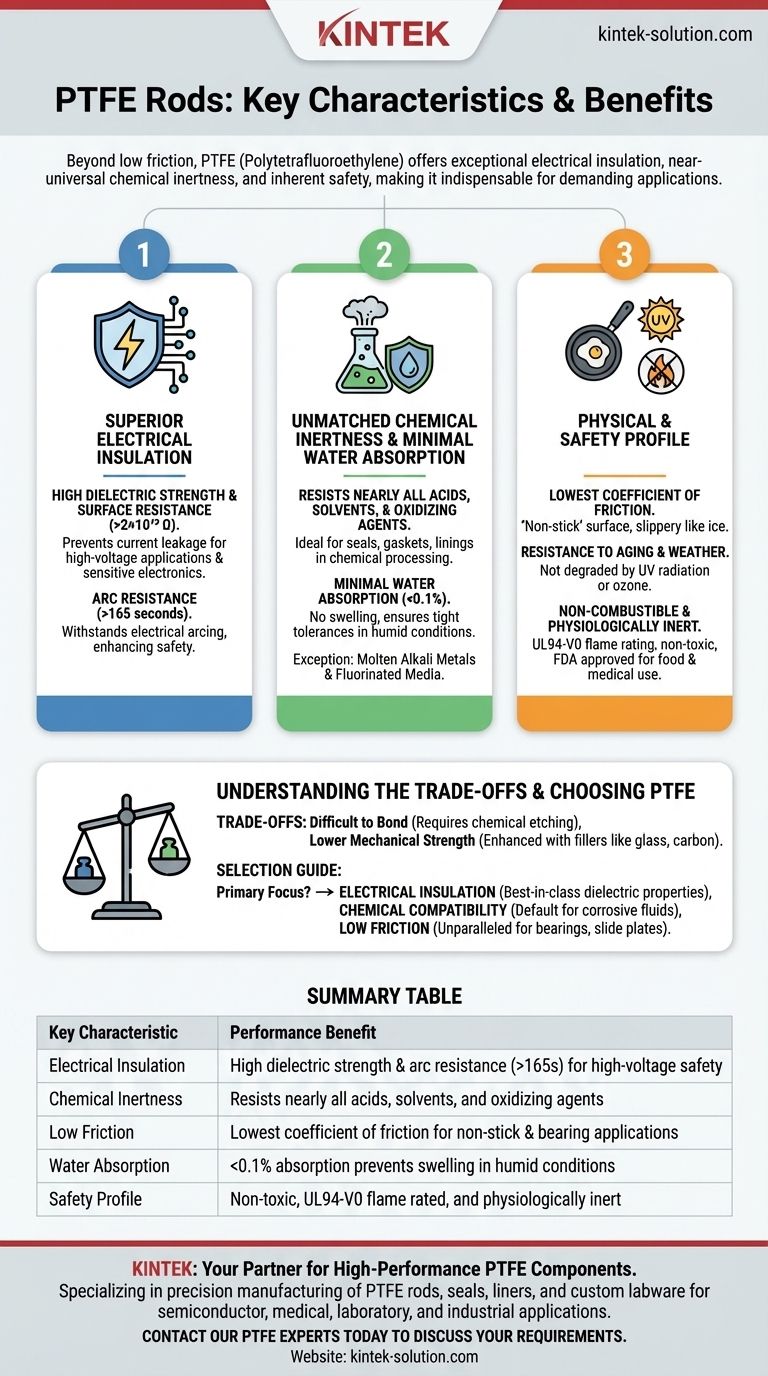

Beyond its famous low-friction surface, PTFE (Polytetrafluoroethylene) possesses a unique combination of exceptional electrical insulation, near-universal chemical inertness, and inherent safety. Its characteristics include a surface resistance greater than 2×10¹³ Ω, an arc resistance exceeding 165 seconds, and virtually zero water absorption, making it a highly stable and reliable material for demanding applications.

The true value of PTFE lies not in a single characteristic, but in the synergy of its properties. Its ability to simultaneously resist extreme temperatures, aggressive chemicals, and electrical current makes it an indispensable problem-solver in environments where other materials would quickly fail.

Unpacking the Electrical and Chemical Properties

The performance of PTFE in harsh industrial settings is defined by its remarkable stability when exposed to electrical stress and corrosive agents.

Superior Electrical Insulation

PTFE is one of the best-known electrical insulators. Its high dielectric strength and surface resistance prevent electrical current from flowing where it shouldn't, which is critical for high-voltage applications and sensitive electronics.

Furthermore, its arc resistance of over 165 seconds means it can withstand electrical arcing for a significant duration before breaking down, enhancing safety and reliability.

Unmatched Chemical Inertness

PTFE offers outstanding resistance to a vast range of chemicals, including strong acids, oxidizing agents, and nearly all organic solvents. This makes it ideal for seals, gaskets, and linings in chemical processing equipment.

The only notable exceptions to this near-universal inertness are molten alkali metals and certain fluorinated media.

Minimal Water Absorption

With a water absorption rate below 0.1%, PTFE rods do not swell or change their dimensional or electrical properties when exposed to moisture. This stability is crucial for components that require tight tolerances in humid or submerged conditions.

Examining the Physical and Safety Profile

Beyond its chemical and electrical performance, PTFE’s physical behavior and inherent safety are key to its versatility.

The Ultimate Non-Stick Surface

PTFE has the lowest coefficient of friction of any known solid material, making it even more slippery than ice. This non-adhesive, or "non-stick," quality prevents other materials from bonding to its surface, which is vital for applications like low-friction bearings and release surfaces.

Resistance to Aging and Weather

When exposed to the environment, PTFE rods demonstrate excellent resistance to aging. They are not degraded by exposure to UV radiation from sunlight or ozone, maintaining their mechanical integrity over long periods.

Non-Combustible and Physiologically Inert

PTFE is non-combustible and has a high ignition resistance, earning it a UL94-V0 flame rating, meaning it does not promote flame spread.

Critically, it is also non-toxic, odorless, and physiologically inert. This biocompatibility makes it safe for use in food processing (FDA approved) and certain medical applications.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not without its limitations. Understanding these is key to successful implementation.

The Challenge of Bonding

The same non-adhesive quality that makes PTFE an excellent non-stick surface also makes it extremely difficult to bond to other materials using conventional adhesives. Attaching PTFE often requires specialized surface treatments like chemical etching to create a bondable surface.

Relative Mechanical Properties

Compared to high-performance engineering plastics, PTFE has lower tensile strength and wear resistance. Its properties can be enhanced with fillers (like glass, carbon, or bronze), but in its virgin state, it is not typically chosen for high-load structural applications.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on the need for performance in extreme conditions where other materials are unsuitable.

- If your primary focus is electrical insulation: PTFE provides best-in-class dielectric properties and arc resistance, especially in chemically aggressive or high-temperature environments.

- If your primary focus is chemical compatibility: PTFE is the default choice for seals, linings, and components handling highly corrosive fluids, with very few known exceptions.

- If your primary focus is a low-friction, non-stick surface: PTFE's unparalleled low coefficient of friction makes it ideal for high-performance bearings, slide plates, and non-stick coatings.

Ultimately, PTFE is the premier material for applications where reliability under a combination of thermal, chemical, and electrical stress is non-negotiable.

Summary Table:

| Key Characteristic | Performance Benefit |

|---|---|

| Electrical Insulation | High dielectric strength & arc resistance (>165s) for high-voltage safety |

| Chemical Inertness | Resists nearly all acids, solvents, and oxidizing agents |

| Low Friction | Lowest coefficient of friction for non-stick & bearing applications |

| Water Absorption | <0.1% absorption prevents swelling in humid conditions |

| Safety Profile | Non-toxic, UL94-V0 flame rated, and physiologically inert |

Need high-performance PTFE components that excel under extreme conditions?

At KINTEK, we specialize in precision manufacturing of PTFE rods, seals, liners, and custom labware. Our expertise ensures your components deliver unmatched reliability in semiconductor, medical, laboratory, and industrial applications—from prototypes to high-volume orders.

Contact our PTFE experts today to discuss your specific requirements and discover how our custom fabrication can solve your most challenging material problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance