PTFE seals are indispensable in the food and pharmaceutical industries because they provide a unique combination of chemical inertness, regulatory compliance, and operational resilience. This ensures that sealing components do not compromise product purity, react with sensitive ingredients, or fail under the aggressive cleaning protocols required to maintain sanitary conditions.

In environments where product safety and purity are paramount, the central benefit of PTFE is its non-contaminating nature. Its compliance with FDA standards and inherent non-reactivity mean the seal itself never becomes a risk, providing a reliable barrier that protects both the product and the processing equipment.

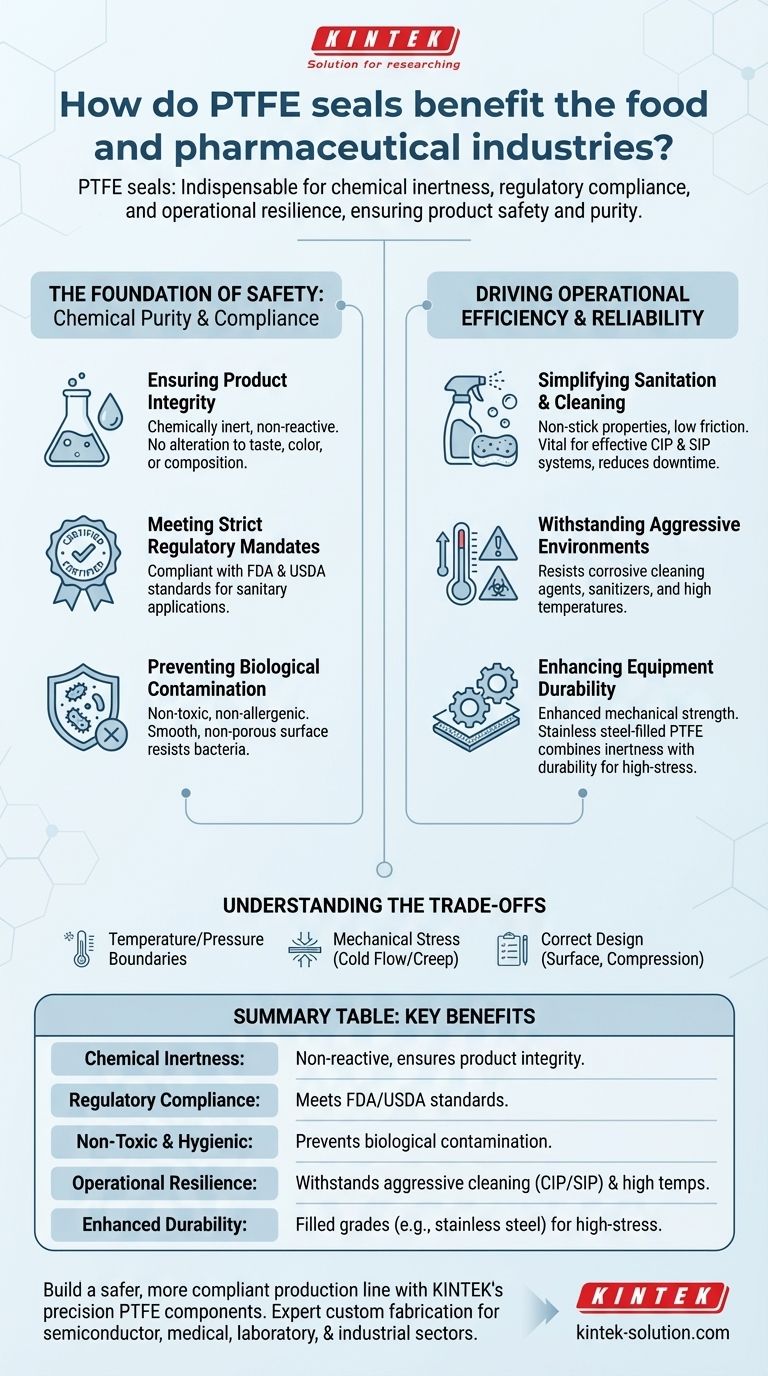

The Foundation of Safety: Chemical Purity and Compliance

The primary role of a seal in these industries is to perform its function without adding anything to the product. PTFE excels at this due to its fundamental material properties.

Ensuring Product Integrity

PTFE is chemically inert, meaning it is non-reactive. It will not react with or degrade when exposed to sensitive pharmaceuticals, food ingredients, or beverages.

This property ensures the final product's taste, color, and chemical composition remain completely unaltered by contact with the sealing material.

Meeting Strict Regulatory Mandates

Materials used in food and pharmaceutical processing are subject to stringent regulations. PTFE is widely available in grades that are compliant with FDA and USDA standards.

Using certified PTFE components like bellows, gaskets, and valve linings is a critical step in ensuring an entire production system meets regulatory approval for sanitary applications.

Preventing Biological Contamination

Beyond chemical purity, biological safety is essential. PTFE is non-toxic, non-allergenic, and non-carcinogenic.

Furthermore, its smooth, non-porous surface resists the attachment and growth of bacteria, which is a crucial advantage in maintaining strict hygiene standards.

Driving Operational Efficiency and Reliability

A safe seal must also be a durable one. PTFE's physical properties allow it to withstand the demanding operational cycles of food and pharmaceutical manufacturing.

Simplifying Sanitation and Cleaning

PTFE is well-known for its non-stick properties. This low-friction surface makes equipment far easier to clean, as product residue and contaminants do not adhere to it.

This characteristic is vital for effective Clean-in-Place (CIP) and Sterilization-in-Place (SIP) systems, reducing downtime and ensuring a consistently sanitary environment.

Withstanding Aggressive Environments

Processing equipment must undergo frequent and harsh cleaning and sterilization regimens. PTFE demonstrates exceptional resistance to corrosive cleaning agents, sanitizers, and high temperatures.

This ensures the seals maintain their integrity and do not degrade over time, preventing costly leaks and equipment failure.

Enhancing Equipment Durability

In addition to chemical resistance, PTFE can be enhanced for mechanical strength. For example, stainless steel-filled PTFE combines the inertness of PTFE with the durability of steel.

This makes it ideal for high-stress applications in processing machinery, offering both corrosion resistance and the strength needed to ensure a long service life and reduce maintenance costs.

Understanding the Trade-offs

While highly effective, no material is a universal solution. Understanding PTFE's limitations is key to its proper application.

Temperature and Pressure Boundaries

Different grades of PTFE have specific operating temperature and pressure limits. Exceeding these can lead to material degradation or mechanical failure, so selecting a grade appropriate for the application's demands is critical.

Considerations for Mechanical Stress

Unfilled, or "virgin," PTFE can be susceptible to cold flow or "creep" under high mechanical loads. For applications involving significant pressure or structural stress, a filled PTFE (e.g., with stainless steel or glass) is often the superior choice.

Importance of Correct Design

The benefits of PTFE are only realized when the seal or component is correctly designed and installed. Factors like surface finish, compression, and housing design are crucial for achieving a reliable, long-lasting seal.

Making the Right Choice for Your Application

Selecting the correct PTFE solution depends entirely on the specific demands of your process.

- If your primary focus is absolute product purity for direct contact: Use virgin, FDA-compliant PTFE grades to guarantee no fillers or additives can leach into your product.

- If your primary focus is mechanical durability in high-wear equipment: Choose a filled PTFE, such as stainless steel-filled, to provide the necessary strength and resistance to wear and tear.

- If your primary focus is withstanding aggressive CIP/SIP protocols: Confirm the selected PTFE grade has the chemical and thermal resistance required for your specific cleaning agents and sterilization cycles.

Ultimately, choosing the right PTFE component is a foundational decision for building a safe, compliant, and efficient production system.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Non-reactive, ensuring product integrity (taste, color, composition). |

| Regulatory Compliance | Meets FDA/USDA standards for sanitary applications. |

| Non-Toxic & Hygienic | Prevents biological contamination with a smooth, non-porous surface. |

| Operational Resilience | Withstands aggressive cleaning (CIP/SIP) and high temperatures. |

| Enhanced Durability | Filled grades (e.g., stainless steel) offer strength for high-stress applications. |

Build a safer, more compliant production line with KINTEK's precision PTFE components.

As experts in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical need for purity and reliability. Whether you require FDA-compliant virgin PTFE for direct product contact or durable filled PTFE for high-wear equipment, KINTEK delivers.

We partner with you from prototype to high-volume production to ensure your seals, liners, and labware meet the exacting demands of your process. Let us help you enhance product safety and operational efficiency.

Contact KINTEK today to discuss your specific application needs and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components