In short, the key properties of PTFE (Polytetrafluoroethylene) guide strips are their extremely low coefficient of friction, exceptional chemical inertness, and a very wide operating temperature range. These characteristics make them ideal for creating smooth, durable, and non-reactive bearing surfaces in demanding mechanical systems.

PTFE guide strips are not simply pieces of plastic; they are high-performance engineering components designed to solve a specific problem: preventing metal-on-metal contact in moving parts. Their value lies in a unique combination of properties that ensures operational efficiency and extends the life of machinery, especially under harsh conditions.

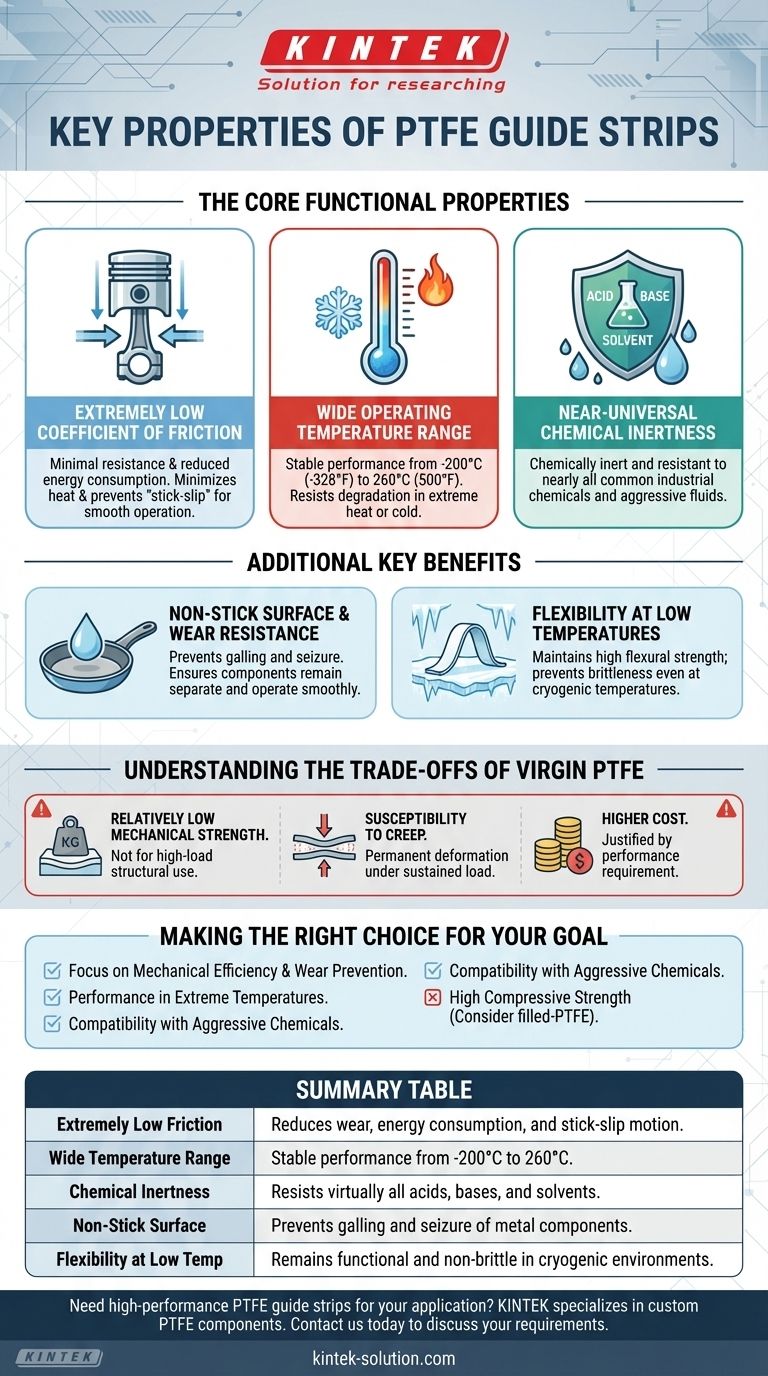

The Core Functional Properties of PTFE

At its heart, a guide strip serves to guide a moving component, like a piston in a cylinder, while preventing wear. The properties of PTFE are almost perfectly suited for this role.

Mechanical Performance: The Key to Low Wear

The primary function of a guide strip is mechanical. PTFE’s properties directly contribute to low-friction, long-lasting performance.

Extremely Low Coefficient of Friction PTFE has one of the lowest coefficients of friction of any known solid. This means parts slide against it with minimal resistance.

This property directly reduces the energy required to move components, minimizes heat generation from friction, and prevents the "stick-slip" motion that can cause vibration and wear.

Wear Resistance and Non-Stick Surface While relatively soft, PTFE is wear-resistant in bearing applications and has a famous non-stick surface.

This prevents galling and seizure between moving metal parts, ensuring components remain separate and operate smoothly over millions of cycles.

Flexibility at Low Temperatures PTFE maintains its high flexural strength even at cryogenic temperatures (down to -200°C / -328°F). This prevents it from becoming brittle and fracturing in cold environments.

Thermal Stability: Performance Under Extreme Heat and Cold

Temperature fluctuations can cause many materials to fail, but PTFE maintains its integrity across an exceptionally broad range.

Wide Operating Temperature Range PTFE is stable for continuous service from approximately -200°C (-328°F) to 260°C (500°F).

This allows PTFE guide strips to be used in everything from cryogenic pumps to high-temperature hydraulic systems without degrading, melting, or becoming brittle.

Non-Flammability PTFE has a very high melting point of around 327°C (621°F) and will not support a flame. This adds a critical layer of safety in high-temperature applications.

Chemical and Environmental Resistance

Many mechanical systems operate in the presence of aggressive fluids or harsh environmental conditions.

Near-Universal Chemical Inertness PTFE is chemically inert and resistant to nearly all common industrial chemicals, solvents, acids, and bases.

This makes it the material of choice for hydraulic and pneumatic seals and guides where it may come into contact with aggressive hydraulic fluids, cleaning agents, or corrosive substances.

Moisture and Weather Resistance The material is hydrophobic, meaning it repels water and does not absorb moisture. It is also completely resistant to UV light, ozone, and general weathering.

This ensures its properties do not change over time due to environmental exposure, making it suitable for outdoor or long-life applications.

Understanding the Trade-offs of Virgin PTFE

No material is perfect. While PTFE’s properties are outstanding, it's crucial to understand its limitations for proper application design.

Relatively Low Mechanical Strength

Virgin PTFE is a relatively soft material. It is not designed for high-load structural applications.

Its purpose is to provide a low-friction bearing surface, not to bear significant structural or compressive loads on its own. For higher loads, filled grades of PTFE (e.g., bronze-filled or carbon-filled) are often used to improve compressive strength and wear resistance.

Susceptibility to Creep

Like many polymers, PTFE can be subject to "creep"—a slow, permanent deformation under a sustained load.

This must be accounted for in design calculations, especially in applications with constant high pressure, to ensure dimensional stability over the product's lifetime.

Higher Cost Compared to Commodity Plastics

PTFE is a high-performance fluoropolymer and is more expensive than common plastics like nylon or polyethylene.

Its use is justified by performance requirements that other materials cannot meet, such as extreme temperatures or chemical exposure, where failure would be far more costly.

Making the Right Choice for Your Goal

When selecting a guide strip material, your primary objective will determine if PTFE is the correct choice.

- If your primary focus is mechanical efficiency and preventing wear: PTFE is an exceptional choice due to its unparalleled low-friction surface.

- If your primary focus is performance in extreme temperatures: PTFE's vast operating temperature range makes it one of the most reliable options available.

- If your primary focus is compatibility with aggressive chemicals: PTFE's chemical inertness ensures it will not degrade when exposed to most industrial fluids.

- If your primary focus is high compressive strength: You should evaluate filled-PTFE grades or alternative materials like bronze, as virgin PTFE is relatively soft.

Ultimately, choosing PTFE is a decision to prioritize reliability and performance in challenging operational environments.

Summary Table:

| Key Property | Benefit for Guide Strips |

|---|---|

| Extremely Low Friction | Reduces wear, energy consumption, and stick-slip motion. |

| Wide Temperature Range | Stable performance from -200°C to 260°C. |

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Non-Stick Surface | Prevents galling and seizure of metal components. |

| Flexibility at Low Temp | Remains functional and non-brittle in cryogenic environments. |

Need high-performance PTFE guide strips for your application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including guide strips, seals, liners, and labware. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures a solution that delivers superior low-friction performance, exceptional chemical resistance, and reliability in extreme temperatures.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application