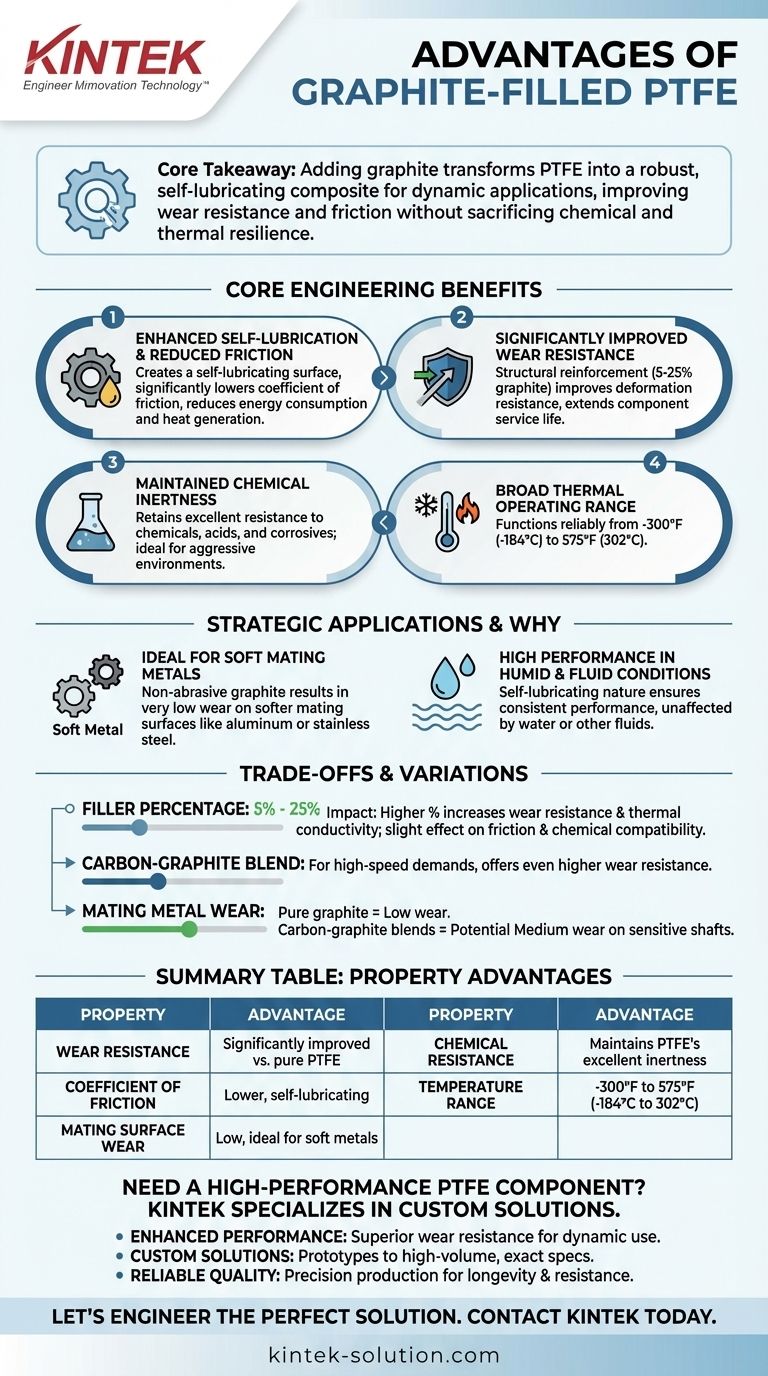

The primary advantages of Polytetrafluoroethylene (PTFE) with graphite fill are significantly improved wear resistance and a lower coefficient of friction. By adding graphite, the base PTFE material is transformed into a self-lubricating composite ideal for dynamic applications. This blend maintains PTFE's excellent chemical inertness and wide temperature range while adding the mechanical strength needed for demanding sealing and bearing roles, especially in wet conditions.

The core takeaway is that adding graphite to PTFE is an engineering solution to overcome the inherent softness of pure PTFE. It creates a robust, self-lubricating material that excels in moving applications without sacrificing the chemical and thermal resistance that makes PTFE valuable.

The Core Engineering Benefits of Graphite Filler

Adding graphite as a filler fundamentally enhances the mechanical properties of PTFE, making it suitable for a much broader range of applications, particularly those involving motion and friction.

Enhanced Self-Lubrication and Reduced Friction

Graphite is a well-known solid lubricant. Its inclusion in the PTFE matrix creates a self-lubricating surface.

This drastically lowers the coefficient of friction, which reduces both the energy required for movement and the heat generated in dynamic seals or bearings.

Significantly Improved Wear Resistance

Pure PTFE is a relatively soft material prone to deformation and cold flow under load.

Adding graphite (typically 5-25%) provides structural reinforcement, which improves deformation resistance and strength. This results in a material with very good wear characteristics, extending the service life of components.

Maintained Chemical Inertness

One of the most prized properties of PTFE is its resistance to nearly all chemicals, acids, and corrosive substances.

Graphite is also highly inert, meaning that graphite-filled PTFE maintains this exceptional chemical compatibility. This makes it a prime choice for sealing applications in aggressive chemical environments.

Broad Thermal Operating Range

Graphite-filled PTFE functions reliably across an extremely wide temperature spectrum.

The material can operate effectively in cryogenic conditions as low as -300°F (-184°C) and in high-heat environments up to 575°F (302°C).

Why Graphite Is a Strategic Choice for Applications

The unique properties of this composite material make it an optimal solution for specific engineering challenges, particularly when dealing with sensitive surfaces or fluid dynamics.

Ideal for Soft Mating Metals

Unlike harder fillers like glass or carbon fiber, graphite is not highly abrasive.

This makes it an excellent choice for applications where the seal or bearing runs against softer metals like aluminum or stainless steel, as it causes very low wear on the mating surface.

High Performance in Humid and Fluid Applications

The material shows exceptionally good performance in humid conditions and fluid applications.

Its self-lubricating nature is not dependent on external lubrication and is not compromised by the presence of water or other fluids, ensuring consistent performance.

Understanding the Trade-offs and Variations

While graphite-filled PTFE is an excellent material, its properties can be further tailored by blending it with other fillers, which introduces important trade-offs.

The Role of Filler Percentage

The amount of graphite filler, typically between 5% and 25%, directly impacts the final properties.

Higher percentages generally increase wear resistance and thermal conductivity but may slightly alter the coefficient of friction and chemical compatibility in extreme cases.

Blending with Carbon for Higher Demands

For the most demanding high-speed applications, a carbon-graphite fill is often used.

This combination creates one of the best wear materials for high-speed rotary and reciprocating components, offering an even higher wear resistance rating than graphite alone.

A Note on Mating Metal Wear

The primary trade-off with carbon-graphite blends is a potential increase in abrasiveness. While pure graphite fill offers low mating metal wear, some premium carbon-graphite blends can cause medium mating metal wear, a critical consideration when designing for sensitive or expensive shafts.

Making the Right Choice for Your Application

Selecting the correct material composition is critical for ensuring the reliability and longevity of your components.

- If your primary focus is reducing friction against soft metal surfaces: Standard graphite-filled PTFE is the ideal choice due to its non-abrasive, self-lubricating properties.

- If you are designing for high-speed rotary or reciprocating applications: A carbon-graphite filled PTFE will provide the superior wear resistance needed for longevity under intense conditions.

- If your application involves sealing aggressive chemicals in wet conditions: The excellent chemical inertness and hydrophobic nature of graphite-filled PTFE make it a reliable and long-lasting solution.

Ultimately, choosing the right filled PTFE ensures your components operate with maximum efficiency and minimal wear.

Summary Table:

| Property | Advantage of Graphite-Filled PTFE |

|---|---|

| Wear Resistance | Significantly improved vs. pure PTFE |

| Coefficient of Friction | Lower, self-lubricating |

| Chemical Resistance | Maintains PTFE's excellent inertness |

| Temperature Range | -300°F to 575°F (-184°C to 302°C) |

| Mating Surface Wear | Low, ideal for soft metals |

Need a High-Performance PTFE Component?

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, the right material choice is critical. KINTEK specializes in the precision manufacturing of custom PTFE components, including graphite-filled and carbon-graphite blends.

We deliver:

- Enhanced Performance: Components with superior wear resistance and self-lubrication for dynamic applications.

- Custom Solutions: Expert fabrication from prototypes to high-volume orders to meet your exact specifications.

- Reliable Quality: Precision production ensuring longevity and chemical resistance in harsh environments.

Let's engineer the perfect solution for your application. Contact KINTEK today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications