The primary advantages of Polytetrafluoroethylene (PTFE) with a Proven Inorganic Filler are its self-lubricating nature and, most critically, its exceptionally low wear on mating metal components. This unique blend offers excellent friction resistance and wear properties across a very wide temperature range, making it a highly reliable material for sensitive applications.

The core challenge in selecting a filled PTFE is balancing the lifespan of the PTFE component against the lifespan of the surface it contacts. This specific material's key advantage is that it prioritizes the preservation of critical metal parts, making it the superior choice when the integrity of a shaft, bore, or other dynamic surface is paramount.

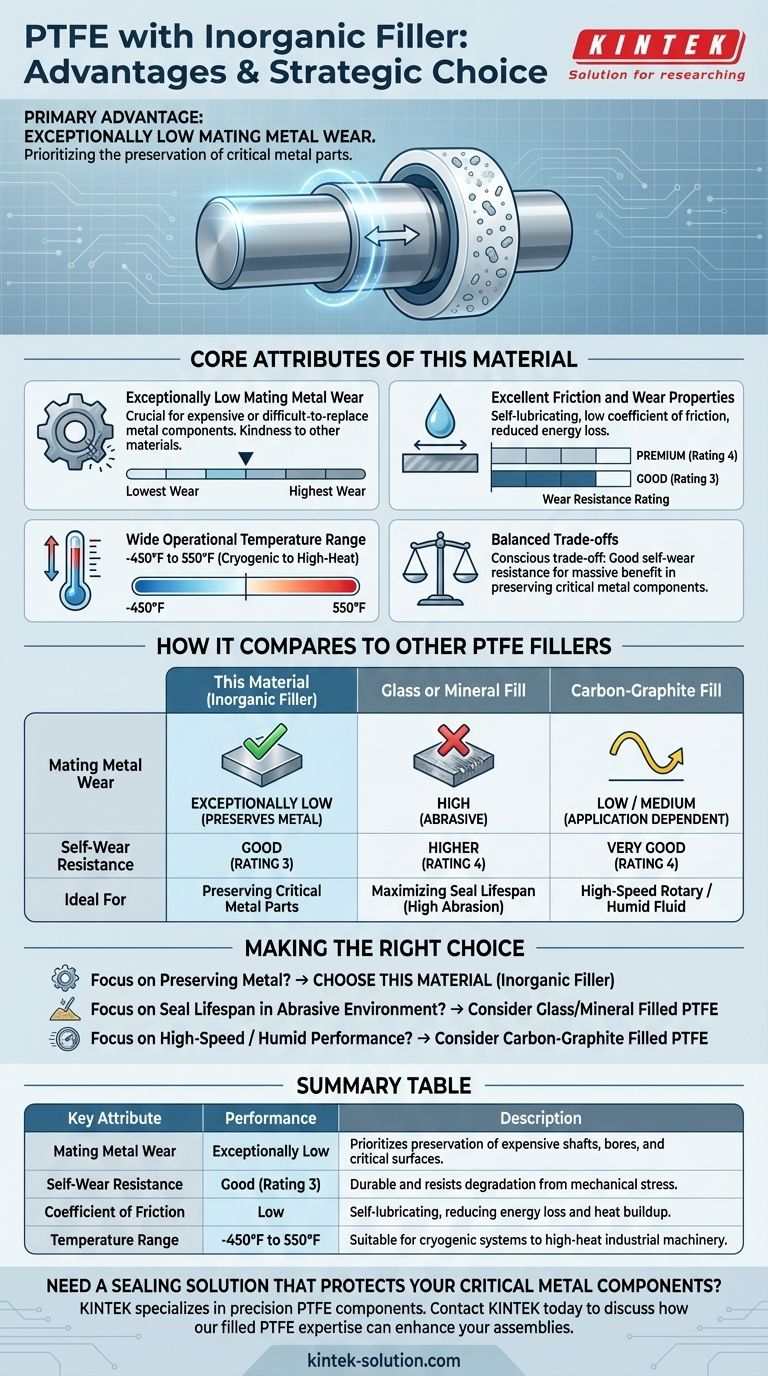

Core Attributes of This Material

This specific formulation of filled PTFE is engineered for a unique balance of properties. Its defining characteristic is how it interacts with other components in a system.

Exceptionally Low Mating Metal Wear

The standout feature is its kindness to other materials. Mating metal wear refers to the abrasion or damage that a seal or bearing causes to the metal surface (like a shaft) it moves against.

This material has one of the lowest metal-mating wear characteristics among all filled PTFE options. This is crucial when the metal component is expensive or difficult to replace.

Excellent Friction and Wear Properties

Like most PTFE variants, this material is inherently self-lubricating, providing a low coefficient of friction that reduces energy loss and heat buildup.

It has a good wear resistance rating of 3 (on the provided scale). While not the absolute highest, this rating signifies a durable material that resists degradation from mechanical stress.

Wide Operational Temperature Range

This blend operates effectively in extreme temperatures, from -450°F to 550°F. This thermal stability makes it suitable for applications ranging from cryogenic systems to high-heat industrial machinery.

How It Compares to Other PTFE Fillers

To understand its value, it is essential to compare this material to other common PTFE blends. The choice of filler dramatically changes the material's performance profile.

vs. Glass or Mineral Fill

PTFE with glass or mineral fillers offers higher intrinsic wear resistance (rated 4). However, this hardness comes at a cost.

Both of these fillers are highly abrasive and cause high mating metal wear. They will wear down the shaft or bore they are in contact with much more quickly.

vs. Carbon-Graphite Fill

Carbon-graphite fillers also provide low mating metal wear, making them a close alternative.

The distinction often lies in the specific application. Carbon-graphite blends are frequently optimized for very good wear resistance in high-speed rotary or fluid applications, sometimes achieving a wear rating of 4, but with a corresponding "medium" rating for mating metal wear.

Understanding the Trade-offs

No material is perfect for every scenario. Being objective about a material's limitations is key to successful engineering.

Moderate Self-Wear Resistance

The material's wear resistance rating of 3 is good, but it is not the highest available. Formulations with glass, mineral, or premium carbon fillers achieve a rating of 4.

This means you are consciously trading a small amount of the PTFE component's own lifespan to gain a massive benefit in preserving the more critical metal components of the assembly.

Not a Universal Solution

While its balanced profile makes it widely applicable, highly specialized systems may demand a different filler.

For example, an application with extreme contact pressure might require the superior compressive strength of a glass-filled PTFE, accepting the associated shaft wear as a necessary compromise.

Making the Right Choice for Your Application

Your final decision should be guided by the most critical priority for your system's longevity and performance.

- If your primary focus is preserving an expensive or hard-to-replace metal component: This material is the optimal choice due to its exceptionally low mating metal wear.

- If your primary focus is maximizing the seal's own lifespan in a highly abrasive environment: A glass or mineral-filled PTFE might be more suitable, provided you can tolerate accelerated wear on the mating surface.

- If your primary focus is performance in high-speed rotary or humid fluid applications: A carbon-graphite filled PTFE may offer a better combination of low friction and high wear resistance for those specific conditions.

Ultimately, selecting the right filled PTFE is about strategically balancing the wear characteristics of the entire dynamic system.

Summary Table:

| Key Attribute | Performance | Description |

|---|---|---|

| Mating Metal Wear | Exceptionally Low | Prioritizes preservation of expensive shafts, bores, and other critical metal surfaces. |

| Self-Wear Resistance | Good (Rating 3) | Durable and resists degradation from mechanical stress. |

| Coefficient of Friction | Low | Self-lubricating, reducing energy loss and heat buildup. |

| Temperature Range | -450°F to 550°F | Suitable for cryogenic systems to high-heat industrial machinery. |

Need a Sealing Solution that Protects Your Critical Metal Components?

If your application's success depends on preserving expensive or hard-to-replace metal parts, this specific PTFE blend is the ideal choice. Its exceptionally low mating metal wear ensures the longevity of your shafts, bores, and other dynamic surfaces.

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring the perfect material solution for your unique requirements.

Contact KINTEK today to discuss how our filled PTFE expertise can enhance the reliability and lifespan of your assemblies.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability