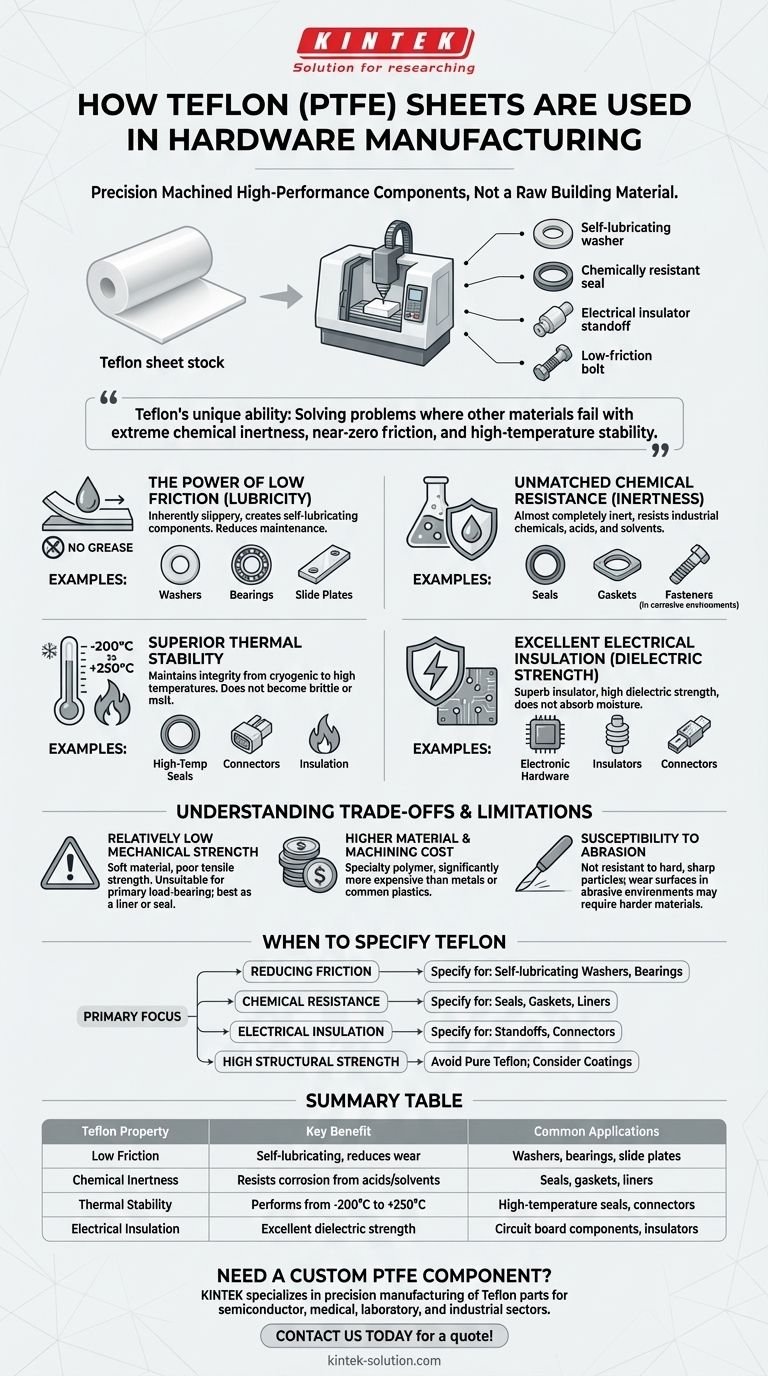

In hardware manufacturing, Teflon (PTFE) sheets are not used as a raw building material like steel but are precisely machined to create high-performance components. These include parts like self-lubricating washers, chemically resistant seals, electrical insulators, and low-friction bolts or pins. The sheet form serves as the stock material from which these specialized parts are cut, stamped, or milled for use in demanding industrial, electronic, and aerospace applications.

The core reason Teflon is used in hardware is not for strength, but for its unique ability to solve problems where other materials fail. Its value lies in an unparalleled combination of extreme chemical inertness, near-zero friction, and high-temperature stability, making it the material of choice for the most challenging environments.

Why Teflon is a Go-To Material for Critical Hardware

While many materials are "durable," Teflon's value comes from a specific set of engineered properties. Manufacturing professionals turn to it when a component must perform reliably under conditions that would cause conventional metals or plastics to seize, corrode, or melt.

The Power of Low Friction (Lubricity)

Teflon has one of the lowest coefficients of friction of any known solid. This means it is inherently slippery, a property often referred to as lubricity.

In manufacturing, this is used to create self-lubricating components. Washers, bearings, or slide plates made from Teflon require no external grease or oil, reducing maintenance and eliminating a point of failure in moving assemblies.

Unmatched Chemical Resistance (Inertness)

Teflon is almost completely chemically inert, meaning it does not react with the vast majority of industrial chemicals, acids, and solvents.

This makes it the ideal material for creating seals, gaskets, and even fasteners (nuts and bolts) used in chemical processing plants, fuel systems, or laboratory equipment where corrosion would destroy metal or other plastics.

Superior Thermal Stability

Teflon maintains its structural integrity and key properties across an exceptionally wide range of temperatures, from cryogenic lows to highs exceeding 250°C (482°F).

This thermal stability ensures that components like engine seals, high-temperature connectors, and insulation maintain their performance without becoming brittle or melting in extreme operational environments.

Excellent Electrical Insulation (Dielectric Strength)

Beyond its mechanical properties, Teflon is a superb electrical insulator with very high dielectric strength. It resists the flow of electricity and does not absorb moisture, which can degrade insulating performance.

This makes it critical for manufacturing electronic hardware, such as high-frequency connectors, circuit board components, and insulators where signal integrity and safety are paramount.

Understanding the Trade-offs and Limitations

While powerful, Teflon is not a universal solution. Its unique properties come with specific trade-offs that are critical to understand before specifying it for a component.

Relatively Low Mechanical Strength

Teflon is a soft material. It has poor tensile strength and is susceptible to "creep," meaning it can slowly deform over time when under a constant load.

It is therefore unsuitable for high-load structural applications where it would be the primary load-bearing element. It functions best as a liner, seal, or washer within a stronger metal assembly.

Higher Material and Machining Cost

Teflon is a specialty polymer and is significantly more expensive than common materials like nylon, steel, or aluminum.

Its use is typically justified only when its unique performance characteristics are a strict requirement for the application's success and longevity.

Susceptibility to Abrasion

While Teflon has low friction, it is not highly resistant to abrasion from hard, sharp particles. In environments with abrasive contaminants, a harder material might be a better choice for wear surfaces.

When to Specify Teflon for Your Hardware

Choosing Teflon is about solving a specific engineering challenge, not just selecting a durable material. Use its properties as a guide for your decision.

- If your primary focus is reducing friction and wear: Use Teflon for self-lubricating components like washers, slide bearings, and wear pads in moving systems.

- If your primary focus is chemical or environmental resistance: Specify Teflon for seals, gaskets, and liners in corrosive environments or systems handling aggressive fluids.

- If your primary focus is electrical insulation: Choose Teflon for standoffs, connectors, and insulators where high dielectric strength is critical, especially at high frequencies or temperatures.

- If your primary focus is high structural strength: Avoid using pure Teflon for load-bearing parts; instead, consider it for coatings or as a specialty component within a stronger assembly.

By understanding its unique strengths and limitations, you can leverage Teflon not just as a material, but as a strategic solution to complex engineering problems.

Summary Table:

| Teflon Property | Key Benefit in Hardware | Common Applications |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Washers, bearings, slide plates |

| Chemical Inertness | Resists corrosion from acids/solvents | Seals, gaskets, liners |

| Thermal Stability | Performs from -200°C to +250°C | High-temperature seals, connectors |

| Electrical Insulation | Excellent dielectric strength | Circuit board components, insulators |

Need a custom PTFE component that solves your toughest engineering challenges?

KINTEK specializes in precision manufacturing of Teflon parts—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors. We deliver components that offer unmatched chemical resistance, low friction, and thermal stability.

Contact us today to discuss your specific requirements and get a quote for your custom PTFE solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Are metric sizes available for PTFE balls? Ensuring Precision with the Right Tolerance

- What are some alternatives to Teflon for machining? Optimize Your Material Selection for Specialized Applications

- What types of chemicals can ePTFE gaskets withstand? Seal Aggressive Media with Near-Universal Resistance

- What factors influence the design variations of PTFE valves? Select the Perfect Valve for Your Application

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- What are the advantages of PTFE with a Proven Inorganic Filler? Maximize Metal Component Lifespan

- What are the installation and maintenance guidelines for Teflon bearings? Maximize Lifespan and Performance

- What are the additional characteristics of PTFE rods? Unlock Superior Performance in Harsh Environments