At its core, PTFE lined pipe dramatically improves chemical flow by providing an exceptionally non-stick and low-friction surface. This slick, chemically inert lining allows fluids to move with minimal resistance, preventing buildup and ensuring a consistent, efficient transfer process.

Transporting aggressive or high-purity chemicals presents a constant battle against corrosion, contamination, and inefficiency. The fundamental benefit of a PTFE lining is not just improved flow, but the creation of an inert barrier that protects the entire system, ensuring operational longevity, product purity, and long-term financial viability.

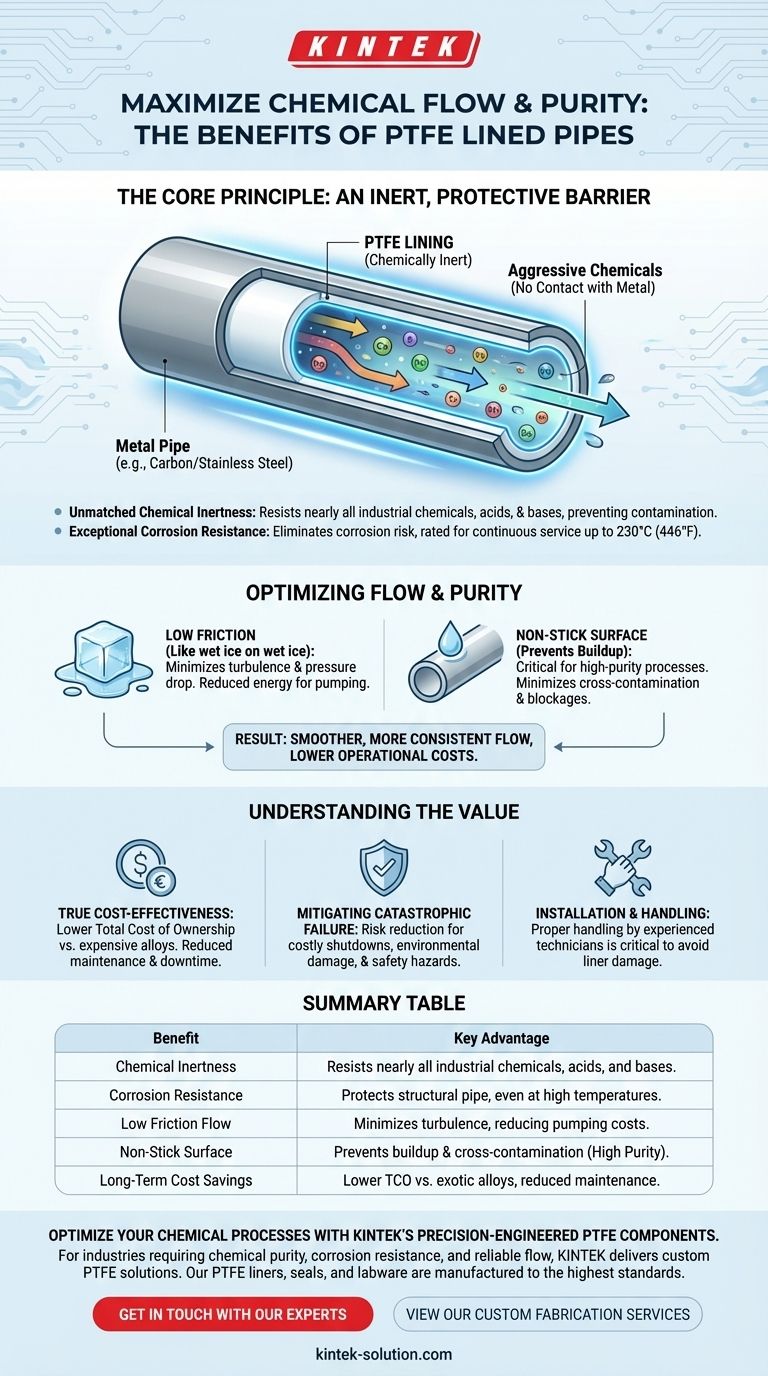

The Core Principle: An Inert, Protective Barrier

The primary function of a PTFE lining is to separate the conveyed chemical from the structural outer pipe, typically made of carbon or stainless steel. This creates a system that combines the mechanical strength of metal with the unique properties of PTFE.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is effectively inert to nearly all industrial chemicals, acids, and bases, regardless of their concentration.

This means the lining will not react with the fluid it is carrying, preventing both degradation of the pipe and contamination of the chemical. The only known exceptions are molten alkali metals and highly reactive fluorinating agents.

Exceptional Corrosion Resistance

Because the chemical never touches the outer metal pipe, the risk of corrosion is virtually eliminated. This protection holds true across a very wide temperature range, with many systems rated for continuous service up to 230°C (446°F).

This allows for the safe transport of highly corrosive substances that would rapidly destroy unlined metal pipes, even at high temperatures and pressures.

Optimizing Flow and Purity

Beyond simply protecting the pipe, the PTFE surface has a profound impact on the fluid dynamics and the quality of the product being moved.

The Impact of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, similar to wet ice on wet ice. This "slippery" surface minimizes turbulence and pressure drop within the pipeline.

The practical result is a smoother, more consistent flow that often requires less energy for pumping, leading to lower operational costs.

Preventing Buildup and Contamination

The non-stick nature of PTFE prevents materials from adhering to the pipe wall. This is critical in processes where purity is paramount, such as in pharmaceutical or semiconductor manufacturing, as it minimizes cross-contamination between batches.

It also prevents the buildup of deposits that could otherwise restrict flow, foul the system, or break off and contaminate the final product.

Understanding the Trade-offs and Value

While highly effective, it's important to view PTFE lined pipe as an engineered solution with specific advantages and considerations, not as a universal fix for every application.

The True Cost-Effectiveness

A PTFE lined piping system is a more cost-effective long-term solution than using pipes made entirely from expensive specialty alloys like Hastelloy or titanium.

While the initial investment may be higher than for simple steel pipe, the total cost of ownership is significantly lower due to reduced maintenance, minimal downtime, and a drastically extended service life.

Mitigating Catastrophic Failure

The most significant value is in risk reduction. A failure in a line carrying aggressive chemicals can lead to costly shutdowns, environmental damage, and severe safety hazards for personnel.

The reliability of a properly installed PTFE lined system provides a robust defense against these catastrophic events, safeguarding both people and profits.

Installation and Handling

The primary vulnerability of a lined pipe system is mechanical damage to the liner before or during installation. A deep scratch or gouge can create a pathway for chemicals to attack the outer pipe.

Therefore, proper handling, inspection, and installation by experienced technicians are critical to realizing the full lifespan and safety benefits of the system.

Making the Right Choice for Your Application

Selecting the right piping system requires aligning its capabilities with your primary operational goals.

- If your primary focus is handling highly corrosive chemicals: PTFE lining offers unparalleled protection for your structural piping, ensuring system integrity and longevity even in the most aggressive services.

- If your primary focus is maintaining product purity: The inert, non-stick surface of PTFE is the ideal choice to prevent leaching and contamination, safeguarding the value of your high-purity product.

- If your primary focus is long-term cost reduction: PTFE lined pipe provides a superior total cost of ownership by eliminating corrosion-related maintenance, downtime, and the need for expensive exotic alloy piping.

Ultimately, choosing a PTFE lined system is an investment in the long-term reliability and safety of your critical chemical processes.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases, preventing contamination. |

| Corrosion Resistance | Protects structural pipe from aggressive substances, even at high temperatures (up to 230°C). |

| Low Friction Flow | Minimizes turbulence and pressure drop, reducing pumping energy and costs. |

| Non-Stick Surface | Prevents buildup and cross-contamination, ideal for high-purity applications. |

| Long-Term Cost Savings | Lower total cost of ownership vs. exotic alloys, with reduced maintenance and downtime. |

Optimize your chemical processes with KINTEK's precision-engineered PTFE components.

For industries where chemical purity, corrosion resistance, and reliable flow are non-negotiable—such as semiconductor manufacturing, pharmaceuticals, and industrial chemical handling—KINTEK delivers custom PTFE solutions that protect your product and your bottom line. Our PTFE liners, seals, and labware are manufactured to the highest standards, ensuring unmatched inertness and durability.

We specialize in custom fabrication, from initial prototypes to high-volume production, tailored to your specific application requirements.

Contact us today to discuss how our PTFE expertise can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability