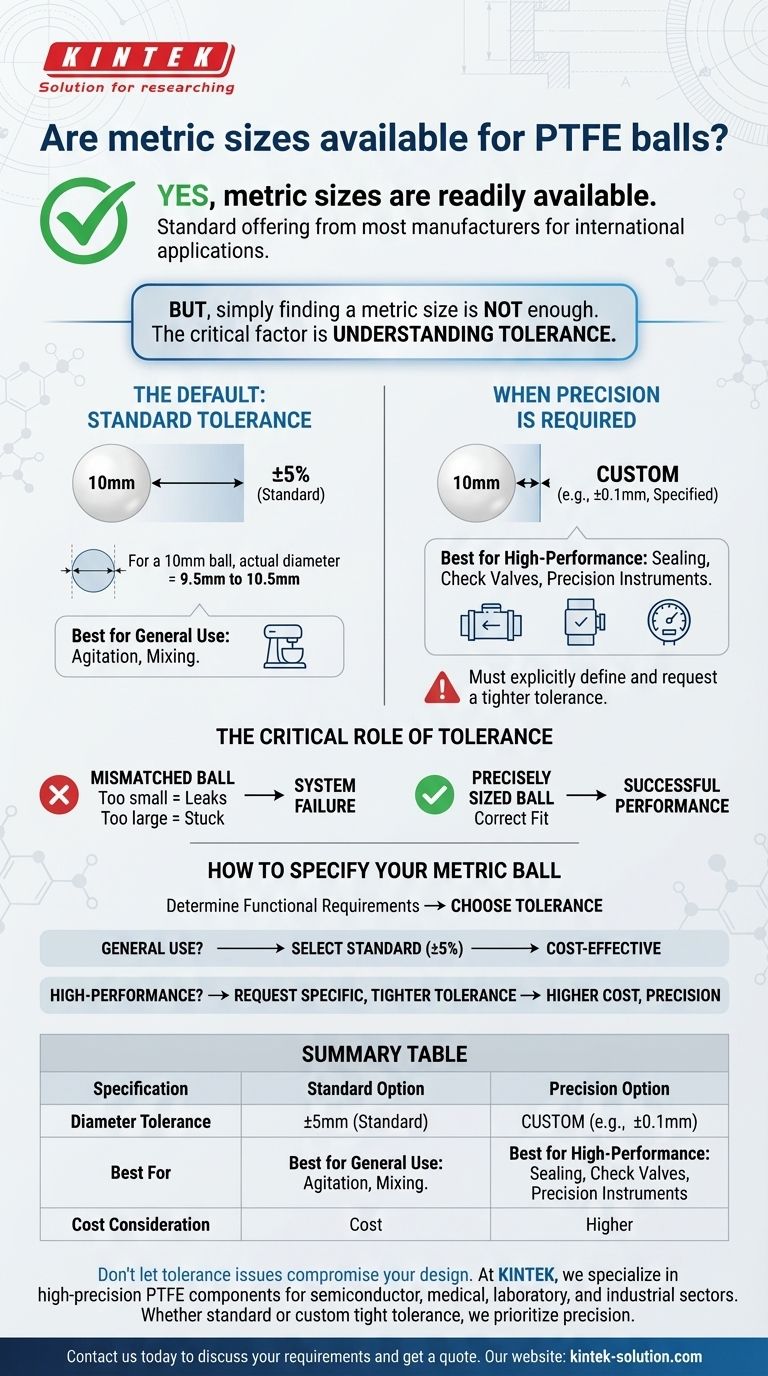

Yes, metric sizes are readily available for PTFE balls. They are a standard offering from most manufacturers, designed to meet the specifications of a wide range of international applications, from laboratory equipment to industrial valves. However, simply finding a metric size is not enough; the critical factor for proper function is understanding the manufacturing tolerance associated with that size.

While metric PTFE balls are widely available, the key to successful implementation lies in understanding their standard diameter tolerance. For any application requiring a precise fit, you must move beyond the default and explicitly specify a tighter, non-standard tolerance with your supplier.

Understanding PTFE Ball Specifications

Sourcing the correct component requires looking past the basic diameter. The material properties of PTFE (Polytetrafluoroethylene) lead to specific manufacturing considerations that directly impact how the ball will perform in your application.

Metric Availability Is the Norm

You will find PTFE balls offered in a comprehensive range of standard metric diameters. This ensures compatibility with a vast array of components and systems designed using the metric system.

Sourcing a metric-sized ball is typically a straightforward process. The challenge arises not from availability, but from ensuring the physical part matches your design's required precision.

The Default: Standard Diameter Tolerance

By default, PTFE balls are often manufactured to a standard diameter tolerance of ±5%. This is a crucial detail that is often overlooked.

For a 10mm ball, this tolerance means the actual diameter could be anywhere from 9.5mm to 10.5mm. For applications like simple agitation or mixing, this wide range is perfectly acceptable.

When Precision Is Required

For applications demanding a more exact fit, such as in check valves or precision bearings, a ±5% tolerance is usually inadequate.

In these cases, precision diameter tolerances are available. These are not standard and must be specified per item when you order. You must communicate your exact requirements, such as ±0.1mm, to the manufacturer.

The Critical Role of Tolerance

Ignoring tolerance is one ofthe most common pitfalls when specifying components made from "soft" materials like PTFE. The difference between a standard and a precision ball determines the success or failure of the final assembly.

The Risk of a Mismatched Ball

An incorrectly sized ball can cause immediate functional problems. A ball that is too small in a check valve will fail to create a proper seal, leading to leaks. A ball that is too large may get stuck or prevent proper flow entirely.

This is why understanding your application's tolerance needs is non-negotiable.

Balancing Cost and Performance

Achieving a tighter, more precise tolerance requires more complex manufacturing processes and stricter quality control, which increases the cost per unit.

The central trade-off is between cost and precision. Specifying a tolerance that is unnecessarily tight for your application leads to needless expense. Conversely, opting for a cheaper, standard-tolerance ball in a precision application will lead to system failure.

How to Specify Your Metric Ball

Use your application's functional requirements to determine the necessary level of precision.

- If your primary focus is general use or non-critical applications: Standard tolerance (±5%) metric balls are a cost-effective and suitable choice.

- If your primary focus is high-performance sealing, check valves, or precision instruments: You must explicitly define and request a specific, tighter diameter tolerance from your supplier.

Properly specifying both the size and the tolerance ensures your component performs exactly as your design intends.

Summary Table:

| Specification | Standard Option | Precision Option |

|---|---|---|

| Diameter Tolerance | ±5% (e.g., 9.5mm - 10.5mm for a 10mm ball) | Custom (e.g., ±0.1mm), specified per order |

| Best For | General use, agitation, mixing | High-performance sealing, check valves, precision instruments |

| Cost Consideration | Cost-effective | Higher cost due to complex manufacturing |

Don't let tolerance issues compromise your design.

At KINTEK, we specialize in manufacturing high-precision PTFE components, including balls, seals, liners, and labware. We understand that a precise fit is paramount for success in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a standard metric ball or a custom-fabricated part with a specific, tight tolerance—from prototypes to high-volume orders—we prioritize precision production to ensure your components perform flawlessly.

Contact us today to discuss your specific requirements and get a quote. Reach out via our contact form

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What considerations are important for PTFE CNC machining? Master Precision Machining for High-Performance Components

- What industries commonly use PTFE-lined plug valves and why? Ensure Safety and Purity in Demanding Applications

- Why is CNC machining suitable for custom Teflon parts? Achieve Precision for Demanding Applications

- What are the primary functions of PTFE expansion bellows? Absorb Movement, Dampen Vibration, and Protect Pipes

- What is the operating temperature range for Teflon encapsulated O-rings? -60°C to +205°C Guide

- How does PTFE perform when bearing surfaces become contaminated? Maintain Reliable Performance in Unclean Environments

- Why is material selection critical for valve seat performance? Ensure Long-Term Reliability and Prevent Leaks

- What industries benefit most from PTFE coatings? Unlock Superior Performance in Demanding Environments