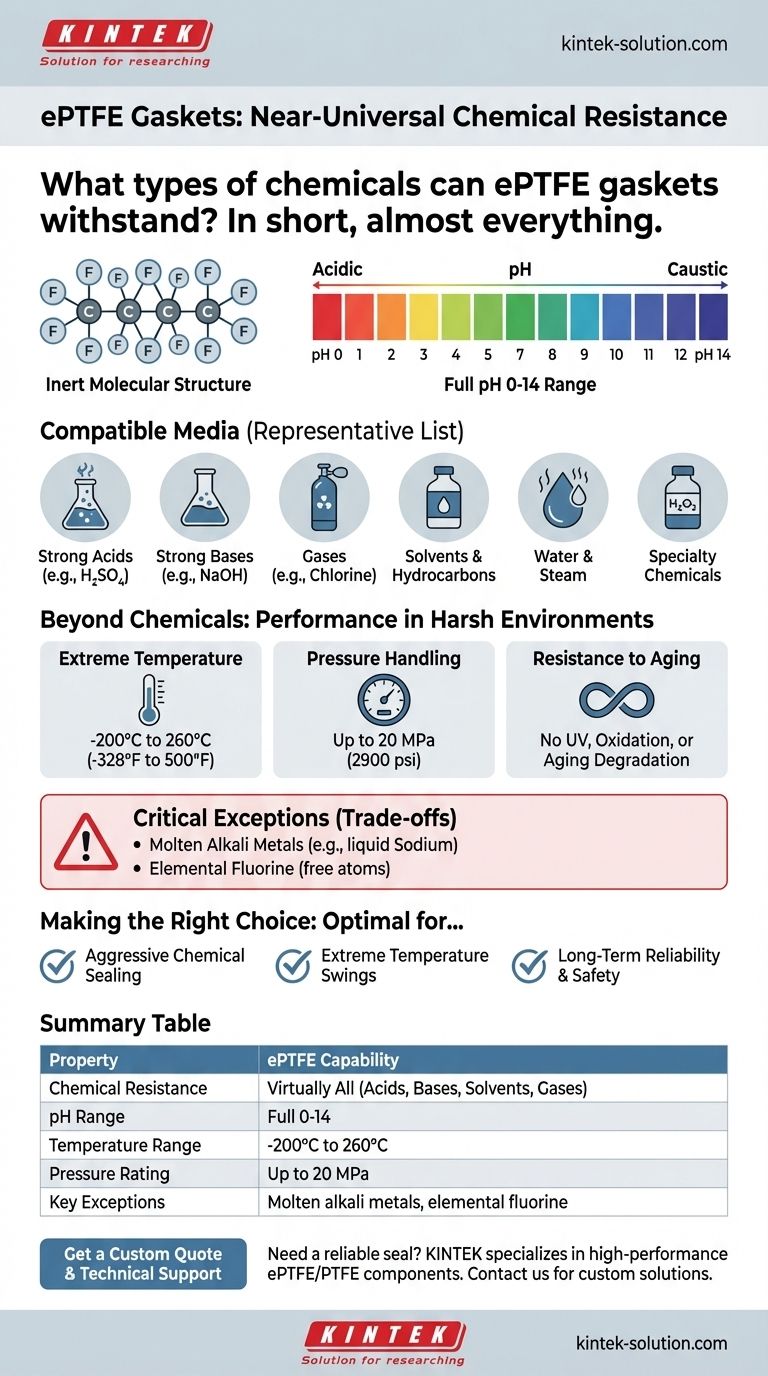

In short, almost everything. Expanded Polytetrafluoroethylene (ePTFE) gaskets offer near-universal chemical resistance. They are engineered to reliably seal a vast range of aggressive media, including strong acids, strong bases, solvents, hydrocarbons, and reactive gases like chlorine, across the entire 0-14 pH spectrum.

The core takeaway is that ePTFE's chemical inertness is its defining feature. Its unique molecular structure makes it impervious to virtually all chemicals found in industrial processes, with only two rare and specific exceptions: molten alkali metals and elemental fluorine.

Understanding ePTFE's Chemical Inertness

The remarkable resistance of ePTFE is not an accident; it is a direct result of the underlying chemistry of its base material, Polytetrafluoroethylene (PTFE).

The Foundation: A Stable Molecular Structure

The source of ePTFE's resilience lies in the powerful bonds between carbon and fluorine atoms in the PTFE molecule. These bonds are exceptionally strong and stable, creating a protective "shield" of fluorine atoms that prevents other chemicals from reacting with the carbon backbone.

This inherent stability means the gasket material does not swell, weaken, or degrade when exposed to corrosive fluids, ensuring a consistent and reliable seal.

A Comprehensive pH Range (0-14)

Practically speaking, ePTFE is suitable for service across the entire pH scale. This makes it one of the few gasket materials that can be standardized across a plant for both highly acidic (pH 0) and highly caustic (pH 14) applications.

This versatility simplifies inventory and eliminates the risk of using the wrong gasket material for a specific chemical service.

Representative Compatible Media

While the list is nearly endless, ePTFE gaskets are proven to handle some of the most challenging substances used in processing, including:

- Strong acids (e.g., sulfuric, nitric, hydrochloric)

- Strong bases (e.g., sodium hydroxide)

- Gases (e.g., chlorine)

- Solvents and hydrocarbons

- Water and steam

- Specialty chemicals like hydrogen peroxide and aluminum fluoride

Beyond Chemicals: Performance in Harsh Environments

An effective seal depends on more than just chemical compatibility. The physical properties of ePTFE allow it to maintain its integrity under a wide range of operational stressors.

Extreme Temperature Tolerance

ePTFE gaskets perform reliably in both cryogenic and high-temperature services. They maintain their properties in a very wide operational window, typically from -200°C (-328°F) up to 260°C (500°F).

Pressure Handling Capabilities

These gaskets are not just for corrosive fluids but also for pressurized systems. They are commonly rated to withstand significant internal pressures, often up to 20 MPa (approximately 2900 psi), ensuring a tight seal in demanding applications.

Resistance to Aging and Degradation

Unlike many elastomers and other sealing materials, PTFE is completely resistant to degradation from UV light, oxidation, and general aging. An ePTFE gasket will not become brittle or lose its sealing capability over time, ensuring permanent durability.

Understanding the Trade-offs: The Critical Exceptions

No material is perfect. To use ePTFE safely and effectively, you must be aware of its two specific chemical incompatibilities. These situations are rare in most industries but are critical to acknowledge.

Molten Alkali Metals

Materials like liquid sodium or potassium are highly reactive and are among the few substances that can chemically attack the PTFE structure. These are typically found in specialized nuclear or metallurgical processes.

Elemental Fluorine

While ePTFE is highly resistant to fluoride compounds (like aluminum fluoride), it can be attacked by free fluorine atoms, such as those found in liquid or gaseous elemental fluorine. This is because the material itself is a fluoropolymer, and this hyper-aggressive form of fluorine can disrupt its molecular bonds.

Making the Right Choice for Your Application

Selecting the correct gasket is a critical decision for process safety and efficiency. Based on its properties, ePTFE is the optimal choice for several distinct goals.

- If your primary focus is sealing aggressive chemicals: ePTFE is an ideal default choice due to its near-universal resistance across the full pH range, simplifying material selection and reducing risk.

- If your primary focus is processes with extreme temperature swings: Its exceptionally wide operational temperature range makes it one of the few materials suitable for both cryogenic and high-heat services.

- If your primary focus is long-term reliability and safety: ePTFE's immunity to chemical attack and environmental aging ensures a durable, long-lasting seal that minimizes the potential for leaks and fugitive emissions.

By understanding both its profound strengths and its specific limitations, you can confidently specify ePTFE for your most demanding sealing applications.

Summary Table:

| Property | ePTFE Gasket Capability |

|---|---|

| Chemical Resistance | Virtually all chemicals (acids, bases, solvents, gases) |

| pH Range | Full 0-14 spectrum |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| Pressure Rating | Up to 20 MPa (2900 psi) |

| Key Exceptions | Molten alkali metals, elemental fluorine |

Need a reliable seal for aggressive chemicals, extreme temperatures, or high-pressure systems?

KINTEK specializes in manufacturing high-performance ePTFE and PTFE components, including custom gaskets, seals, liners, and labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a sealing solution that guarantees safety, durability, and long-term reliability in the most demanding environments.

Contact us today to discuss your specific application requirements and let our experts provide a solution tailored for the semiconductor, medical, laboratory, and industrial sectors.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What new technologies are being applied to PTFE O-ring seals? Enhance Performance with Nanomaterials & 3D Printing

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor

- What standards and compliance measures are followed in manufacturing Teflon parts? Ensuring Quality from ISO to Final Inspection

- Which substances is PTFE not chemically resistive to? Avoid These Extreme Conditions

- What makes PTFE lined valves suitable for handling aggressive media? Superior Chemical Resistance for Harsh Fluids

- How should thin-wall PTFE components be clamped during machining? Prevent Deformation with the Right Fixtures

- What are the common applications of expanded PTFE? Unlock High-Performance Sealing, Filtration & Medical Solutions

- What design parameter must be considered when applying wide contact to spring-activated PTFE lip seals? Prevent Bell Mouthing to Avoid Catastrophic Leakage