To be direct, the primary cost and supply challenges associated with PTFE laminates are significantly higher material and manufacturing expenses, restrictive minimum order quantities (MOQs), and extended lead times compared to standard materials like FR-4. These issues are not arbitrary market factors but are direct consequences of PTFE's unique and demanding chemical properties, which complicate every step of the production process.

The exceptional high-frequency performance of PTFE comes at a steep price, not just in dollars but in supply chain rigidity. These challenges are rooted in the material's fundamental nature, which requires specialized, less-scalable manufacturing techniques that are fundamentally more complex and costly than those for conventional PCB materials.

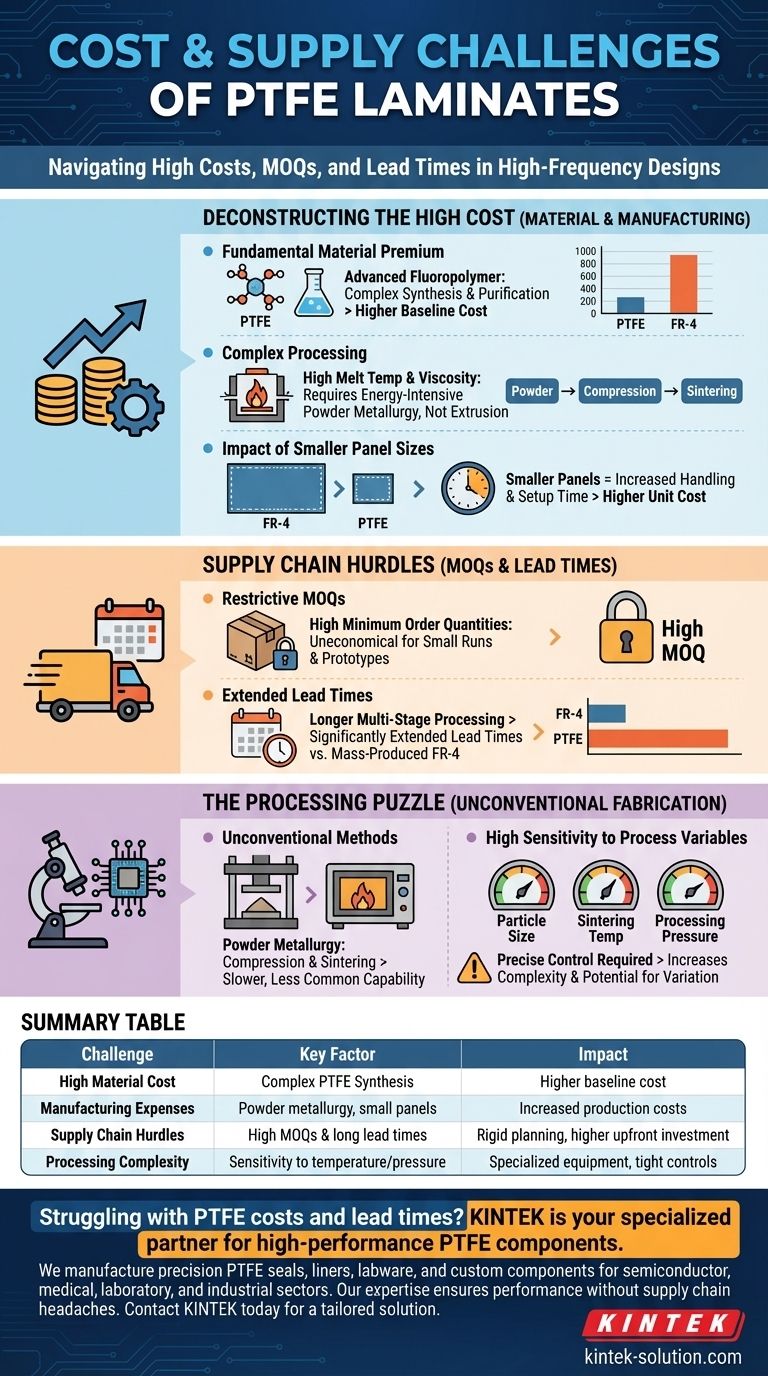

Deconstructing the High Cost of PTFE

The price premium for PTFE is not a simple markup; it's an accumulation of costs stemming from the raw material and the intricate processes required to turn it into a usable laminate for printed circuit boards (PCBs).

The Fundamental Material Premium

Polytetrafluoroethylene (PTFE) is an advanced fluoropolymer. Its synthesis and purification are inherently more complex and resource-intensive than producing the glass-reinforced epoxy that forms the basis of FR-4, establishing a higher baseline cost from the very start.

Complex Processing Drives Up Price

PTFE has an extremely high melting temperature and high-melt viscosity. This means it doesn't flow easily like common plastics, making conventional methods like injection molding or extrusion impractical. Instead, its processing more closely resembles powder metallurgy, a multi-step, energy-intensive technique.

The Impact of Smaller Panel Sizes

For manufacturing efficiency, larger laminate panels are always preferred. However, PTFE PCBs are often produced in smaller panel sizes, which increases handling and setup time per unit area. This inefficiency in fabrication directly translates to a higher final cost for the end user.

Navigating the Supply Chain Hurdles

Beyond direct costs, the realities of PTFE manufacturing create significant logistical challenges that impact project planning, prototyping, and production scale-up.

Minimum Order Quantities (MOQs)

The specialized equipment and setup required for PTFE laminate production are not economical for small runs. To ensure a viable production cycle, suppliers often impose high minimum order quantities (MOQs), passing these bulk purchasing requirements and costs on to their customers.

Extended Lead Times

The multi-stage, sensitive nature of PTFE processing simply takes longer than the highly optimized, mass-production workflows for FR-4. This results in significantly longer lead times, which must be factored into any project timeline from the very beginning.

The Processing Puzzle: Why PTFE is Different

Understanding why PTFE is difficult to work with is key to appreciating its associated costs and supply constraints. The material's properties defy standard manufacturing paradigms.

Unconventional Fabrication Methods

The need to process PTFE using techniques similar to powder metallurgy—involving compression and sintering (baking) of powder—is the core of the challenge. This is a slower, more precise, and less common capability than the high-volume lamination process used for other materials.

High Sensitivity to Process Variables

The final electrical and mechanical properties of a PTFE laminate are heavily dependent on precise control over particle size, sintering temperature, and processing pressure. This lack of tolerance requires extremely tight process controls, increasing complexity, cost, and the potential for batch-to-batch variation if not managed perfectly.

Making the Right Choice for Your Application

Ultimately, the decision to use PTFE must be a deliberate one, weighing its unparalleled electrical performance against its tangible business and logistical impacts.

- If your primary focus is absolute high-frequency performance: You must accept PTFE's challenges and proactively budget for higher costs and build extended timelines into your project plan to accommodate MOQs and lead times.

- If your primary focus is cost-sensitive mass production: PTFE is almost certainly not a viable option, and efforts should be directed toward alternative high-performance materials or advanced design techniques using more common substrates.

- If your primary focus is rapid prototyping or small batches: Be prepared for significant challenges in sourcing a supplier, and expect disproportionately high costs due to the minimum order quantities imposed by the supply chain.

Understanding these inherent manufacturing constraints empowers you to strategically decide when PTFE's performance benefits justify the significant investment of time and resources.

Summary Table:

| Challenge | Key Factor | Impact |

|---|---|---|

| High Material Cost | Complex PTFE synthesis and processing | Higher baseline cost than FR-4 |

| Manufacturing Expenses | Powder metallurgy techniques, smaller panel sizes | Increased production costs and inefficiencies |

| Supply Chain Hurdles | High MOQs and extended lead times | Rigid planning and higher upfront investment |

| Processing Complexity | Sensitivity to temperature and pressure | Requires specialized equipment and tight controls |

Struggling with PTFE laminate costs and lead times? KINTEK is your specialized partner for high-performance PTFE components.

We manufacture precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the performance you need without the supply chain headaches.

Let us help you navigate the complexities of PTFE. Contact KINTEK today to discuss your project requirements and receive a tailored solution that meets your budget and timeline.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments