essential for long service life.

Making the Right Choice for Your System

Selecting the right expansion bellow requires aligning the component's strengths with your primary operational challenge.

- If your primary focus is handling highly corrosive chemicals: The near-total chemical inertness of PTFE offers unparalleled protection, directly preventing failures and costly leaks.

- If your primary focus is reducing system vibration and noise: The inherent flexibility of PTFE absorbs mechanical stress, protecting pumps, piping, and other critical assets from premature wear.

- If your primary focus is maintaining sanitary or high-purity conditions: The non-adhesive, hygienic properties of PTFE minimize contamination risks and simplify cleaning protocols, reducing operational labor.

Ultimately, choosing PTFE expansion bellows is an investment in the long-term stability and efficiency of your entire piping system.

Summary Table:

| Key Benefit | How It Reduces Maintenance Costs |

|---|---|

| Chemical Inertness | Prevents corrosion and degradation, eliminating leaks and failures. |

| Thermal Stability | Withstands temperature cycling, preventing stress fractures. |

| Vibration Damping | Protects connected equipment from premature wear. |

| Non-Adhesive Surface | Prevents buildup and clogging, reducing cleaning cycles. |

| Lightweight & Flexible | Simplifies installation and replacement, saving labor hours. |

Ready to slash your maintenance costs and boost system reliability?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE bellows are designed to withstand corrosive chemicals, extreme temperatures, and mechanical stress, delivering the longevity that directly translates to lower maintenance expenses and less downtime for your operations.

Whether you need a prototype or a high-volume order, we provide custom fabrication to meet your specific system requirements. Contact us today to discuss how our PTFE solutions can enhance your operational efficiency and reduce your total cost of ownership.

Get a Quote & Discuss Your Application

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What role does PTFE play in vibration dampening in piping systems? | Reduce Stress & Wear

- What is the temperature range for expanded PTFE? From -400°F to 500°F for Extreme Environments

- What are the thermal and electrical performance characteristics of Teflon PTFE? Master Its Properties for Demanding Applications

- What are the key design advantages of PTFE components? Achieve Superior Performance in Harsh Environments

- What are the key advantages of PTFE slide bearings in construction? Achieve Maintenance-Free Structural Movement

- What role does PTFE play in the printing and packaging industry? Enhancing Efficiency and Quality

- Why is tool selection important in the CNC machining of PTFE parts? Achieve Precision and Quality

- What are the cost and supply challenges associated with PTFE laminates? Navigating High Costs and Complex Supply Chains