At its core, Polytetrafluoroethylene's (PTFE) renowned chemical resistance is the primary reason for its value in medical applications. This property ensures that medical devices remain structurally sound, non-reactive, and safe when exposed to the chemically aggressive environment of the human body and the harsh chemicals used for sterilization.

The true significance of PTFE's chemical resistance in medicine is not merely its durability, but its role as a foundation for biocompatibility. Its inability to react chemically ensures it will not degrade within the body, leach harmful substances, or trigger an adverse immune response.

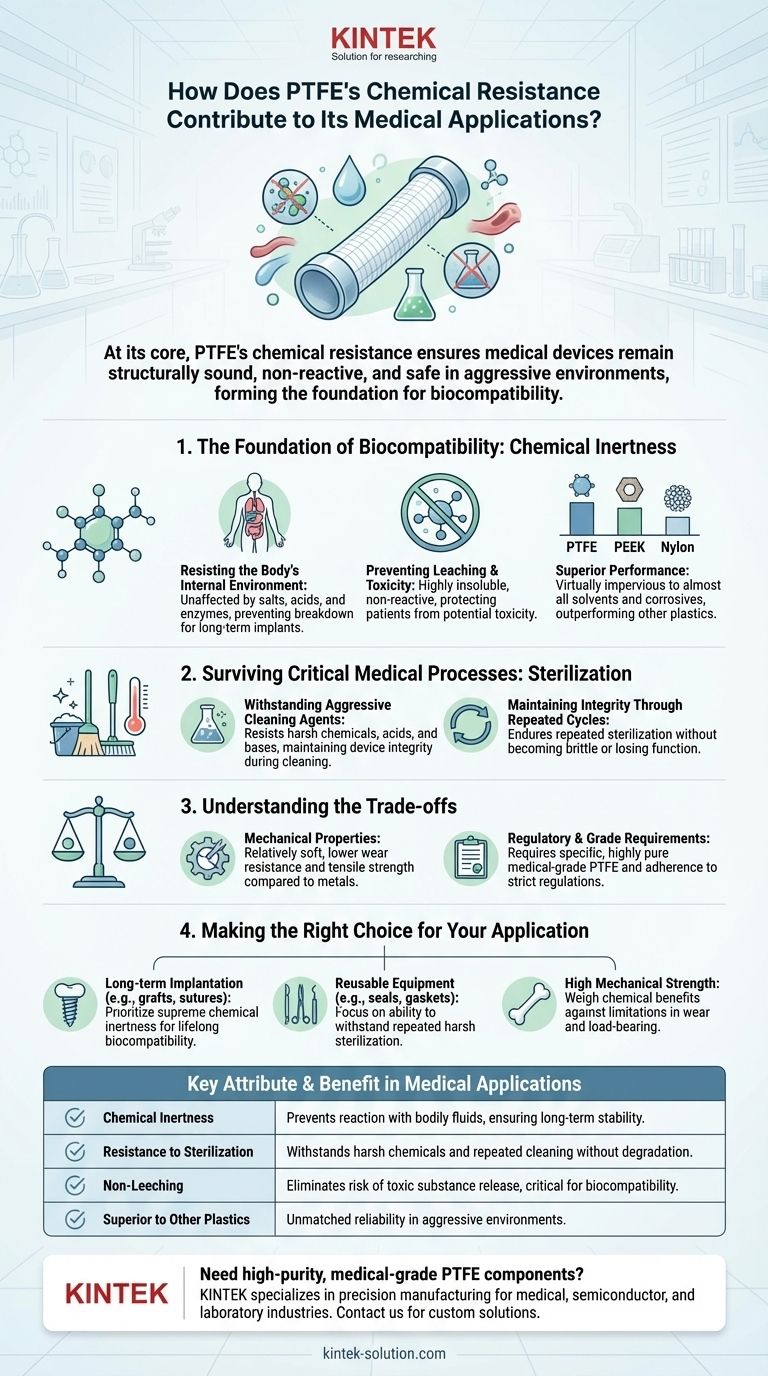

The Foundation of Biocompatibility: Chemical Inertness

For any material to be considered safe for use inside the human body, it must be biocompatible. PTFE's extreme chemical inertness is the key to achieving this standard.

Resisting the Body's Internal Environment

The human body is a complex environment filled with salts, acids, and enzymes that can corrode or degrade lesser materials. PTFE is almost completely unaffected by these biological fluids.

This non-reactivity prevents the material from breaking down over time, which is critical for long-term implants such as vascular grafts.

Preventing Leaching and Toxicity

A direct consequence of being chemically inert is that PTFE is highly insoluble. It does not dissolve or leach chemicals into the surrounding tissue or bloodstream.

This lack of leaching is a fundamental safety requirement for any implantable device, protecting the patient from potential toxicity.

Superior Performance Over Other Plastics

PTFE's chemical resistance significantly outperforms other high-performance plastics like PEEK or Nylon. It is virtually impervious to almost all industrial solvents and corrosive substances, making it a uniquely reliable choice for critical applications.

Surviving Critical Medical Processes: Sterilization

Beyond its performance inside the body, a medical material must withstand the rigorous processes required to prepare it for use.

Withstanding Aggressive Cleaning Agents

Medical and surgical equipment must be sterilized to prevent infection. This often involves exposure to harsh chemicals, acids, bases, and high temperatures.

PTFE’s ability to resist these substances ensures that devices—from O-rings in equipment to surgical fasteners—do not degrade, crack, or lose their function during cleaning.

Maintaining Integrity Through Repeated Cycles

Many medical instruments are reusable. PTFE components can endure repeated sterilization cycles without becoming brittle or changing their physical properties. This reliability is essential for the consistent performance and safety of medical tools.

Understanding the Trade-offs

While its chemical resistance is unparalleled, PTFE is not a universal solution for every medical challenge. A clear-eyed assessment of its limitations is crucial.

Mechanical Properties

PTFE is a relatively soft material with lower wear resistance and tensile strength compared to metals or other specialized polymers. This makes it unsuitable for high-load applications like orthopedic joint replacements.

Regulatory and Grade Requirements

Not all PTFE is created equal. Medical applications demand specific, highly pure medical-grade PTFE. There are strict regulations governing its use in medical devices, and these requirements must be consulted for any specific application.

Making the Right Choice for Your Application

The decision to use PTFE should be driven by the primary demands of the medical device in question.

- If your primary focus is long-term implantation (e.g., vascular grafts, sutures): PTFE's supreme chemical inertness is the most critical factor, ensuring lifelong biocompatibility and stability.

- If your primary focus is reusable equipment (e.g., seals, gaskets, tool components): PTFE's ability to withstand repeated, harsh chemical sterilization without degrading is its key advantage.

- If your primary focus is a device requiring high mechanical strength: You must carefully weigh if PTFE’s chemical benefits outweigh its limitations in wear and load-bearing capacity.

Ultimately, PTFE's profound chemical stability is the cornerstone of its safety and reliability in demanding medical environments.

Summary Table:

| Key Attribute | Benefit in Medical Applications |

|---|---|

| Chemical Inertness | Prevents reaction with bodily fluids, ensuring long-term implant stability and safety. |

| Resistance to Sterilization | Withstands harsh chemicals and repeated cleaning cycles without degradation. |

| Non-Leeching | Eliminates risk of toxic substance release into the body, critical for biocompatibility. |

| Superior to Other Plastics | Offers unmatched reliability in aggressive environments compared to materials like PEEK or Nylon. |

Need high-purity, medical-grade PTFE components for your critical applications?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and custom labware for the medical, semiconductor, and laboratory industries. Our components are engineered to meet stringent regulatory standards, ensuring biocompatibility and durability for implants, surgical tools, and sterilization-resistant equipment.

Let us help you enhance device safety and performance—contact our experts today for custom solutions from prototypes to high-volume orders!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials