In essence, the key design advantages of Polytetrafluoroethylene (PTFE) components stem from a unique combination of properties. These include an extremely low coefficient of friction, exceptional chemical inertness, high resistance to temperature extremes, and excellent electrical insulation. This powerful mix makes PTFE a premier problem-solving material for engineers designing components for harsh or highly specialized environments.

The true advantage of PTFE isn't a single feature, but its molecular stability. The strong carbon-fluorine bonds create a non-reactive, low-friction, and resilient material, making it an elite choice for applications where other materials would quickly fail.

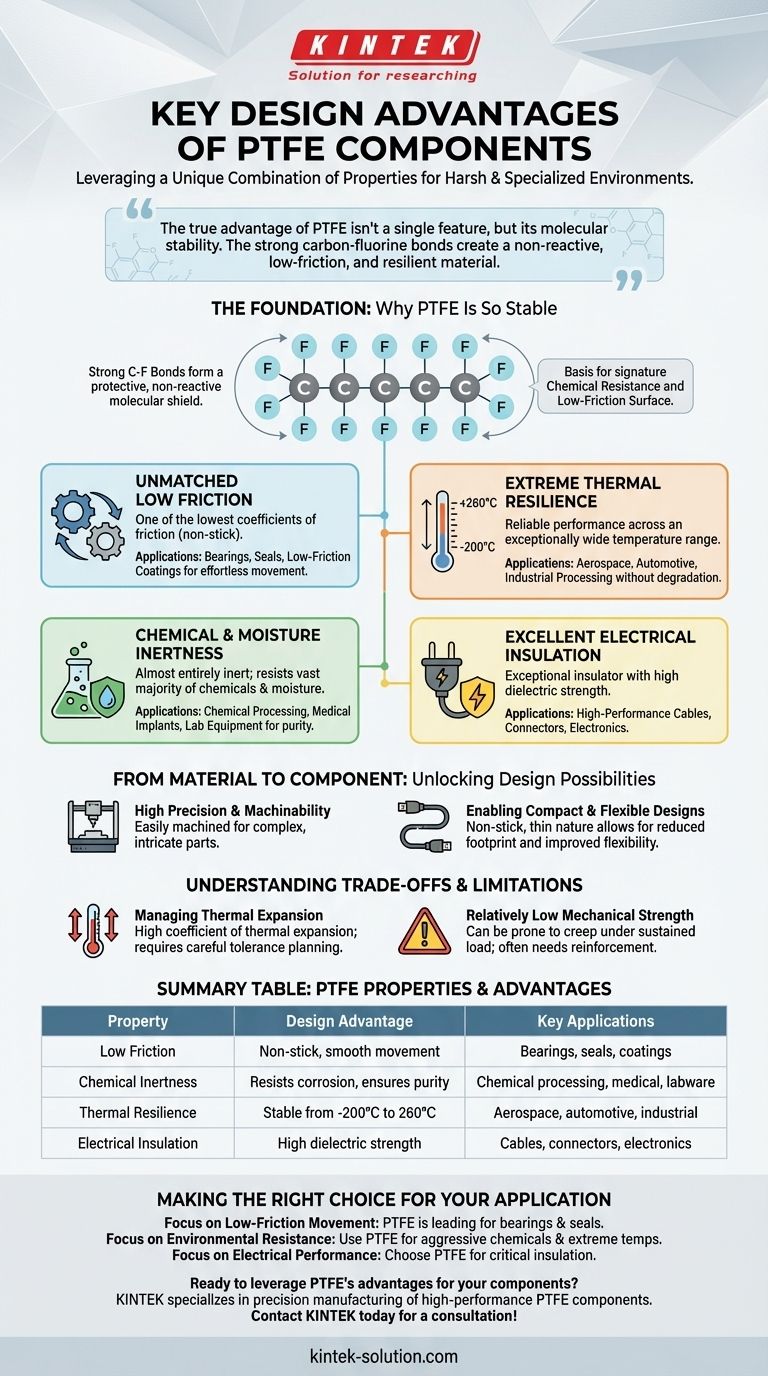

The Foundation: Why PTFE Is So Stable

PTFE’s remarkable properties are not accidental; they are a direct result of its unique molecular structure. Understanding this foundation is key to leveraging its design advantages.

A Unique Molecular Shield

The building blocks of PTFE are carbon and fluorine. Strong carbon-fluorine bonds form the backbone of the polymer, with the fluorine atoms creating a tight, protective sheath around the carbon chain.

This molecular shield is extremely non-reactive. It is the fundamental reason for PTFE's signature chemical resistance and low-friction surface.

Core Properties and Their Design Implications

Each of PTFE's primary characteristics translates directly into a tangible benefit for component design, from industrial seals to medical devices.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a signature "non-stick" quality.

This makes it an ideal material for bearings, seals, and low-friction coatings where smooth, effortless movement is critical to a component's function and longevity.

Extreme Thermal Resilience

PTFE components perform reliably across an exceptionally wide temperature range, from cryogenic lows (-200°C) to high heat (up to 260°C).

This thermal stability allows engineers to design parts for demanding aerospace, automotive, and industrial processing applications without fear of material degradation.

Chemical and Moisture Inertness

Because of its stable molecular structure, PTFE is almost entirely inert and does not react with the vast majority of chemicals. It also has excellent moisture resistance.

This property is crucial for components used in chemical processing, medical implants, and laboratory equipment, ensuring purity and preventing corrosion or material breakdown.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with high dielectric strength.

This makes it a go-to material for high-performance cables, connectors, and insulating components in the electronics and telecommunications industries.

From Material to Manufactured Component

Beyond its raw properties, PTFE's compatibility with modern manufacturing techniques unlocks further design possibilities.

High Precision and Machinability

Despite its unique properties, PTFE is a versatile material that is relatively easy to machine using CNC methods.

This allows for the creation of complex and intricate parts with high-quality assurance and minimal material waste, which is essential for precision engineering.

Enabling Compact and Flexible Designs

The non-stick, thin nature of PTFE is perfect for creating compact components where layers must slide past each other with minimal friction.

This is a key advantage in applications like advanced cable design, where PTFE layers reduce the cable's overall footprint while improving its flexibility.

Understanding the Trade-offs and Limitations

To be a trusted advisor, it is critical to acknowledge that no material is perfect. While powerful, PTFE has specific limitations that every designer must consider.

Managing Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes.

Designers must account for this behavior in their tolerances to avoid component failure, especially when PTFE is integrated with dimensionally stable materials like steel.

Relatively Low Mechanical Strength

While it possesses good tensile strength for a fluoropolymer, PTFE is a relatively soft material that can be prone to "creep" or deformation under sustained load.

It is not ideal for high-load structural applications unless reinforced or supported by other components, such as in a metal-backed sliding bearing.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the specific problem you need to solve.

- If your primary focus is low-friction movement: PTFE is an industry-leading choice for bearings, seals, and non-stick surfaces where efficiency and longevity are key.

- If your primary focus is environmental resistance: Use PTFE for components that will be exposed to aggressive chemicals, extreme temperatures, or moisture.

- If your primary focus is electrical performance: Choose PTFE for critical insulating components or high-frequency applications where signal integrity is paramount.

By understanding these core advantages and their associated trade-offs, you can leverage PTFE not just as a material, but as a strategic solution to complex engineering problems.

Summary Table:

| Property | Design Advantage | Key Applications |

|---|---|---|

| Low Friction | Non-stick, smooth movement | Bearings, seals, coatings |

| Chemical Inertness | Resists corrosion, ensures purity | Chemical processing, medical, labware |

| Thermal Resilience | Stable from -200°C to 260°C | Aerospace, automotive, industrial |

| Electrical Insulation | High dielectric strength | Cables, connectors, electronics |

Ready to leverage PTFE's advantages for your components?

KINTEK specializes in the precision manufacturing of high-performance PTFE components like seals, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume production.

Our expertise ensures your parts are designed to maximize PTFE's benefits while accounting for its unique characteristics. Let's solve your most challenging design problems together.

Contact KINTEK today for a consultation on your PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the characteristics and applications of PTFE beading? Solve Sealing and Friction Problems

- How are PTFE bellow seals affected by environmental factors? Discover Their Exceptional Resilience

- What are the uses of Polytetrafluoroethylene (PTFE) with a Proprietary Fill? Enhance Performance for Demanding Applications

- How are PTFE packings applied in the chemical industry? Ensure Leak-Free Sealing for Hazardous Fluids

- What are the main applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & High-Temp Environments

- Why are PTFE ball valves preferred for cryogenic applications? Unlock Reliable Sealing at Ultra-Low Temperatures

- What are the common plumbing applications of PTFE? Ensure Leak-Proof, Durable Seals

- What advantages do custom PTFE parts offer for industrial efficiency? Boost Uptime & Cut Costs