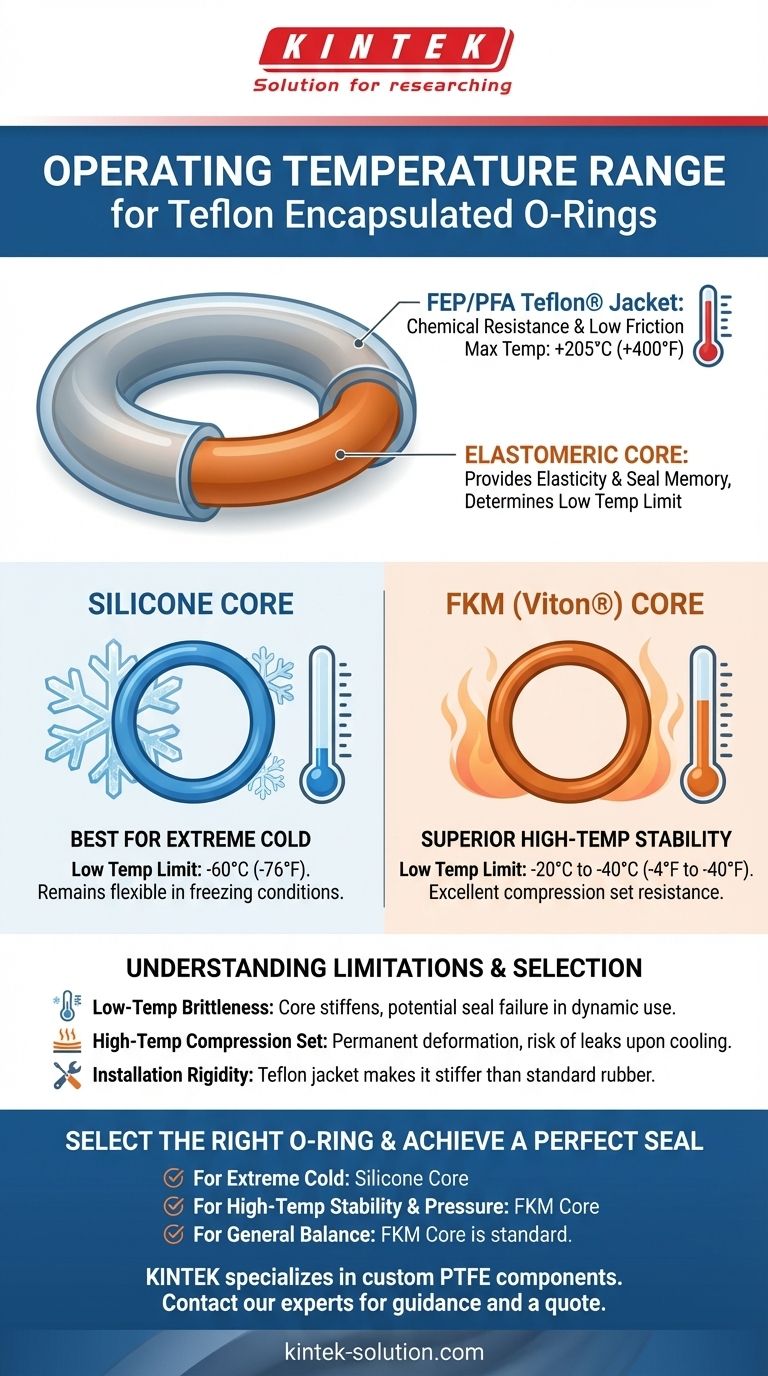

In short, the operating temperature for Teflon encapsulated O-rings typically ranges from -60°C to +205°C (-76°F to +400°F). However, this range is not absolute; it is fundamentally determined by the material used for the inner core, which provides the seal's elasticity.

The key takeaway is that an encapsulated O-ring is a two-part system. While the outer Teflon shell provides chemical inertness, the inner elastomeric core (usually Silicone or FKM) dictates the seal's effective temperature range and mechanical performance.

Deconstructing the Encapsulated O-Ring

To understand the temperature limits, you must first understand the construction. These seals are not solid Teflon; they consist of two distinct components working together.

The Role of the Teflon Encapsulation (FEP/PFA)

The outer jacket is a thin, seamless layer of fluoropolymer, most commonly FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy).

This shell provides the O-ring's primary benefits: outstanding chemical resistance and a low coefficient of friction. The upper temperature limit is often dictated by this FEP or PFA jacket, which typically operates up to +205°C (+400°F).

The Critical Function of the Elastomeric Core

The inner core is a solid elastomer that provides the O-ring with its "memory" and elasticity. This core is what provides the physical force required to maintain a seal.

Without this flexible core, the rigid Teflon jacket would be unable to compress and rebound effectively, especially during temperature fluctuations. The choice of core material is the most significant factor in the O-ring's low-temperature performance.

How Core Material Dictates the Temperature Range

The overall temperature rating is governed by the weakest link in this two-part system. The core material determines how the seal will behave at the low end of the spectrum.

Silicone Core: For Extreme Lows

A silicone core provides the best low-temperature performance. Silicone remains flexible at extremely cold temperatures, allowing the O-ring to maintain its sealing force.

O-rings with a silicone core can typically reach the lowest effective temperature of -60°C (-76°F).

FKM (Viton®) Core: The High-Performance Standard

FKM is the most common core material due to its excellent compression set resistance, meaning it resists permanent flattening under pressure, especially at higher temperatures.

However, FKM does not perform as well as silicone in extreme cold. O-rings with an FKM core are generally rated for a low temperature of -20°C to -40°C (-4°F to -40°F).

Understanding the Trade-offs and Limitations

While offering a unique combination of benefits, encapsulated O-rings are not a universal solution. Understanding their limitations is critical for successful implementation.

Low-Temperature Brittleness

As the core material approaches its low-temperature limit, it stiffens and loses its ability to "push back" against the sealing surfaces. This loss of elasticity can lead to seal failure, particularly in dynamic applications or during thermal cycling.

High-Temperature Compression Set

At the upper end of the temperature range, the elastomeric core can permanently deform under pressure, a phenomenon known as compression set. When the system cools, the O-ring may not rebound to its original shape, creating a leak path.

Installation Rigidity

The Teflon jacket makes the O-ring significantly stiffer than a standard rubber O-ring. This can make installation more difficult and increases the risk of damaging the thin encapsulation if it is stretched excessively or forced over sharp edges.

Selecting the Right O-Ring for Your Application

Your choice must be guided by the specific demands of your operating environment.

- If your primary focus is extreme cold performance: Choose an encapsulated O-ring with a silicone core to ensure sealing integrity down to -60°C.

- If your primary focus is high-temperature stability and pressure: An FKM core is the superior choice, providing better resistance to compression set and ensuring a more reliable seal near the 205°C limit.

- If your primary focus is a balance of chemical resistance and general performance: The FKM core is the standard, most widely used option that covers a broad range of industrial applications.

Ultimately, making an informed choice requires looking beyond the Teflon shell and understanding the core material that provides the seal's essential mechanical properties.

Summary Table:

| Core Material | Typical Low Temp. Limit | High Temp. Limit (FEP/PFA Jacket) | Key Characteristic |

|---|---|---|---|

| Silicone | -60°C (-76°F) | +205°C (+400°F) | Best for extreme low temperatures |

| FKM (Viton®) | -20°C to -40°C (-4°F to -40°F) | +205°C (+400°F) | Superior high-temp stability & compression set resistance |

Need a Reliable Seal for Demanding Conditions?

Selecting the right encapsulated O-ring is critical for your application's success. The core material—whether Silicone for extreme cold or FKM for high-temperature stability—directly impacts performance and longevity.

KINTEK specializes in manufacturing high-performance PTFE components, including custom Teflon encapsulated O-rings. We serve the semiconductor, medical, laboratory, and industrial sectors, providing precision production from prototypes to high-volume orders.

Let us help you achieve a perfect, leak-free seal. Our experts can guide you to the optimal material combination for your specific temperature and chemical requirements.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech