PTFE-lined plug valves are a cornerstone technology in demanding industrial environments. They are most commonly used in the chemical processing, petrochemical, pharmaceutical, food and beverage, and water treatment industries. The primary reason for their widespread adoption is the exceptional chemical inertness and non-stick properties of the Polytetrafluoroethylene (PTFE) liner, which isolates the process fluid from the valve's metal body.

The decision to use a PTFE-lined plug valve is driven by the need to protect the process fluid from contamination or the valve itself from corrosion. The PTFE liner creates a chemically inert, non-stick barrier, making it the definitive solution for industries where fluid integrity and equipment longevity are critical operational risks.

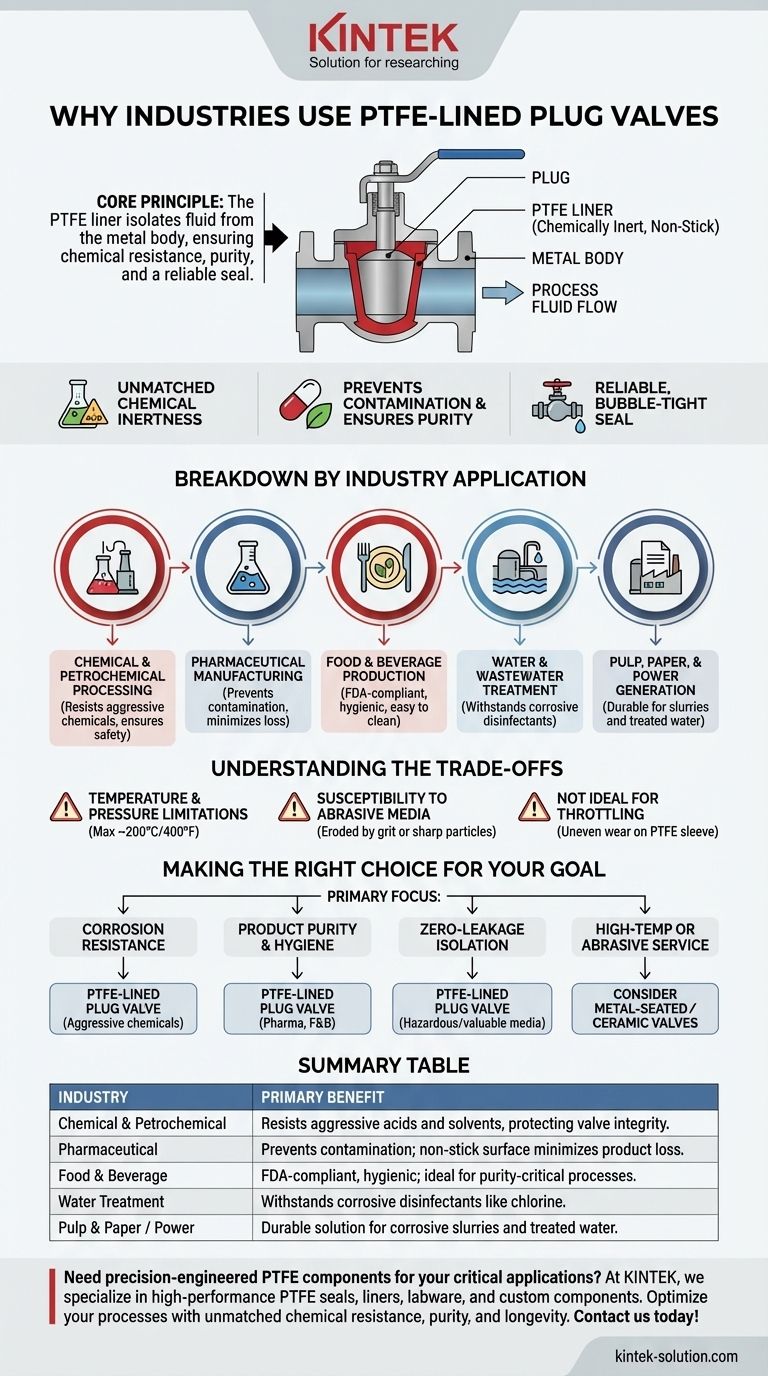

The Core Principle: Why a PTFE Liner is Critical

The value of this valve type is not in the plug mechanism itself, but in the chemically resistant sleeve that encases it. This design solves several fundamental industrial challenges.

Unmatched Chemical Inertness

PTFE is famous for being resistant to nearly all industrial chemicals, acids, solvents, and caustic solutions. This makes it an ideal choice for the harsh environments found in chemical and petrochemical plants. The liner effectively protects the valve's structural metal body (typically ductile iron or stainless steel) from being eaten away by the corrosive media.

Preventing Contamination and Ensuring Purity

The PTFE surface is incredibly smooth and non-porous, a property often described as "non-stick." This is essential in pharmaceutical and food production, where purity is paramount. The liner prevents the product from adhering to the valve surfaces and ensures there is no leaching of metallic ions into the fluid, which could contaminate a sensitive drug or alter the taste of a beverage.

Providing a Reliable, Bubble-Tight Seal

In a lined plug valve, the plug rotates within a soft PTFE sleeve. This design creates an extensive 360° sealing area. When the valve is closed, the sleeve deforms slightly around the plug, creating an exceptionally tight seal that prevents dangerous or valuable fluids from leaking into the environment.

A Breakdown by Industry Application

Different industries leverage these core benefits to solve specific problems.

Chemical and Petrochemical Processing

In this sector, valves must handle a constant flow of aggressive and often hazardous materials. PTFE-lined plug valves provide the necessary corrosion resistance to ensure long service life and, more importantly, plant safety. They prevent leaks of toxic or flammable chemicals.

Pharmaceutical Manufacturing

Product purity is non-negotiable in pharmaceuticals. PTFE-lined valves are specified to prevent the contamination of high-value Active Pharmaceutical Ingredients (APIs). The non-stick surface also minimizes product loss, as the full batch can be processed without leaving valuable material stuck inside the valve.

Food and Beverage Production

Hygiene is the top priority here. PTFE is an FDA-compliant material, meaning it is safe for direct contact with consumables. Its non-stick nature prevents food particles from getting trapped, which simplifies clean-in-place (CIP) procedures and prevents bacterial growth.

Water and Wastewater Treatment

Water treatment facilities use powerful disinfectants like chlorine, sodium hypochlorite, and various acids. A PTFE liner protects the valve body from the long-term corrosive effects of these chemicals, ensuring reliable flow control for many years.

Pulp, Paper, and Power Generation

These industries often handle corrosive bleaching agents, chemical slurries, or treated water. The durability and chemical resistance of PTFE-lined valves make them a reliable and low-maintenance choice for isolation points in these auxiliary processes.

Understanding the Trade-offs

While highly effective, PTFE-lined plug valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Limitations

PTFE has a maximum operating temperature, typically around 200°C (400°F). For applications involving high-temperature steam or other fluids above this threshold, a metal-seated valve is a more appropriate choice. Similarly, their pressure ratings may be lower than those of solid metal valves.

Susceptibility to Abrasive Media

While suitable for some light slurries, the soft PTFE liner can be eroded by highly abrasive or sharp particles over time. In applications with heavy sand, grit, or crystals, a hard-faced metal valve may offer a longer service life.

Not Ideal for Throttling

Plug valves are designed primarily for on/off service (isolation). Using them in a partially open position to regulate flow (throttling) can cause uneven wear on the PTFE sleeve, leading to premature failure of the seal.

Making the Right Choice for Your Goal

To apply this knowledge, consider your primary objective.

- If your primary focus is corrosion resistance: A PTFE-lined plug valve is the default choice for handling aggressive chemicals due to its near-universal inertness.

- If your primary focus is product purity and hygiene: The non-stick, non-leaching properties are essential for any pharmaceutical or food-grade application.

- If your primary focus is zero-leakage isolation: The 360° sealing surface of a lined plug valve provides a superior bubble-tight shutoff for hazardous or valuable media.

- If your primary focus is high-temperature or abrasive service: You should evaluate purpose-built metal-seated or ceramic-lined valves that are designed for these extreme conditions.

By understanding these core principles, you can confidently specify PTFE-lined plug valves where they deliver unmatched safety, purity, and performance.

Summary Table:

| Industry | Primary Benefit of PTFE Liner |

|---|---|

| Chemical & Petrochemical | Resists aggressive acids and solvents, protecting valve integrity. |

| Pharmaceutical | Prevents contamination of sensitive drugs; non-stick surface minimizes product loss. |

| Food & Beverage | FDA-compliant, hygienic, and easy to clean; ideal for purity-critical processes. |

| Water Treatment | Withstands corrosive disinfectants like chlorine, ensuring long-term reliability. |

| Pulp & Paper / Power | Durable solution for handling corrosive slurries and treated water. |

Need precision-engineered PTFE components for your critical applications? At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with unmatched chemical resistance, purity, and longevity—from prototypes to high-volume orders. Contact us today to discuss how our solutions can optimize your processes!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is a PTFE bush and what is its primary use? A Guide to Self-Lubricating Bearings

- What are the two main methods for producing PTFE? Choose the Right Path for Your Application

- What are the advantages of Polytetrafluoroethylene (PTFE) with Graphite Fill? Enhance Wear and Friction Performance

- What are the key properties of PTFE that make it suitable for diaphragms? Unlock Superior Chemical & Thermal Resistance

- What advantages do PTFE washers offer? Superior Chemical, Thermal, and Low-Friction Performance

- What are the best practices for precision PTFE machining? Master the Finesse for Flawless Components

- What are the electrical and electronic applications of PTFE? High-Performance Insulation for Demanding Environments

- What benefits do PTFE lined pipes offer in terms of chemical flow? Ensure Corrosion-Free, High-Purity Transfer