At its core, a PTFE bush is a high-performance, self-lubricating bearing used to reduce friction and wear between moving mechanical parts. This cylindrical sleeve is made from Polytetrafluoroethylene (PTFE), a uniquely versatile fluoropolymer. Its primary use is in applications with rotating or sliding motion, especially in environments where conventional lubricants are impractical or would fail due to chemical exposure or extreme temperatures.

The decision to use a PTFE bush is driven by its unique combination of properties. It is the material of choice when an application demands exceptional self-lubrication, near-total immunity to chemicals, and stability across a vast temperature range.

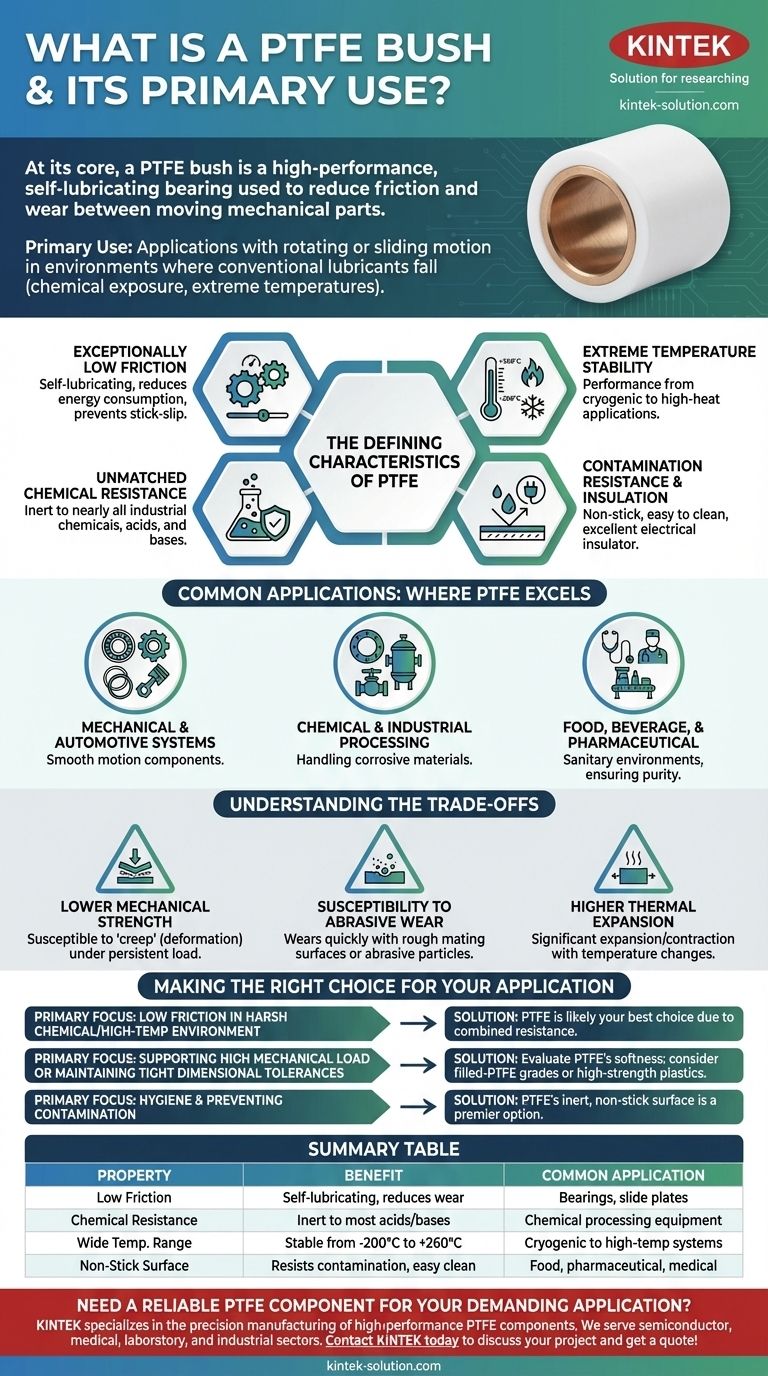

The Defining Characteristics of PTFE

To understand why PTFE is chosen for these demanding roles, we must look at its fundamental material properties. These characteristics work in concert to solve complex engineering challenges.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is what gives it its famous "non-stick" quality.

In a mechanical system, this means a PTFE bush allows parts to slide or rotate against each other with minimal resistance and without the need for external grease or oil, preventing stick-slip motion and reducing energy consumption.

Unmatched Chemical Resistance

PTFE is chemically inert and non-reactive to nearly all industrial chemicals, acids, and bases.

This makes PTFE bushings essential for equipment used in chemical processing, pharmaceuticals, and oil and gas, where components are constantly exposed to corrosive substances that would destroy metals and other plastics.

Extreme Temperature Stability

The material maintains its integrity and performance across an exceptionally wide thermal range, typically from -200°C to +260°C (-328°F to +500°F).

This allows PTFE bushes to be used in everything from cryogenic applications to high-temperature processing equipment without becoming brittle or degrading.

Contamination Resistance and Insulation

The non-stick surface of PTFE prevents materials from adhering to it, which is critical in food, beverage, and medical applications. This quality ensures purity and facilitates easy cleaning.

Additionally, PTFE is an excellent electrical insulator, making it a valuable component in electrical transformers and cable insulation.

Common Applications: Where PTFE Excels

The unique properties of PTFE allow its use across a wide spectrum of industries where performance and reliability are non-negotiable.

Mechanical and Automotive Systems

In general machinery, PTFE is used for components that require smooth, repetitive motion. This includes bearings, gears, seals, piston rings, and slide plates where low friction reduces wear and extends the life of the assembly.

Chemical and Industrial Processing

This is a primary domain for PTFE. Its chemical inertness makes it the perfect material for gaskets, valve components, and vessel linings that handle highly corrosive materials safely and reliably.

Food, Beverage, and Pharmaceutical

For sanitary environments, PTFE's non-stick surface and inert nature are indispensable. It ensures that products are not contaminated and that equipment can be cleaned thoroughly and efficiently.

Understanding the Trade-offs

No material is perfect, and being a trusted advisor means acknowledging limitations. While PTFE is a remarkable problem-solver, it has trade-offs that are critical to consider in any design.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE is a relatively soft material. It can be susceptible to "creep," which is slow deformation when placed under a persistent load.

Susceptibility to Abrasive Wear

While its friction coefficient is low, PTFE is not highly resistant to abrasion. If the mating surface is rough or if abrasive particles (like dirt or sand) are present, a PTFE bush can wear out quickly.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more significantly than most metals. Engineers must account for this in their designs by allowing for appropriate clearances to avoid binding or failure.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to the primary challenge you need to solve.

- If your primary focus is low friction in a harsh chemical or high-temperature environment: PTFE is almost certainly your best choice due to its combined resistance properties.

- If your primary focus is supporting a high mechanical load or maintaining tight dimensional tolerances: You must carefully evaluate PTFE's softness and consider filled-PTFE grades (which add materials like glass or carbon) or alternative high-strength plastics.

- If your primary focus is hygiene and preventing contamination: PTFE's inert, non-stick surface makes it a premier option for food, medical, and pharmaceutical equipment.

Ultimately, a PTFE bush is a specialized engineering solution for environments where conventional materials would quickly degrade and fail.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Bearings, slide plates |

| Chemical Resistance | Inert to most acids and bases | Chemical processing equipment |

| Wide Temp. Range | Stable from -200°C to +260°C | Cryogenic to high-temperature systems |

| Non-Stick Surface | Resists contamination, easy clean | Food, pharmaceutical, medical |

Need a reliable PTFE component for your demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bushes, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions that offer superior self-lubrication, chemical resistance, and thermal stability.

Whether you require a prototype or a high-volume order, our expertise ensures a part that meets your exact specifications and performance requirements.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications