In any valve assembly, the valve seat material is critical because it directly dictates the integrity and longevity of the seal. An unsuitable material choice is a direct path to compromised performance, leading to leaks, costly downtime, and potential safety hazards. The material must be precisely matched to the operational demands of the system.

The core challenge is not finding a single "best" material, but rather identifying the optimal one for a specific combination of fluid, temperature, and pressure. A failure in any one of these areas will inevitably lead to valve failure.

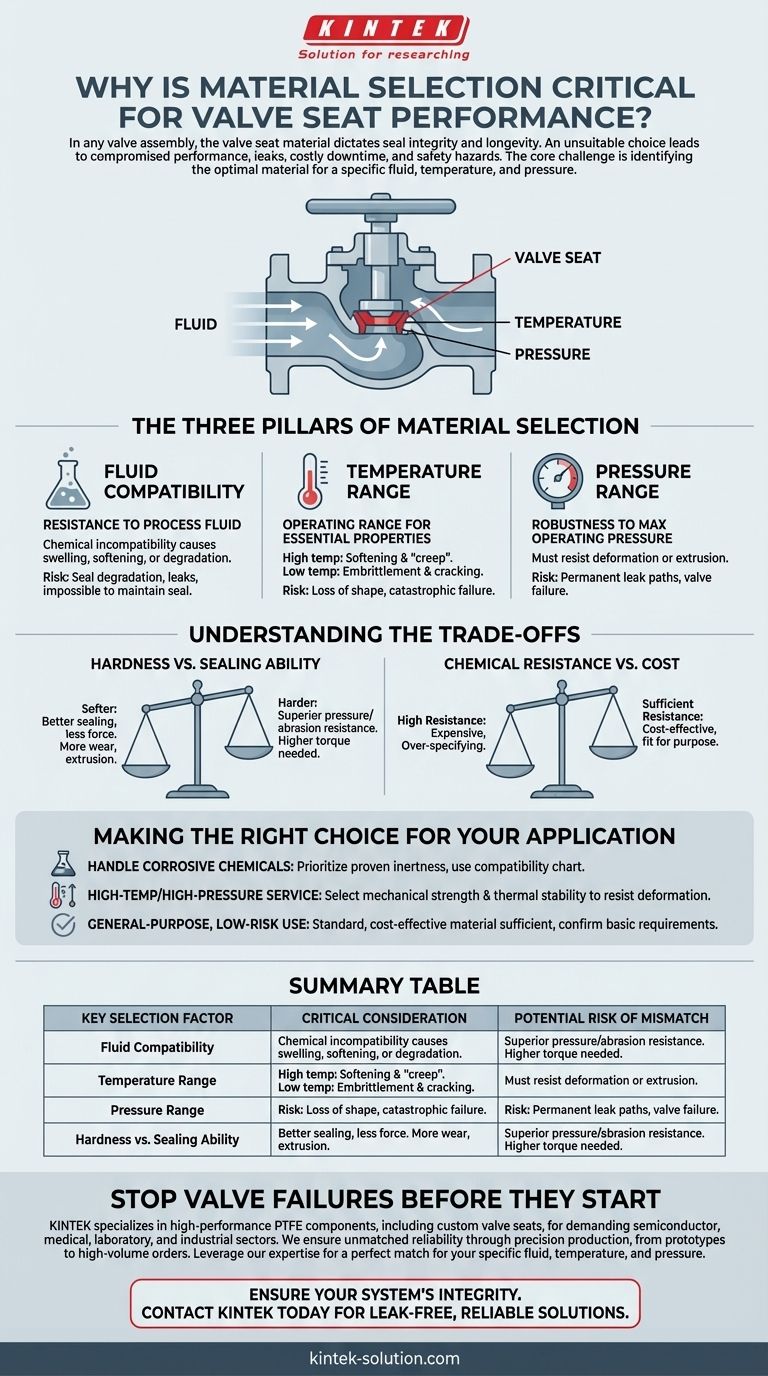

The Three Pillars of Material Selection

To ensure reliable valve performance, the seat material must be evaluated against three fundamental operational conditions. A mismatch in even one of these areas can render the valve ineffective.

Factor 1: Fluid Compatibility

The most critical factor is the material's resistance to the process fluid. Chemical incompatibility can cause the material to swell, soften, or degrade.

This degradation compromises the physical structure of the seat, making a reliable, leak-proof seal impossible to maintain over time.

Factor 2: Temperature Range

Every material has a specific temperature range within which it maintains its essential properties. Operating outside this range has severe consequences.

Too high a temperature can cause a material to soften and lose its shape, a phenomenon known as "creep." Conversely, temperatures that are too low can cause embrittlement, leading to cracking and catastrophic failure.

Factor 3: Pressure Range

The valve seat must be robust enough to withstand the system's maximum operating pressure without being deformed or extruded.

If the material is too soft for the pressure, it can be forced into the sealing gap, creating a permanent leak path and destroying the valve's functionality.

Understanding the Trade-offs

Selecting a valve seat material is rarely straightforward. It often involves balancing competing properties to find the best fit for the application.

Hardness vs. Sealing Ability

Softer materials can conform more easily to the valve body, creating a tight seal with less force. However, they are more susceptible to wear and extrusion under high pressure.

Harder materials offer superior resistance to pressure and abrasion but may require higher torque to achieve a bubble-tight seal, especially in low-pressure systems.

Chemical Resistance vs. Cost

Materials engineered for extreme chemical resistance are typically more expensive. The key is to select a material that is sufficiently resistant for the specific fluid in use.

Over-specifying a material for a simple water application adds unnecessary cost, while under-specifying it for a corrosive chemical service guarantees failure.

Making the Right Choice for Your Application

Your final decision should be guided by the most demanding aspect of your specific process conditions.

- If your primary focus is handling corrosive chemicals: Prioritize a material with proven chemical inertness for your specific fluid, verifying it against a compatibility chart.

- If your primary focus is high-temperature or high-pressure service: Select a material with the mechanical strength and thermal stability to resist deformation under load.

- If your primary focus is general-purpose, low-risk use: A standard, cost-effective material is often sufficient, but you must still confirm it meets the system's basic temperature and pressure requirements.

By systematically evaluating your material against these core factors, you ensure your valve seat selection becomes a source of system reliability, not a point of failure.

Summary Table:

| Key Selection Factor | Critical Consideration | Potential Risk of Mismatch |

|---|---|---|

| Fluid Compatibility | Chemical resistance to prevent swelling, softening, or degradation. | Seal degradation and leaks. |

| Temperature Range | Operating range to avoid softening/creep (high) or embrittlement (low). | Loss of shape or catastrophic cracking. |

| Pressure Range | Mechanical strength to resist deformation and extrusion. | Permanent leak paths from extrusion. |

| Hardness vs. Sealing | Softer for better sealing; harder for wear/pressure resistance. | Poor seal or premature wear. |

Stop Valve Failures Before They Start

Selecting the perfect valve seat material is complex, but you don't have to navigate the trade-offs between chemical resistance, temperature stability, and pressure tolerance alone. KINTEK specializes in manufacturing high-performance PTFE components, including custom valve seats, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure your components deliver unmatched reliability. Whether you need a prototype for a new design or high-volume orders for critical infrastructure, our custom fabrication expertise ensures a perfect match for your specific fluid, temperature, and pressure requirements.

Ensure your system's integrity. Contact KINTEK today to discuss your valve seat needs and leverage our material science expertise for a leak-free, reliable solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance