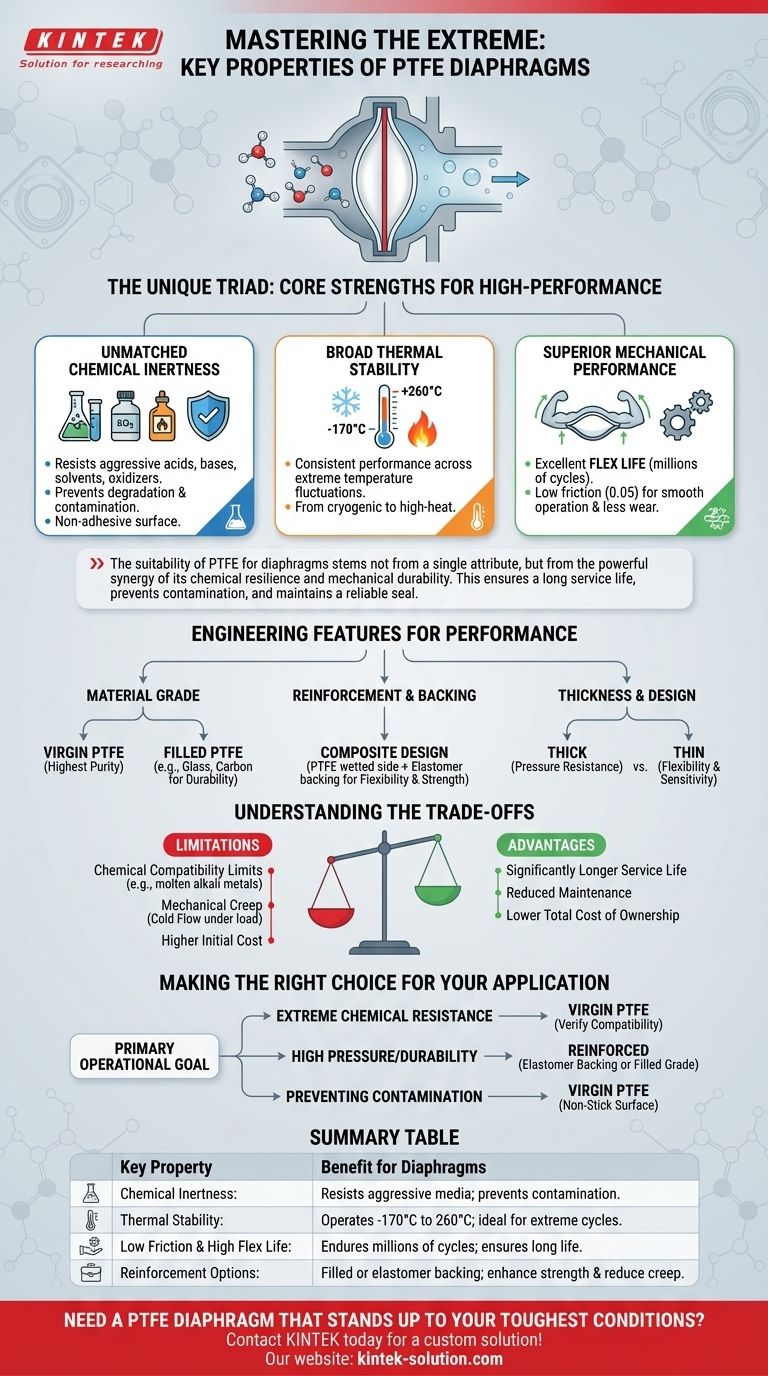

At its core, Polytetrafluoroethylene (PTFE) is the material of choice for high-performance diaphragms due to a unique triad of properties: near-universal chemical inertness, exceptional thermal stability, and a very low coefficient of friction. This combination allows PTFE diaphragms to function reliably as flexible barriers in aggressive chemical and high-temperature environments where most other materials would rapidly degrade and fail.

The suitability of PTFE for diaphragms stems not from a single attribute, but from the powerful synergy of its chemical resilience and mechanical durability. This ensures a long service life, prevents contamination, and maintains a reliable seal under demanding operational conditions.

The Foundational Properties of PTFE Diaphragms

To understand why PTFE is so effective, we must look at its specific material characteristics. These properties work in concert to deliver superior performance as a sealing and separating membrane.

Unmatched Chemical Inertness

PTFE is famously resistant to a vast range of chemicals, including aggressive acids, bases, solvents, and oxidizers. This inertness means the diaphragm does not swell, weaken, or degrade when exposed to harsh media.

Its non-adhesive surface also prevents material buildup and reduces the risk of process contamination, which is critical in high-purity applications.

Broad Thermal Stability

PTFE diaphragms can operate effectively across an exceptionally wide temperature range, typically from -170°C to over 260°C (-250°F to 500°F).

This stability ensures consistent mechanical performance and sealing integrity in systems that experience extreme temperature fluctuations, from cryogenic applications to high-heat industrial processes.

Superior Mechanical Performance

A diaphragm must flex repeatedly without cracking or failing. PTFE exhibits an excellent flex life, allowing it to endure millions of cycles without fatigue.

Furthermore, its low coefficient of friction (as low as 0.05) means less wear and smoother operation, especially in dynamic applications like pumps and valves.

Key Engineering Features for Performance

The base properties of PTFE are often enhanced through specific manufacturing and design choices to tailor performance for a given application.

Material Grade (Virgin vs. Filled)

Virgin PTFE offers the highest purity and broadest chemical resistance. For applications requiring greater mechanical strength or wear resistance, filled PTFE grades (which include agents like glass or carbon) are used to improve durability and reduce material creep under load.

Reinforcement and Backing

Many PTFE diaphragms are not used alone. They are often bonded to a more flexible rubber or elastomer backing.

This composite design combines the chemical resistance of the PTFE "wetted" side with the strength and resilience of the rubber backing, creating a diaphragm that is both durable and highly flexible.

Thickness and Design

The thickness of the PTFE layer is a critical design parameter. A thicker diaphragm provides greater pressure resistance and permeation resistance, while a thinner layer offers increased flexibility and sensitivity, which is vital for regulator or control applications.

Understanding the Trade-offs

While highly capable, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Chemical Compatibility Limits

Despite its broad resistance, PTFE is not completely immune to all substances. It can be attacked by highly reactive media like molten alkali metals and certain complex halogenated compounds.

Always verify material compatibility with the specific chemicals in your system before selection.

Mechanical Considerations

Unfilled, or virgin, PTFE can be susceptible to "creep" or cold flow under a constant, high mechanical load. This can lead to a loss of sealing pressure over time.

For high-pressure applications or where constant torque is applied, a filled-grade or elastomer-backed PTFE diaphragm is often a more reliable choice.

Cost vs. Total Cost of Ownership

PTFE components can have a higher initial cost compared to some standard elastomers.

However, their significantly longer service life, reduced maintenance requirements, and prevention of costly failures in aggressive environments often result in a much lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the optimal diaphragm requires matching its features to your primary operational goal.

- If your primary focus is extreme chemical resistance: Prioritize a virgin PTFE diaphragm for its purity and broad inertness, but always verify compatibility with your specific media.

- If your primary focus is high pressure or mechanical durability: Select a reinforced diaphragm with an elastomer backing or a filled-grade PTFE to improve strength and reduce material creep.

- If your primary focus is preventing process contamination: The non-stick, non-adhesive surface of virgin PTFE is ideal for food-grade, pharmaceutical, or semiconductor applications.

Ultimately, selecting the correct PTFE diaphragm comes down to matching its unique combination of chemical, thermal, and mechanical properties to the precise demands of your operating environment.

Summary Table:

| Key Property | Benefit for Diaphragms |

|---|---|

| Chemical Inertness | Resists aggressive acids, bases, solvents; prevents contamination. |

| Thermal Stability | Operates from -170°C to 260°C; ideal for extreme temperature cycles. |

| Low Friction & High Flex Life | Endures millions of cycles with minimal wear; ensures long service life. |

| Reinforcement Options | Filled grades (glass, carbon) or elastomer backing enhance strength and reduce creep. |

Need a PTFE diaphragm that stands up to your toughest conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom diaphragms for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures you get a diaphragm that delivers:

- Reliable performance in aggressive chemical and high-temperature environments.

- Long service life with superior flex life and low friction.

- Custom solutions tailored to your specific pressure, temperature, and media requirements.

Let us help you optimize your system's reliability and efficiency. Contact KINTEK today for a custom PTFE diaphragm solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE's chemical resistance contribute to its medical applications? Ensuring Biocompatibility and Sterilization Safety

- What are filled PTFE bushes and why are fillers added? Enhance Wear Resistance & Load Capacity

- What are the benefits of virgin PTFE in medical devices? Ensure Biocompatibility and Safety

- Why is PTFE difficult to process using traditional methods? Overcoming High Melt Viscosity

- What are the key properties of PTFE guide strips? Ensure Low-Friction, High-Temp Performance

- Are PTFE and PEEK backup rings usually pure, or do they contain fillers? Discover the Role of Fillers in High-Performance Seals

- What materials can Expanded PTFE replace in specific applications? A Guide to Simplifying Your Sealing Inventory

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components