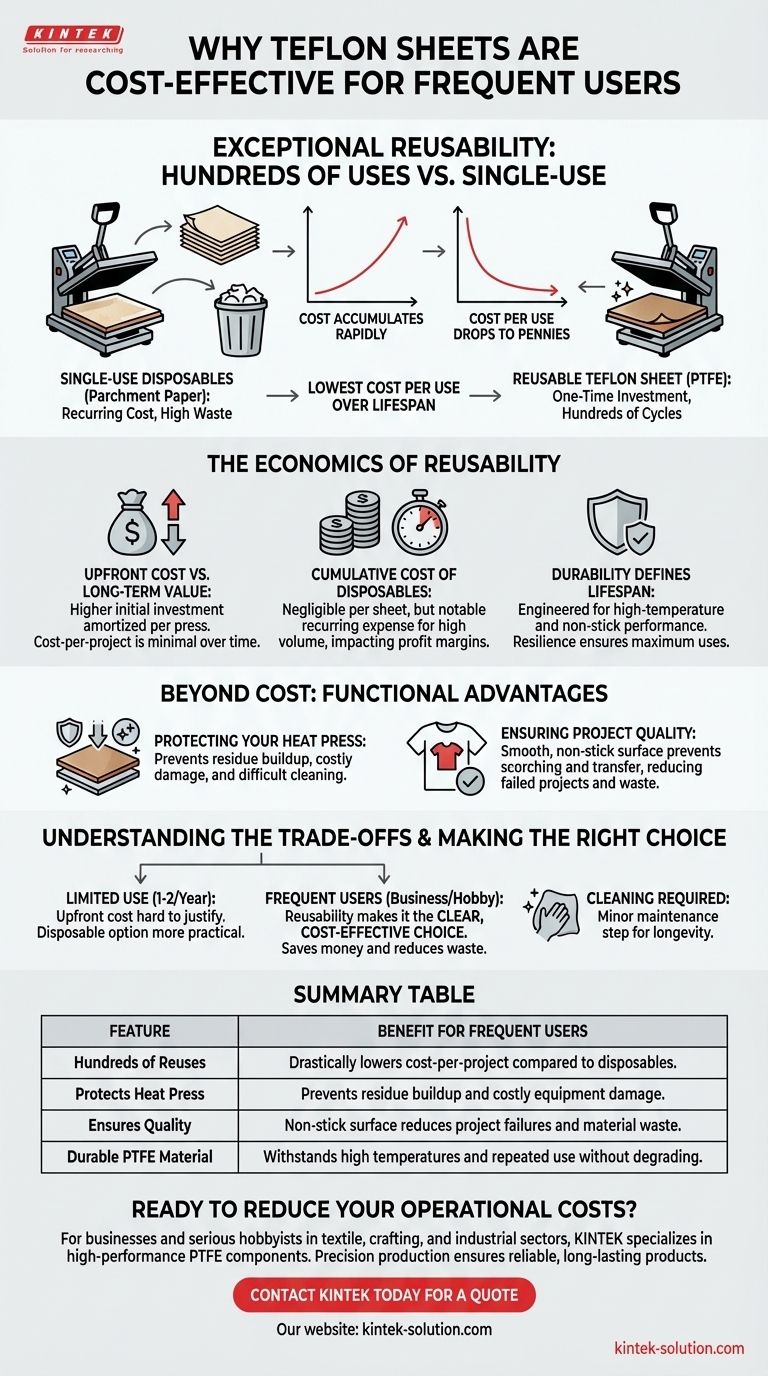

In short, Teflon sheets are cost-effective for frequent users because of their exceptional reusability. Unlike single-use alternatives such as parchment paper that must be discarded after one or a few uses, a single Teflon sheet can withstand hundreds of heat-pressing cycles, dramatically lowering the cost per use over its lifespan.

The true cost of a tool isn't its purchase price, but its cost per use. While single-use sheets seem cheaper initially, their recurring expense quickly surpasses the one-time investment in a durable, reusable Teflon sheet for anyone running regular projects.

The Economics of Reusability

For any regular crafting or production workflow, a primary goal is to minimize recurring costs without sacrificing quality. This is the core value proposition of Teflon.

Upfront Cost vs. Long-Term Value

A Teflon sheet requires a higher initial investment compared to a roll of parchment or butcher paper. However, this cost is amortized with every single press.

Because one sheet can handle hundreds of applications, the cost-per-project quickly drops to mere pennies, ultimately representing a significant saving over time.

The Cumulative Cost of Disposables

Single-use papers are a consumable expense. While the cost of one sheet is negligible, it becomes a notable line item when you are pressing dozens or hundreds of items per month.

This recurring cost directly eats into the profit margins of a business or the budget of a serious hobbyist.

Durability Defines the Lifespan

Teflon (PTFE) is engineered for high-temperature and non-stick performance. This inherent durability is what allows it to be used repeatedly without degrading, tearing, or losing its protective qualities.

This resilience ensures you get the maximum number of uses from your initial investment, directly driving its cost-effectiveness.

Beyond Cost: The Functional Advantages

While the financial argument is compelling, the operational benefits also contribute to its overall value by protecting your equipment and improving project outcomes.

Protecting Your Heat Press

A primary function of a cover sheet is to protect the upper platen of your heat press from inks, adhesives, and vinyl residue.

A buildup of this residue can lead to difficult cleaning, uneven heating, or even permanent damage to your press—a far more significant cost than the sheet itself.

Ensuring Project Quality

The smooth, non-stick surface of a Teflon sheet helps prevent scorching on sensitive fabrics and ensures that no adhesive or ink transfers back onto your garment.

This consistency reduces the rate of failed projects. Fewer mistakes mean less money wasted on ruined blank garments and vinyl, further lowering your total operational costs.

Understanding the Trade-offs

No solution is perfect for every scenario. Objectivity requires acknowledging the potential downsides.

The Initial Investment

For a user who only plans to make one or two T-shirts a year, the upfront cost of a Teflon sheet may be hard to justify. In this specific case, a cheaper disposable option could be more practical.

Required Cleaning

Unlike a disposable sheet that you can simply throw away, a Teflon sheet must be wiped clean after use if any residue is present. This is a minor but necessary maintenance step to ensure its longevity and prevent cross-contamination between projects.

Making the Right Choice for Your Workflow

Your decision should be based on your project volume and long-term goals.

- If your primary focus is running a business or frequent hobby projects: The reusability of a Teflon sheet makes it the clear, cost-effective choice that will save you money and reduce waste over time.

- If your primary focus is a single, one-off project: The upfront cost of a Teflon sheet is likely unnecessary, and a more affordable option like parchment paper will suffice.

Ultimately, choosing the right tool comes down to understanding the relationship between frequency, cost, and long-term value.

Summary Table:

| Feature | Benefit for Frequent Users |

|---|---|

| Hundreds of Reuses | Drastically lowers cost-per-project compared to disposables. |

| Protects Heat Press | Prevents residue buildup and costly equipment damage. |

| Ensures Quality | Non-stick surface reduces project failures and material waste. |

| Durable PTFE Material | Withstands high temperatures and repeated use without degrading. |

Ready to reduce your operational costs and protect your equipment?

For businesses and serious hobbyists in the textile, crafting, and industrial sectors, the long-term value of a durable Teflon sheet is clear. At KINTEK, we specialize in manufacturing high-performance PTFE components like heat press sheets, seals, and liners. Our precision production ensures you get a reliable, long-lasting product that maximizes your investment.

Whether you need a standard size or a custom-fabricated solution for your specific workflow, we can help—from prototypes to high-volume orders.

Contact KINTEK today to discuss your needs and get a quote for a Teflon sheet that will save you money with every use!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why are PTFE lined check valves ideal for commercial environments? Ensure System Integrity in Corrosive Applications

- How do PTFE seals contribute to reducing vehicle emissions? Achieve Cleaner, More Efficient Vehicles

- What are PTFE compounds and how are they used? Enhance Performance for Demanding Applications

- How do PTFE seals benefit the food and pharmaceutical industries? Ensuring Product Purity and Compliance

- What role does thermal history play in the processing of PTFE? Master Heat Control for Superior Components

- How do PTFE lined valves provide excellent chemical resistance? The Ultimate Guide to Inert Fluid Handling

- What are the disadvantages of solid Teflon O-rings? Key Limitations for Reliable Sealing

- What are typical applications of TFE Encapsulated Gaskets? Ideal for Chemical & High-Purity Seals