At its core, the primary advantage of a PTFE slide bearing is its ability to create a near-frictionless, maintenance-free surface that reliably accommodates structural movement. These components are specified in major construction projects because they combine an exceptionally low coefficient of friction with extreme durability, chemical inertness, and high load-bearing capacity, ensuring the long-term integrity of the structure.

The crucial insight is that PTFE bearings are not just components; they are a 'fit-and-forget' engineering solution. Their value is measured over the entire lifecycle of a structure, where they eliminate the cost and complexity of ongoing maintenance while predictably managing forces like thermal expansion and seismic shifts.

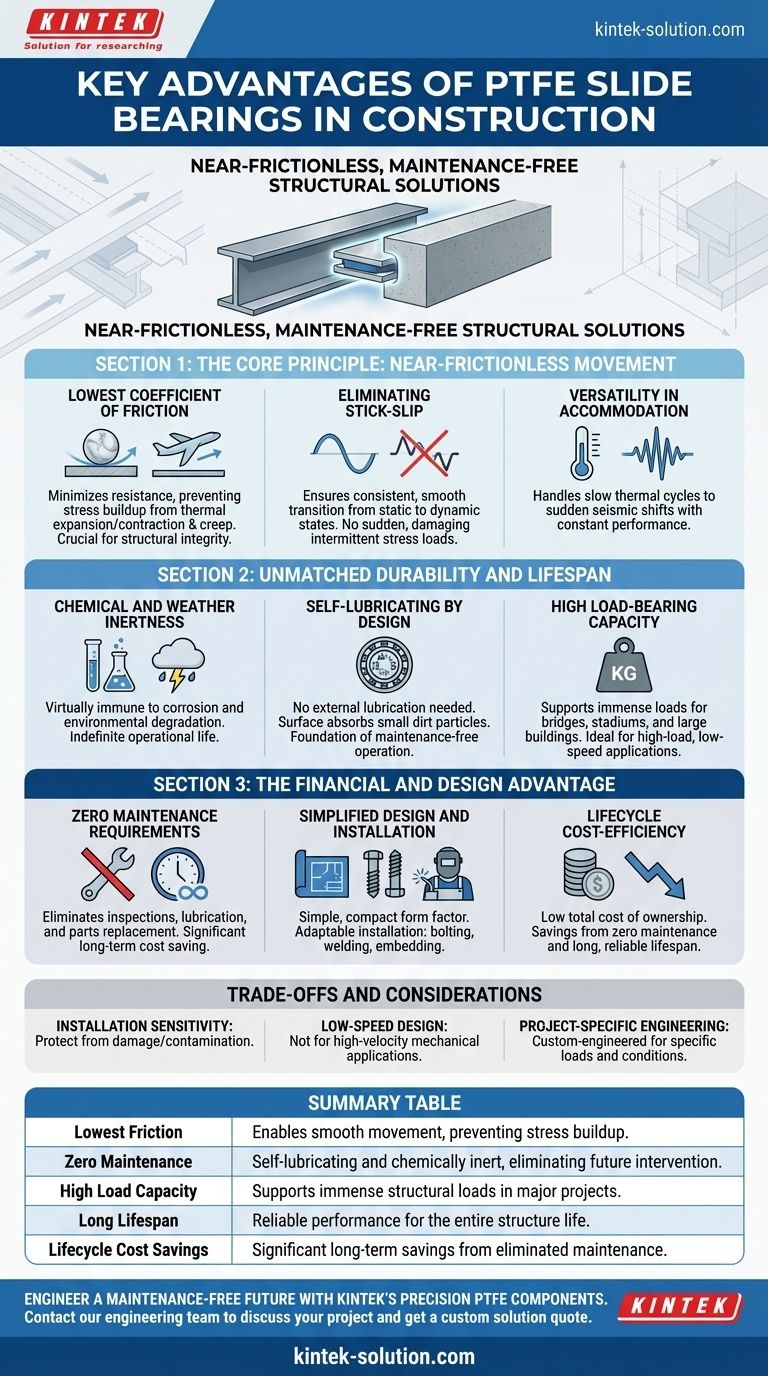

The Core Principle: Near-Frictionless Movement

Modern structures are not static; they must be designed to move. PTFE (Polytetrafluoroethylene) slide bearings are engineered to manage this movement with unparalleled efficiency and reliability.

Lowest Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any solid material known. This property allows massive structural elements to slide past each other with minimal resistance.

This smooth movement is critical for preventing the buildup of stress within the structure that would otherwise be caused by thermal expansion and contraction, creep, or post-tensioning.

Eliminating Stick-Slip

A key technical advantage is the absence of "stick-slip," a phenomenon where static friction builds up and releases suddenly, causing jarring movement.

PTFE provides a consistent, smooth transition from static to dynamic states, ensuring predictable behavior and protecting the structure from damaging, intermittent stress loads.

Versatility in Accommodation

These bearings are designed to handle a wide range of movements, from slow, cyclical thermal changes to the more sudden shifts associated with seismic activity. Their performance remains constant under these worst-case conditions.

Unmatched Durability and Lifespan

The material properties of PTFE make it exceptionally resilient, ensuring it performs its function for the intended lifespan of the structure without degradation.

Chemical and Weather Inertness

PTFE is chemically inert, meaning it is virtually immune to corrosion from chemicals, moisture, and other environmental agents. This guarantees an indefinite operational life without material breakdown.

Self-Lubricating by Design

The low-friction nature of PTFE is an inherent property of the material itself. It requires no external lubrication, which is the foundation of its maintenance-free operation.

Furthermore, its surface can absorb small dirt particles, preventing them from compromising the sliding action over time.

High Load-Bearing Capacity

Despite their simple appearance, PTFE slide bearings are engineered to support immense structural loads. They are specifically designed for high-load, low-speed applications common in bridges, stadiums, and large buildings.

The Financial and Design Advantage

The operational benefits of PTFE bearings translate directly into significant economic and design efficiencies throughout a project's lifecycle.

Zero Maintenance Requirements

The self-lubricating and inert nature of PTFE completely eliminates the need for maintenance. This is a massive long-term cost saving, removing the need for future inspections, lubrication, or parts replacement in often inaccessible locations.

Simplified Design and Installation

The simple, compact form factor of PTFE bearings simplifies both structural design and on-site installation. Common installation methods include bolting, welding, or embedding in mortar, making them adaptable to various construction workflows.

Lifecycle Cost-Efficiency

While a specialized component, the total cost of ownership is remarkably low. The savings from zero maintenance, simplified design, and a long, reliable lifespan make PTFE bearings a highly cost-effective solution for managing structural movement.

Understanding the Trade-offs and Considerations

While highly effective, it's important to understand the specific context in which PTFE bearings excel.

Sensitivity During Installation

The PTFE surface is the critical component. It must be protected from damage and contamination (like weld spatter or construction debris) during the installation process to ensure optimal long-term performance.

Designed for Low-Speed Movement

These bearings are engineered for the slow, high-load movements typical of civil structures. They are not intended for high-velocity mechanical applications.

Custom, Project-Specific Engineering

PTFE slide bearings are not off-the-shelf parts. They are engineered for the specific loads, movements, and environmental conditions of a particular project, placing a high degree of responsibility on correct initial design and specification.

Making the Right Choice for Your Structure

Selecting the right bearing system depends on prioritizing the long-term goals of the structure.

- If your primary focus is long-term reliability and zero maintenance: PTFE is the definitive choice for accommodating predictable structural movements without requiring any future intervention.

- If your primary focus is cost-efficiency across the project lifecycle: The complete elimination of maintenance costs makes PTFE an exceptionally economical solution for permanent structures.

- If your primary focus is design simplicity and predictable performance: The constant coefficient of friction and simple form factor simplify engineering calculations and reduce complexity in structural design.

Ultimately, choosing PTFE slide bearings is an investment in the certainty and long-term health of your structure.

Summary Table:

| Key Advantage | Description |

|---|---|

| Lowest Friction | Enables smooth movement, preventing stress buildup from thermal expansion or seismic shifts. |

| Zero Maintenance | Self-lubricating and chemically inert, eliminating the need for future inspections or lubrication. |

| High Load Capacity | Engineered to support immense structural loads in bridges, stadiums, and large buildings. |

| Long Lifespan | Chemically inert material ensures reliable performance for the entire life of the structure. |

| Lifecycle Cost Savings | Initial investment is offset by significant long-term savings from eliminated maintenance. |

Engineer a maintenance-free future for your structure with KINTEK's precision PTFE components.

Your construction projects demand reliability and long-term cost efficiency. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication expertise, from prototypes to high-volume orders, ensuring your PTFE slide bearings are engineered to the exact specifications your project requires.

Contact our engineering team today to discuss your project's specific needs and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials