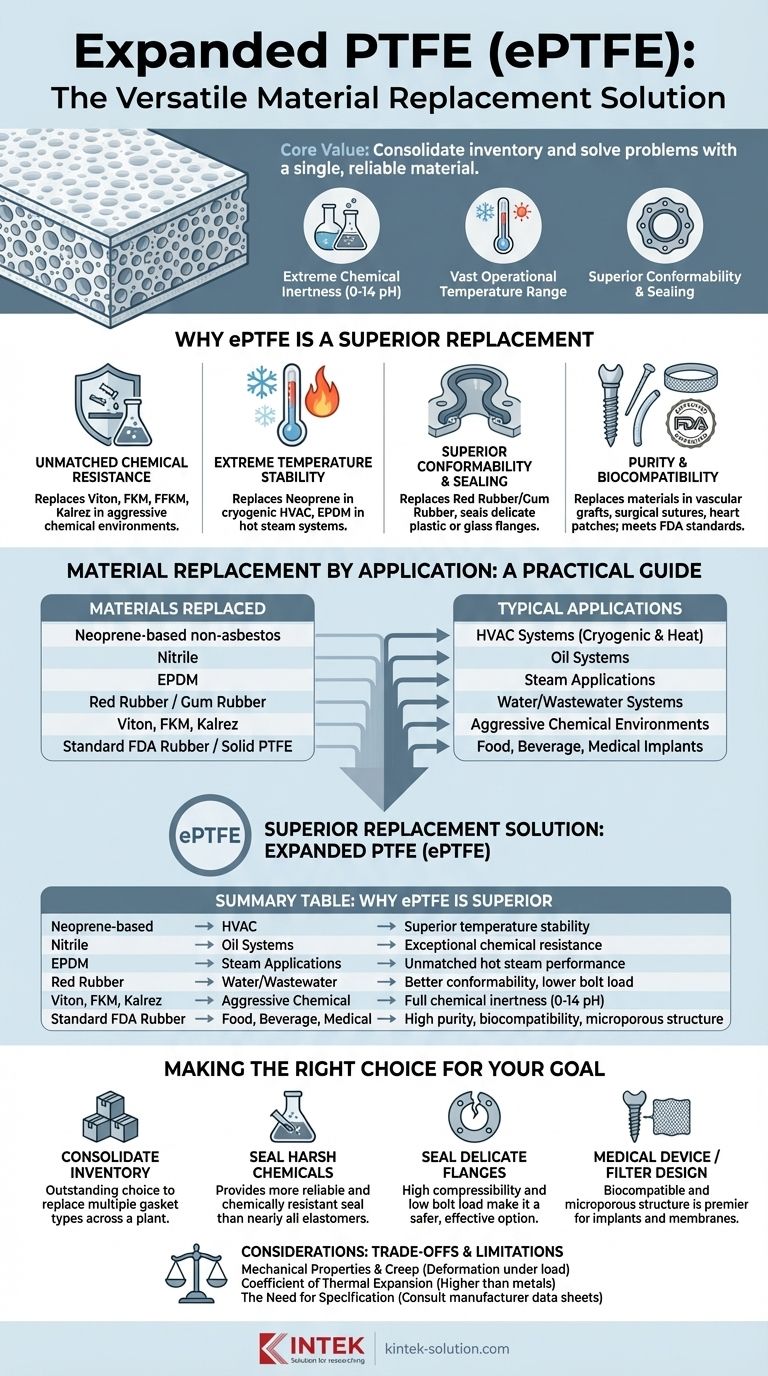

In industrial and specialized applications, Expanded PTFE (ePTFE) is a uniquely versatile material capable of replacing a wide range of conventional gaskets and components. It serves as a direct substitute for neoprene-based non-asbestos in HVAC systems, nitrile in oil systems, EPDM in steam applications, red rubber in water systems, and even high-performance elastomers like Viton, FKM, and Kalrez in aggressive chemical environments.

The core value of ePTFE is not just as a one-to-one replacement, but as a problem-solving material that consolidates inventory. Its unique combination of extreme chemical inertness, a vast operational temperature range, and superior conformability allows it to outperform and replace numerous specialized materials with a single, reliable solution.

Why ePTFE Is a Superior Replacement

The reason ePTFE can replace so many different materials stems from its fundamental properties, which are enhanced during the expansion process. This process creates a microporous structure that is soft, flexible, and chemically stable.

Unmatched Chemical Resistance

ePTFE is chemically inert across the entire 0-14 pH range, with very few exceptions.

This allows it to replace expensive, specialized elastomers like Viton, FKM, FFKM, and Kalrez in applications involving aggressive chemicals, solvents, and acids where lesser materials would quickly degrade.

Extreme Temperature Stability

Unlike most rubber and elastomer gaskets that have a narrow optimal temperature window, ePTFE performs reliably in both cryogenic and high-heat conditions.

This makes it a superior replacement for neoprene-based materials in cryogenic HVAC systems and for EPDM rubber-based non-asbestos in hot steam systems.

Superior Conformability and Sealing

The soft, flexible nature of ePTFE allows it to conform to irregular or damaged flange surfaces, creating a tight seal with lower bolt loads.

This is a significant advantage over traditional red rubber or gum rubber gaskets, especially in older water/wastewater systems. It also makes ePTFE the ideal choice for sealing delicate plastic or glass flanges that could crack under the pressure required for rigid gaskets.

Purity and Biocompatibility

ePTFE can be manufactured to meet stringent purity standards, including FDA requirements for food and beverage applications.

Its microporous structure is also biocompatible, allowing human tissue to grow into the material. This makes it a critical replacement for other materials in medical implants like vascular grafts, surgical sutures, and heart patches.

A Practical Guide to Material Replacement by Application

To select the right material, it's best to analyze the specific demands of the operating environment.

Industrial Piping and Sealing (Oil, Gas, Chemical)

In these demanding environments, ePTFE is primarily used to ensure a durable, leak-free seal against corrosive media.

It is an excellent replacement for nitrile-based materials in oil systems and for premium elastomers like Viton and FKM in chemical processing pipe flanges.

Utilities (HVAC, Steam, Water)

For general utility services, ePTFE offers a "one gasket fits all" solution that simplifies inventory and maintenance.

It reliably replaces neoprene-based non-asbestos in HVAC, EPDM in steam lines, and common red rubber gaskets in water and fire hydrant systems.

High-Purity and Medical Applications

In applications where contamination is not an option, ePTFE's purity and inertness are paramount.

It serves as an upgrade over standard FDA-approved rubber or solid PTFE in food and beverage processing. In medicine, its unique porous structure is essential for devices requiring tissue integration, such as implants and hernia repair meshes.

Specialized Applications (Filtration & Electronics)

The controlled porosity of ePTFE also makes it a high-performance membrane material.

It is used in advanced filtration systems and for fluid purification, such as diffusing ozone through ePTFE tubing to treat water. Its dielectric properties also make it a reliable electronic insulator.

Understanding the Trade-offs and Limitations

While exceptionally versatile, ePTFE is not a universal solution. An objective assessment requires understanding its limitations.

Mechanical Properties and Creep

Unfilled ePTFE is softer and more susceptible to creep (the tendency to slowly deform under a constant load) than many rigid or fiber-filled gaskets. In high-pressure applications with significant temperature cycling, this must be a design consideration.

Coefficient of Thermal Expansion

PTFE has a higher coefficient of thermal expansion than the metals used in most pipe flanges. This difference must be accounted for during joint design to maintain seal integrity across a wide temperature range.

The Need for Specification

Not all ePTFE is the same. Properties can vary between manufacturers and product grades. Always consult the manufacturer's technical data sheets to confirm compatibility with your specific chemicals, temperatures, and pressures.

Making the Right Choice for Your Goal

Your primary objective will determine if ePTFE is the most effective replacement material for your application.

- If your primary focus is consolidating gasket inventory: ePTFE is an outstanding choice to replace multiple types of rubber, elastomer, and non-asbestos sheet gaskets across a plant.

- If your primary focus is sealing in harsh chemical environments: ePTFE provides a more reliable and chemically resistant seal than nearly all elastomers, extending service life and safety.

- If your primary focus is sealing delicate or irregular flanges: The high compressibility and low required bolt load of ePTFE make it a safer and more effective option than rigid gaskets.

- If your primary focus is medical device or filter design: The biocompatible and microporous structure of ePTFE is a premier material choice for implants and high-performance membranes.

By understanding its unique properties and limitations, you can strategically leverage Expanded PTFE to enhance reliability and simplify material management in your most critical applications.

Summary Table:

| Material Replaced | Typical Application | Why ePTFE is a Superior Replacement |

|---|---|---|

| Neoprene-based non-asbestos | HVAC Systems | Superior temperature stability, from cryogenic to high-heat |

| Nitrile | Oil Systems | Exceptional chemical resistance to oils and solvents |

| EPDM | Steam Applications | Unmatched performance in hot steam environments |

| Red Rubber / Gum Rubber | Water/Wastewater Systems | Better conformability to irregular surfaces, lower bolt load |

| Viton, FKM, Kalrez | Aggressive Chemical Environments | Full chemical inertness across 0-14 pH range |

| Standard FDA Rubber / Solid PTFE | Food, Beverage, Medical | High purity, biocompatibility, and microporous structure for implants/filtration |

Ready to simplify your inventory and enhance reliability with Expanded PTFE?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom ePTFE seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you leverage the unique benefits of ePTFE to replace multiple specialized materials with a single, superior solution—from prototypes to high-volume production.

Contact our experts today to discuss your specific application requirements and discover how our custom fabrication can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support