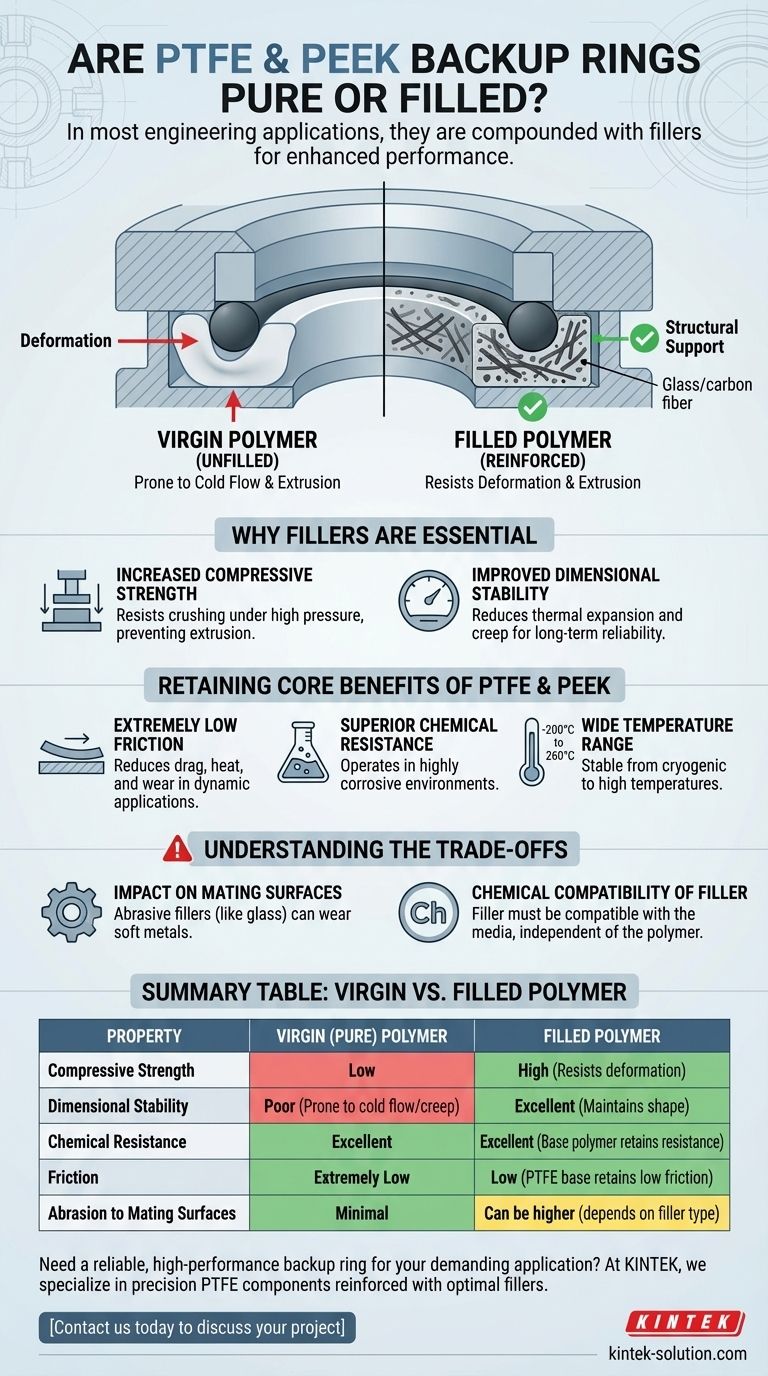

In most engineering applications, PTFE and PEEK backup rings are not pure. They are almost always compounded with fillers like glass or carbon fiber to improve the material's mechanical properties, specifically its ability to resist deformation and extrusion under high pressure.

The core function of a backup ring is to provide structural support and prevent an O-ring from extruding into the clearance gap of a high-pressure seal. While virgin PTFE and PEEK have desirable low-friction and chemical-resistant properties, they lack the raw compressive strength and dimensional stability required for this task; fillers are the critical addition that makes them suitable for demanding sealing applications.

Why Fillers Are Essential

Unfilled, or "virgin," polymers often cannot meet the intense mechanical demands placed on a backup ring. The addition of specific fillers directly addresses their inherent weaknesses.

The Problem: Extrusion and Deformation

In a high-pressure system, the O-ring is pushed against the backup ring. The backup ring must hold its shape precisely to close the extrusion gap and support the seal.

Virgin polymers, particularly PTFE, are susceptible to "cold flow" or creep—a tendency to deform permanently when subjected to sustained pressure. This deformation compromises the seal and leads to failure.

The Solution: Enhanced Mechanical Properties

Fillers act as a reinforcement within the polymer matrix, much like rebar strengthens concrete. This reinforcement provides two primary benefits.

It increases compressive strength, which is the material's ability to resist being crushed. This is the single most important factor in preventing the O-ring and backup ring from being forced into the clearance gap.

It improves dimensional stability by reducing thermal expansion and minimizing creep under load. A filled backup ring maintains its precise shape and size across a range of temperatures and pressures, ensuring a reliable seal over time.

Retaining the Core Benefits of PTFE and PEEK

Crucially, the addition of fillers enhances mechanical strength without sacrificing the base polymer's most valuable characteristics.

Extremely Low Friction

Even when filled, PTFE retains an exceptionally low coefficient of friction. This is vital in dynamic sealing applications where it reduces drag, heat generation, and wear on moving parts.

Superior Chemical Resistance

PTFE and PEEK are renowned for their chemical inertness. They can operate in highly corrosive environments where other materials would quickly degrade, making them ideal for chemically aggressive processes.

Wide Temperature Range

PTFE, in particular, has an outstanding functional temperature range, remaining stable from cryogenic conditions (-200°C) up to high temperatures (260°C). This allows these backup rings to perform reliably in extreme thermal environments.

Understanding the Trade-offs

While fillers are overwhelmingly beneficial for backup rings, they do introduce considerations that are important for material selection.

Impact on Mating Surfaces

Some fillers, like glass fiber, can be more abrasive than the virgin polymer. In dynamic applications with soft metal shafts or bores, the choice of filler must be carefully considered to prevent premature wear on hardware.

Chemical Compatibility of the Filler

While the base polymer may be resistant to a specific chemical, the filler may not be. For example, glass fillers can be attacked by certain aggressive chemicals, compromising the integrity of the backup ring even if the PTFE or PEEK matrix remains unaffected.

Making the Right Choice for Your Application

Selecting the correct backup ring material requires matching the properties of the filled compound to the specific demands of your system.

- If your primary focus is extreme pressure resistance: A filled PTFE or PEEK is non-negotiable, as the fillers provide the essential compressive strength and anti-extrusion properties.

- If your primary focus is compatibility with aggressive chemicals: The inherent resistance of a PTFE or PEEK base is your starting point, but you must also verify that the chosen filler is compatible with your media.

- If your primary focus is reducing friction in a dynamic system: The naturally low-friction properties of PTFE make it the superior choice, with fillers added to ensure it can withstand the system's pressure.

Ultimately, fillers are the key ingredient that transforms these versatile polymers into high-performance backup rings engineered for reliability.

Summary Table:

| Property | Virgin (Pure) Polymer | Filled Polymer |

|---|---|---|

| Compressive Strength | Low | High (Resists deformation under pressure) |

| Dimensional Stability | Poor (Prone to cold flow/creep) | Excellent (Maintains shape under load) |

| Chemical Resistance | Excellent | Excellent (Base polymer retains resistance) |

| Friction | Extremely Low | Low (PTFE base retains low friction) |

| Abrasion to Mating Surfaces | Minimal | Can be higher (depends on filler type) |

Need a reliable, high-performance backup ring for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom backup rings reinforced with the optimal fillers for your specific needs. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your seals can withstand extreme pressures, corrosive chemicals, and wide temperature ranges.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and performance.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications