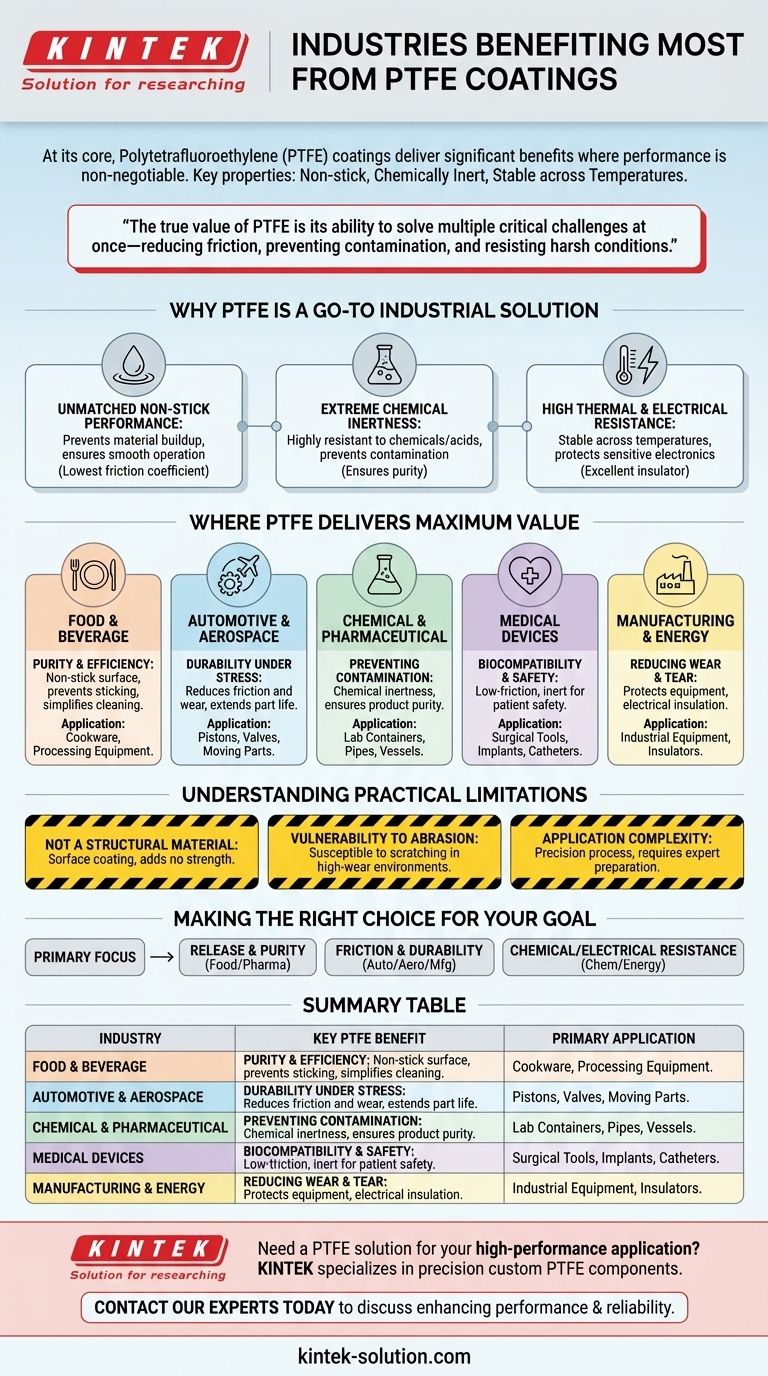

At its core, Polytetrafluoroethylene (PTFE) coatings deliver the most significant benefits to industries where performance is non-negotiable. These include food and beverage, automotive, aerospace, chemical processing, and medical device manufacturing. The value of PTFE in these sectors comes from its unique combination of properties: it is exceptionally non-stick, chemically inert, and stable across a wide range of temperatures.

The true value of PTFE is not found in a single feature, but in its unique ability to solve multiple critical challenges at once—reducing friction, preventing contamination, and resisting harsh conditions—making it indispensable across a wide spectrum of demanding industries.

Why PTFE Is a Go-To Industrial Solution

The widespread adoption of PTFE isn't accidental. It stems from a few core physical properties that make it an exceptional problem-solver in environments where other materials would quickly fail.

Unmatched Non-Stick Performance

PTFE has one of the lowest coefficients of friction of any solid material, which is why it is famous for its non-stick, or release, characteristics. This property is crucial for preventing material buildup and ensuring smooth operation.

Extreme Chemical Inertness

PTFE is highly resistant to nearly all chemicals, acids, and solvents. This chemical resistance ensures that the coating does not degrade or contaminate the substances it comes into contact with, which is vital for purity.

High Thermal and Electrical Resistance

This material maintains its stability and properties across a broad temperature range. Furthermore, it is an excellent electrical insulator, making it a key component in protecting sensitive electronics from electrical shorts and environmental factors.

Where PTFE Delivers Maximum Value

Different industries leverage specific PTFE properties to solve their most pressing challenges, from ensuring food safety to enhancing the durability of critical aerospace components.

Food & Beverage: Purity and Efficiency

In this sector, PTFE is used for its non-stick surface on cookware and industrial food processing equipment. This prevents food from sticking, simplifies cleaning, and ensures a hygienic, uncontaminated production line.

Automotive & Aerospace: Durability Under Stress

Components like pistons, valves, and other moving parts are often coated with PTFE to reduce friction and wear. This improves efficiency, extends the life of the parts, and ensures reliability in high-stress engines and mechanical systems.

Chemical & Pharmaceutical: Preventing Contamination

Due to its chemical inertness, PTFE is the ideal coating for lab containers, pipes, and vessels. It prevents reactions between the container and its contents, ensuring the purity of the product and the integrity of the equipment.

Medical Devices: Biocompatibility and Safety

PTFE's low-friction and inert properties are critical for medical applications. It is used to coat surgical tools, implants, and catheters to improve patient safety and device performance.

Manufacturing & Energy: Reducing Wear and Tear

In general manufacturing, PTFE coatings protect industrial equipment from wear and corrosion. In the energy sector, its use as an electrical insulator on transformers and circuit breakers is essential for operational safety and reliability.

Understanding the Practical Limitations

While incredibly versatile, PTFE is not a universal solution. Understanding its trade-offs is crucial for proper application and to avoid common pitfalls.

Not a Structural Material

PTFE is a surface coating, not a structural component. It provides surface properties but does not add significant strength or rigidity to the underlying part.

Vulnerability to Abrasion

While it has a low coefficient of friction, PTFE coatings can be susceptible to scratching and heavy physical abrasion. In high-wear mechanical environments, its lifespan must be carefully considered.

Application Complexity

Applying a durable, high-quality PTFE coating is a precise industrial process. It requires expert surface preparation and curing to ensure proper adhesion and performance, making it difficult for on-site repairs.

Making the Right Choice for Your Goal

To determine if PTFE is the right choice, align its primary benefits with your specific industrial goal.

- If your primary focus is release and purity: PTFE is an industry standard for food processing, pharmaceutical, and medical applications where preventing sticking and contamination is paramount.

- If your primary focus is friction reduction and durability: PTFE is an excellent choice for automotive, aerospace, and manufacturing components that require smooth operation and an extended service life.

- If your primary focus is chemical or electrical resistance: PTFE provides a reliable barrier in chemical processing, energy, and electronics where protection from corrosion or electrical current is essential.

Ultimately, PTFE's power lies in its ability to enhance and protect critical components in the world's most demanding environments.

Summary Table:

| Industry | Key PTFE Benefit | Primary Application |

|---|---|---|

| Food & Beverage | Non-stick & Purity | Cookware, Processing Equipment |

| Automotive & Aerospace | Friction Reduction | Pistons, Valves, Moving Parts |

| Chemical & Pharmaceutical | Chemical Inertness | Lab Containers, Pipes, Vessels |

| Medical Devices | Biocompatibility & Safety | Surgical Tools, Implants, Catheters |

| Manufacturing & Energy | Wear & Electrical Resistance | Industrial Equipment, Insulators |

Need a PTFE solution for your high-performance application?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver the durability and chemical resistance your operations demand, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE components can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining