To put it simply, Polytetrafluoroethylene (PTFE) performs exceptionally well when bearing surfaces become contaminated. Unlike many other materials whose performance degrades sharply in the presence of debris, PTFE maintains a remarkably consistent low coefficient of friction. This unique stability makes it a highly reliable choice for real-world applications where cleanliness cannot be guaranteed.

The core challenge with bearing contamination is that debris often mixes with lubricants to form an abrasive slurry, drastically increasing friction and wear. PTFE overcomes this by being inherently self-lubricating, meaning its performance is not dependent on an external fluid that can be compromised.

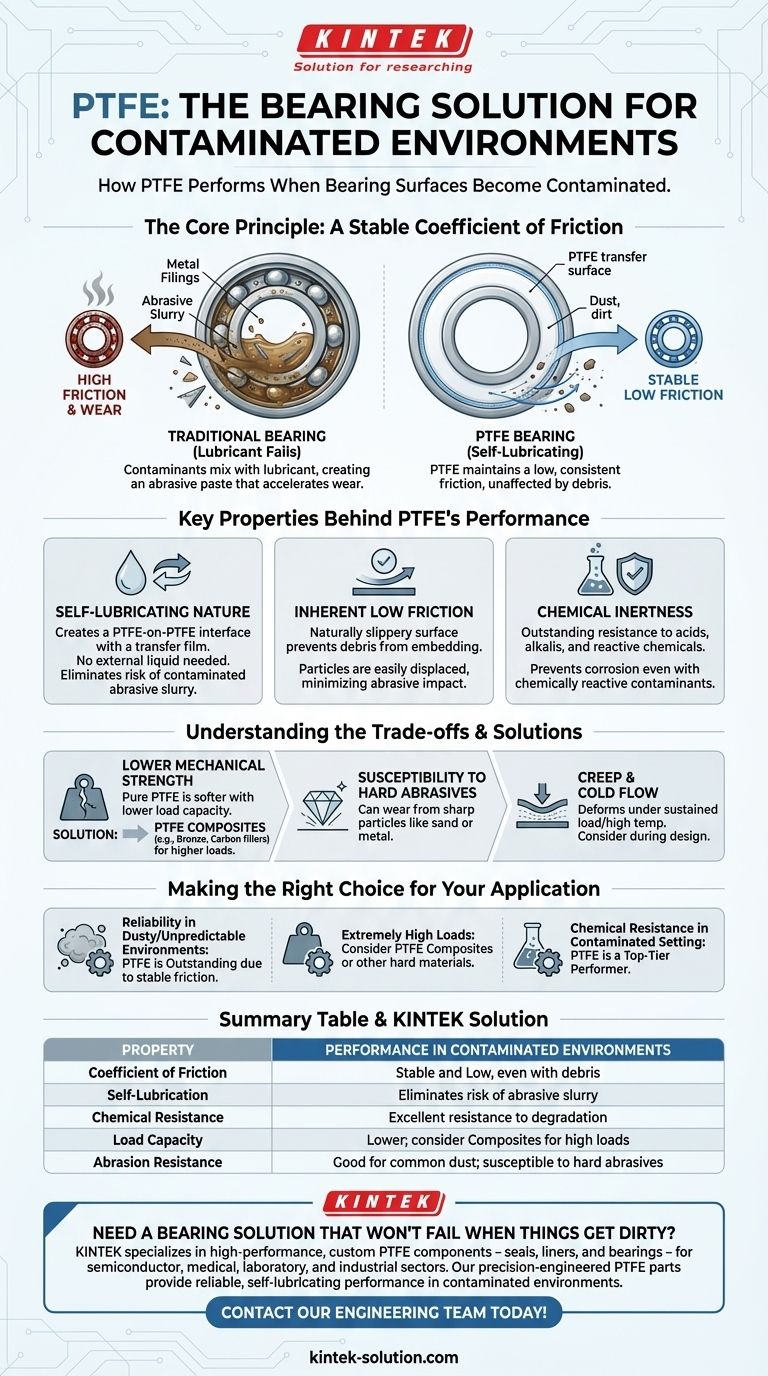

The Core Principle: A Stable Coefficient of Friction

Why Contamination Degrades Performance

In a typical lubricated system, contaminants like dust, dirt, or process byproducts mix with the oil or grease. This mixture turns the lubricant from a protective film into an abrasive paste.

This abrasive action rapidly increases friction, accelerates wear on the bearing surfaces, and can lead to premature equipment failure.

PTFE's Unique Resilience

The defining characteristic of PTFE is its ability to maintain a consistent coefficient of friction even when foreign particles are introduced.

The material's properties are inherent. It does not rely on a clean surface or a pure liquid lubricant to function effectively, providing a predictable and stable performance envelope.

Key Properties Behind PTFE's Performance

Self-Lubricating Nature

PTFE's primary advantage is its self-lubricating quality. A thin film of the material transfers to the mating surface, creating a PTFE-on-PTFE interface.

This mechanism ensures low friction without the need for external liquid lubricants, eliminating the risk of creating an abrasive slurry with contaminants.

Inherent Low Friction

With one of the lowest coefficients of friction of any known solid, PTFE is naturally "slippery."

Debris is less likely to embed itself into the surface or get trapped between moving parts. Instead, particles are more easily displaced, minimizing their abrasive impact.

Chemical Inertness

PTFE offers outstanding resistance to acids, alkalis, and most chemicals.

This means that even if the contamination is chemically reactive, it will not corrode or degrade the PTFE bearing surface, a common failure mode for metals and other plastics.

Understanding the Trade-offs

Lower Mechanical Strength

Pure PTFE is a relatively soft material. It has a lower load-bearing capacity and compressive strength compared to metallic bearings or harder polymers.

For high-load applications, PTFE is often used as a composite, blended with fillers like bronze, carbon, or glass to enhance its mechanical properties.

Susceptibility to Abrasives

While PTFE handles common dust and dirt exceptionally well, it can be susceptible to wear from hard, sharp abrasive particles like sand or metal filings.

These types of contaminants can physically abrade the soft PTFE surface over time, gradually wearing it away.

Creep and Cold Flow

Under a sustained load, especially at elevated temperatures, PTFE can be prone to "creep" or cold flow, where the material slowly deforms.

This must be considered during the design phase to ensure the bearing can handle the application's long-term static and dynamic loads.

Making the Right Choice for Your Application

To determine if PTFE is the correct material, consider the specific demands of your environment.

- If your primary focus is reliability in dusty or unpredictable environments: PTFE is an outstanding choice due to its stable friction and self-lubricating properties.

- If your primary focus is handling extremely high loads: A PTFE composite or a different hard-surface bearing material may be necessary to prevent mechanical failure.

- If your primary focus is chemical resistance in a contaminated setting: PTFE is a top-tier performer, protecting components where traditional lubricants and materials would quickly degrade.

By understanding these principles, you can confidently specify PTFE for applications where consistent performance in imperfect conditions is non-negotiable.

Summary Table:

| Property | Performance in Contaminated Environments |

|---|---|

| Coefficient of Friction | Remains stable and low, even with debris |

| Self-Lubrication | Eliminates risk of abrasive slurry from contaminated lubricants |

| Chemical Resistance | Resists degradation from acids, alkalis, and reactive contaminants |

| Load Capacity | Lower than metals; consider PTFE composites for high loads |

| Abrasion Resistance | Excellent for common dust/dirt; susceptible to hard, sharp abrasives |

Need a bearing solution that won't fail when things get dirty?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and bearings—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE parts provide the reliable, self-lubricating performance you need to maintain operation in contaminated environments, eliminating the risk of failure from compromised lubricants.

We work with you from prototype to high-volume production to ensure a perfect fit for your application's specific demands. Let's discuss how our PTFE expertise can solve your contamination challenges. Contact our engineering team today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications