In medical device manufacturing, virgin Polytetrafluoroethylene (PTFE) is specified for its exceptional purity, chemical inertness, and biocompatibility. Because it contains no additives or fillers, it provides a completely unadulterated material surface, which is a non-negotiable requirement for components that involve direct patient contact, such as implants, catheters, and fluid transfer tubing.

The core reason to select virgin PTFE is risk mitigation. Its inherent purity and inertness eliminate the variables and potential points of failure that fillers or recycled materials could introduce, ensuring the most stable and predictable performance in critical medical applications.

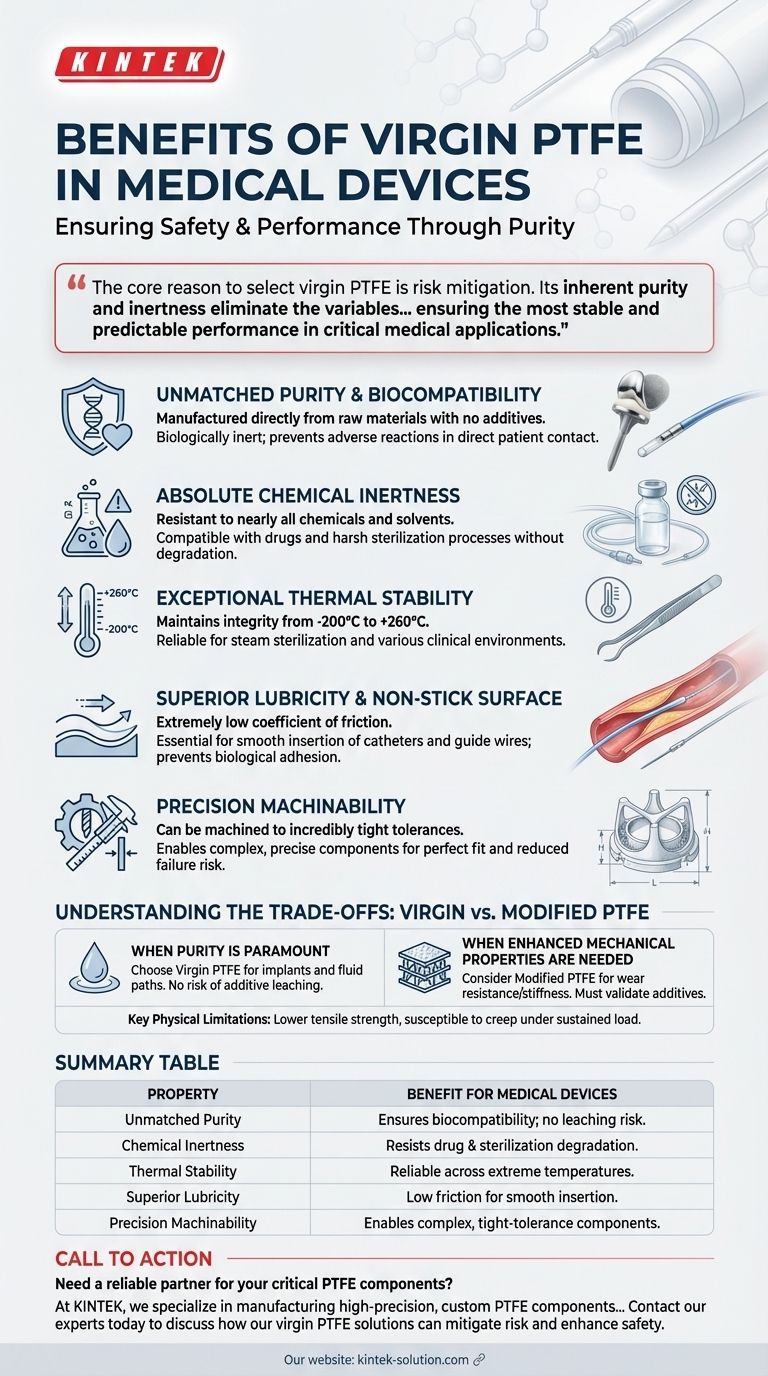

The Core Properties of Virgin PTFE

To understand why virgin PTFE is a cornerstone material in medical technology, we must examine its fundamental characteristics. Each property directly addresses a critical challenge in device design and patient safety.

Unmatched Purity and Biocompatibility

The term "virgin" signifies that the PTFE is manufactured directly from raw materials, with no reprocessed content or property-enhancing fillers.

This absolute purity is its most significant medical benefit. It ensures the material is biologically inert, meaning it will not cause an adverse reaction when it comes to contact with bodily tissue or fluids.

Absolute Chemical Inertness

Virgin PTFE is renowned for its resistance to nearly all industrial chemicals and solvents.

This is critical for medical devices that must be compatible with a wide range of drugs or withstand aggressive sterilization procedures, such as those using autoclaves or harsh chemical agents, without degrading.

Exceptional Thermal Stability

The material maintains its structural integrity and properties across an extremely broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability ensures reliable performance during steam sterilization and guarantees that the device will function as intended in various clinical environments.

Superior Lubricity and Non-Stick Surface

Virgin PTFE possesses one of the lowest coefficients of friction of any solid material, giving it an extremely slippery, non-stick surface.

For devices like catheters and guide wires, this lubricity is paramount for smooth insertion and navigation through blood vessels. The non-stick quality also minimizes the potential for biological material to adhere to the device surface.

Precision Machinability

Despite its softness, virgin PTFE can be machined to incredibly tight tolerances.

This allows for the creation of complex and precise components, ensuring a perfect fit and flawless performance in intricate medical assemblies, which directly reduces the risk of device failure.

Understanding the Trade-offs: Virgin vs. Modified PTFE

While virgin PTFE is the standard for purity, it is not the only option. Understanding its limitations is key to making an informed material decision.

When Purity is Paramount

For implants, surgical tools, and any component in a direct fluid or drug path, the choice is clear. Virgin PTFE is selected because the risk of an additive leaching into the patient or reacting with a chemical is unacceptable.

The Case for Modified PTFE

Modified PTFE includes co-polymers that can enhance certain properties. It often provides a less porous surface, longer flex life, and improved creep resistance.

These enhancements can be valuable, but they come at the cost of introducing another material. The suitability of modified PTFE depends entirely on whether those additives are permissible for the specific medical application.

Key Physical Limitations

Compared to filled or modified versions, virgin PTFE has lower tensile strength and is more susceptible to "creep" or deformation under a sustained load. It is a soft material, which is a trade-off for its flexibility and lubricity.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE requires a clear understanding of your device's primary performance requirement.

- If your primary focus is absolute biocompatibility and purity for implants or fluid paths: Virgin PTFE is the definitive and safest choice due to its complete lack of additives.

- If your primary focus is enhanced mechanical properties like wear resistance or stiffness: A filled or modified PTFE may be superior, but you must rigorously validate that the additives are approved for your specific medical use case.

- If your primary focus is navigating tortuous pathways or minimizing surface friction: Virgin PTFE's inherently low coefficient of friction makes it the ideal material for catheters and guide wires.

By understanding these fundamental properties and trade-offs, you can confidently select the material that ensures maximum safety and efficacy for your medical device.

Summary Table:

| Property | Benefit for Medical Devices |

|---|---|

| Unmatched Purity | Ensures biocompatibility; no risk of additive leaching for implants and fluid paths. |

| Chemical Inertness | Resists degradation from drugs and aggressive sterilization processes. |

| Thermal Stability | Maintains integrity from -200°C to +260°C, reliable for steam sterilization. |

| Superior Lubricity | Low friction for smooth insertion of catheters and guide wires. |

| Precision Machinability | Enables creation of complex, tight-tolerance components to reduce failure risk. |

Need a reliable partner for your critical PTFE components?

At KINTEK, we specialize in manufacturing high-precision, custom PTFE components—from seals and liners to complex labware—for the medical, semiconductor, and laboratory industries. Our commitment to precision production ensures your devices meet the highest standards of purity and performance, from prototype to high-volume orders.

Contact our experts today to discuss how our virgin PTFE solutions can mitigate risk and enhance the safety of your medical devices.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability